PLC Analog I/O Potential Problems – Troubleshooting and Solutions

- 〡

- 〡 by WUPAMBO

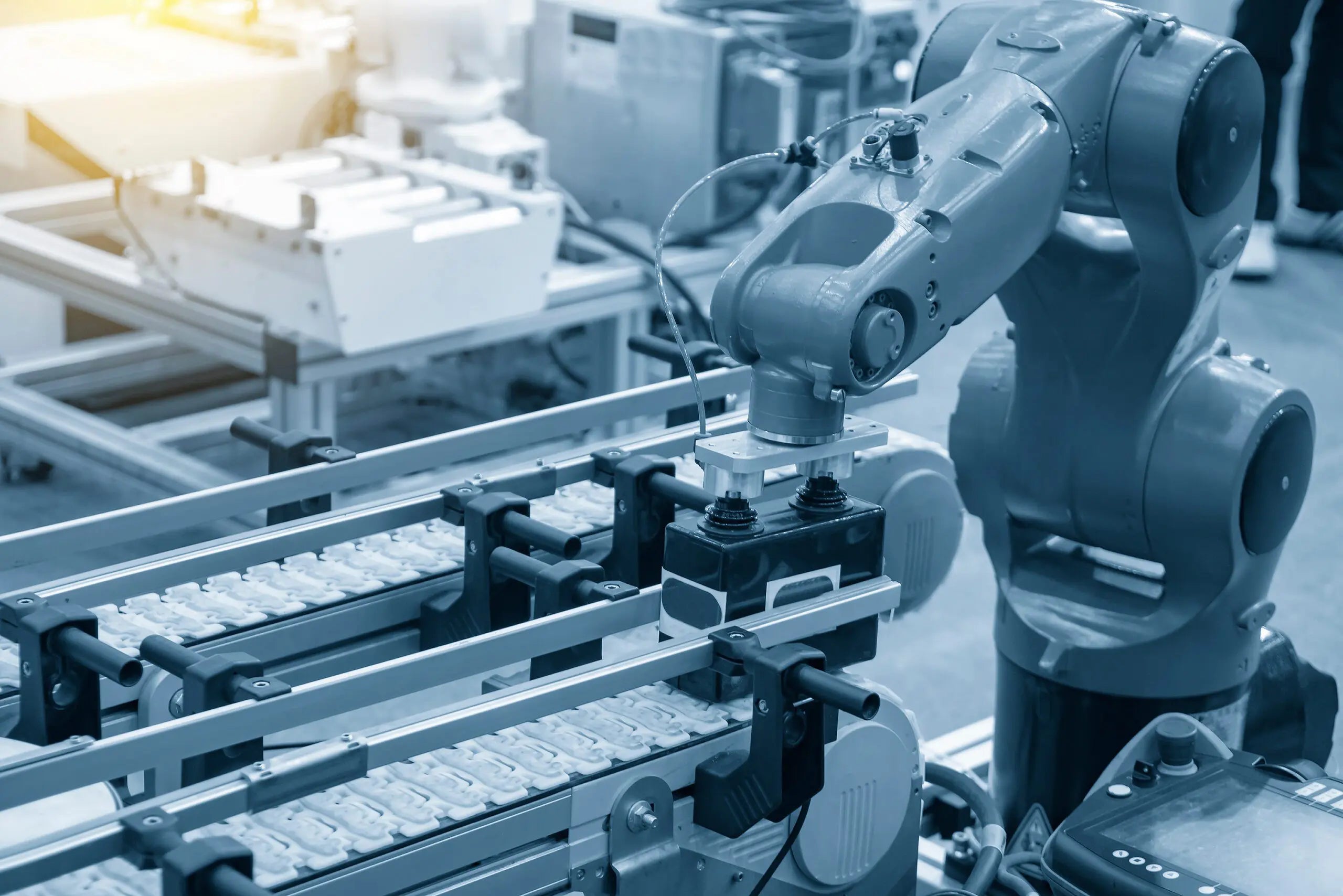

Analog I/O channels in programmable logic controllers (PLCs) play a critical role in industrial automation. These channels handle continuous signals for process control, such as temperature, pressure, and speed. When analog signals malfunction, incorrect readings can disrupt entire systems. This article explores common PLC analog I/O problems, their causes, and practical troubleshooting strategies based on real-world automation experience.

Understanding Analog I/O in PLC Systems

In most control systems, analog I/O signals are internally represented as numerical register values. Engineers can manipulate these values using mathematical operations within the PLC software. Advanced PLCs support multiple numerical formats such as binary, octal, decimal, or hexadecimal, allowing flexible scaling and conversion.

However, compact or cost-effective PLCs may have limited number systems. In such cases, converting between the PLC’s internal format and decimal becomes essential for accurate calibration and troubleshooting.

Example: Verifying Analog Input Accuracy

Consider a scenario where a voltage of 3.5 V is applied to an 8-bit, 5 V unipolar analog input. If the PLC register shows a raw value of 179, the corresponding input voltage equals:

3.496 V = (179 × 5) / 2⁸

With a resolution of approximately 0.0195 V per bit, this result is well within acceptable tolerance, confirming that the analog input works correctly.

Author insight: Regular calibration and verification of analog inputs ensure consistent process accuracy and prevent long-term drift in control systems.

Common Types of Analog I/O Problems

Analog I/O problems in PLCs typically appear after installation or maintenance. These issues often fall into three major categories: constant offset error, percentage offset error, and unstable readings. Each has distinct symptoms and root causes.

Constant Offset Error

A constant offset error occurs when the measured signal consistently deviates from the expected value by a fixed amount. This often includes a zero error, where a zero input voltage does not register as zero.

One of the most common causes is improper grounding. When an analog input shares its ground path with another current-carrying device, a voltage drop appears along the shared conductor. The resulting potential difference introduces a false signal.

To avoid this, use two-wire analog inputs and extend both wires directly to the signal source. Implement single-point grounding, ensuring the negative wire is grounded at only one location. Be cautious: many analog sensors have an internally grounded negative terminal. Grounding both ends can create a ground loop, leading to continuous offset errors.

Author insight: Ground loops remain one of the most frequent and overlooked causes of analog signal distortion in factory automation environments.

Percentage Offset Error (Gain Error)

Percentage offset errors, also known as gain errors, appear when the measured signal differs by a constant proportional factor rather than a fixed amount. These can result from inaccurate scaling within the analog input, sensor output inconsistencies, or loading effects between the sensor’s output resistance and the PLC input impedance.

Additionally, errors in voltage divider circuits used for signal scaling can produce similar effects if resistor tolerances are mismatched. Always verify resistor ratios using precision components and recheck calibration under operating conditions.

Unstable or Noisy Analog Readings

Unstable readings, often called signal noise, occur when measured values fluctuate despite stable source voltages. This issue is primarily caused by electromagnetic interference (EMI) or electrostatic coupling between analog cables and nearby power conductors.

To minimize noise, use twisted-pair shielded cables for analog signal transmission. The twisted configuration ensures equal exposure to interference, allowing the differential input amplifier to cancel common-mode noise. Ground the cable shield at only one end to prevent circulating currents.

Avoid routing analog signal cables near AC power lines, motor leads, or transformers. If interference persists, route sensitive cables through steel conduit for magnetic shielding. These practices align with industry standards from manufacturers like Siemens, Rockwell Automation, and ABB.

Author insight: A well-designed cable layout often reduces analog signal errors more effectively than software filtering.

Practical Troubleshooting Approach

When troubleshooting analog I/O issues, adopt a step-by-step diagnostic process:

-

Verify input scaling and raw register values using PLC monitoring tools.

-

Measure actual field voltage with a calibrated multimeter.

-

Inspect grounding and shielding arrangements.

-

Check for mechanical or environmental noise sources nearby.

-

Confirm sensor output specifications and PLC input impedance.

Document each step for traceability and future reference. A structured approach helps isolate root causes faster and improves long-term reliability.

Application Scenarios and Solutions

Case 1: Flow Transmitter Displays Incorrect Values

-

Recheck loop grounding and verify 4–20 mA calibration.

-

Measure loop resistance and power supply stability.

Case 2: Temperature Sensor Output Fluctuates

-

Inspect thermocouple wiring for EMI exposure.

-

Route cables away from high-current sources.

-

Replace cable with twisted-pair shielded type.

Case 3: Analog Input Reads Zero Despite Signal Presence

-

Check module configuration and channel mapping.

-

Inspect sensor power supply and common return line.

-

Verify that no ground loop exists between devices.

Conclusion

Reliable analog I/O performance is essential for maintaining accuracy in industrial automation and process control systems. Understanding the root causes of offset errors, gain mismatches, and electrical noise allows engineers to diagnose and resolve issues efficiently. As automation technology advances, adherence to good grounding, wiring, and shielding practices remains fundamental.

Accurate analog signal management not only ensures stable PLC operation but also improves overall system efficiency, safety, and product quality.