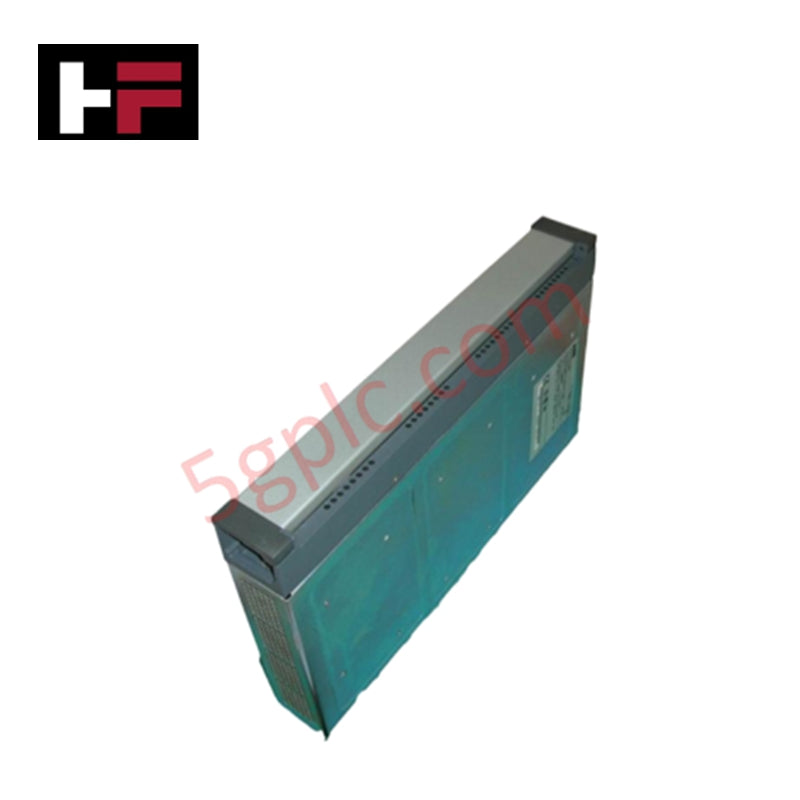

Product Details

Overview

The ABB PM863K02 (3BSE088382R1) is a redundant processor unit from the AC 800M controller series, designed for advanced process and factory automation systems requiring high availability. Powered by the MPC866 microprocessor, this unit provides deterministic control, fast response times, and fault-tolerant operation. It is ideal for distributed control architectures where system uptime and synchronization accuracy are critical.

Core Specifications

-

Processor Type: MPC866 microprocessor

-

Redundant Operation: Supported, with maximum switch-over time of 10 ms

-

Controller Application Capacity:

-

32 independent applications

-

64 programs per application

-

128 control diagrams per application

-

32 simultaneous tasks

-

Cycle Times: Up to 32 distinct cycle configurations; minimum application cycle time 10 ms

-

Firmware Storage: 18 MB Flash PROM for system firmware

-

Built-In Battery: 3.6 V lithium backup for memory and real-time clock

-

Clock Synchronization: 1 ms accuracy across AC 800M controllers via CNCP protocol

Electrical Characteristics

-

Power Supply: 24 V DC (operating range 19.2–30 V DC)

-

Power Consumption: 210 mA typical, 360 mA maximum

-

Power Dissipation: 5.1 W typical, 8.6 W maximum

-

Redundant Power Input Monitoring: Supported

Communication and Networking

-

Ethernet Channels: Two RJ-45 ports (IEEE 802.3, 10 Mbit/s)

-

Supported Network Protocols: MMS (Manufacturing Message Service) and IAC (Inter Application Communication)

-

Recommended Network Backbone: 100 Mbit/s switched Ethernet

-

OPC Event Handling:

-

Up to 3000 queued events per OPC client

-

Transmission rate: 36–86 events/sec or 113–143 data messages/sec

-

CEX Bus Communication: Supports up to 12 communication modules

-

CEX Bus Supply Current: Max 2.4 A

I/O and System Integration

-

I/O Clusters (Non-Redundant CPU): 1 electrical + 7 optical

-

I/O Clusters (Redundant CPU): 7 optical only

-

Maximum I/O Capacity: 96 I/O modules (single CPU) or 84 modules (redundant configuration)

-

ModuleBus Scan Rate: Adjustable from 0 to 100 ms depending on system load

-

Electrical ModuleBus Supply:

-

24 V: max 1.0 A

-

5 V: max 1.5 A

Interfaces

-

RS-232C Ports: Two ports (one general, one for service tool)

-

COM3 (Non-redundant use): RS-232C, 75–19,200 baud, RJ-45, non-isolated, full RTS/CTS

-

COM4 (Non-redundant use): RS-232C, 9,600 baud, RJ-45, optically isolated, no RTS/CTS

-

Real-Time Clock Stability: 100 ppm (approx. one hour drift per year)

Application Scenarios

The PM863K02 is optimized for:

-

Mission-critical process automation systems with redundancy requirements

-

Continuous operation in power, oil and gas, and chemical plants

-

Distributed control configurations requiring precise synchronization and deterministic performance

FAQ

Q: What distinguishes the PM863K02 from the PM862K01?

A: The PM863K02 features a larger 18 MB firmware memory and is optimized for redundant configurations, while the PM862K01 offers similar processing power but less firmware storage.

Q: Can the PM863K02 operate as a standalone controller?

A: Yes, it can function in non-redundant mode; however, it is primarily designed for use in fault-tolerant configurations.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.