Smart Elevator Automation Systems: Driving Lifecycle Efficiency in Industrial and Commercial Buildings

- 〡

- 〡 by WUPAMBO

How Smart Automation Redefines Elevator Operations

Industrial automation principles are increasingly applied to vertical transportation. Smart elevator systems leverage data-driven control, predictive maintenance, and traffic optimization to reduce operational costs and improve reliability. Building owners no longer view elevators solely as passenger amenities; instead, these systems are critical assets whose efficiency directly affects building economics and tenant satisfaction.

Optimizing Elevator Traffic Through Advanced Control Algorithms

Destination control systems transform elevator traffic management. Instead of passengers pressing standard up or down buttons, they input their target floors, allowing the system to group riders efficiently. This reduces unnecessary stops and increases handling capacity without adding physical shafts.

Moreover, predictive dispatch algorithms analyze historical usage and peak-hour patterns to position elevators proactively. Morning lobby surges, lunch breaks, and evening departures are managed automatically, reducing wait times and enhancing throughput. In multi-bank elevator configurations, smart control coordinates car assignments across zones, balancing load and preventing bottlenecks. For industrial and commercial facility managers, this means more effective space utilization and deferred infrastructure upgrades.

Predictive Maintenance: Extending Component Life and Reducing Downtime

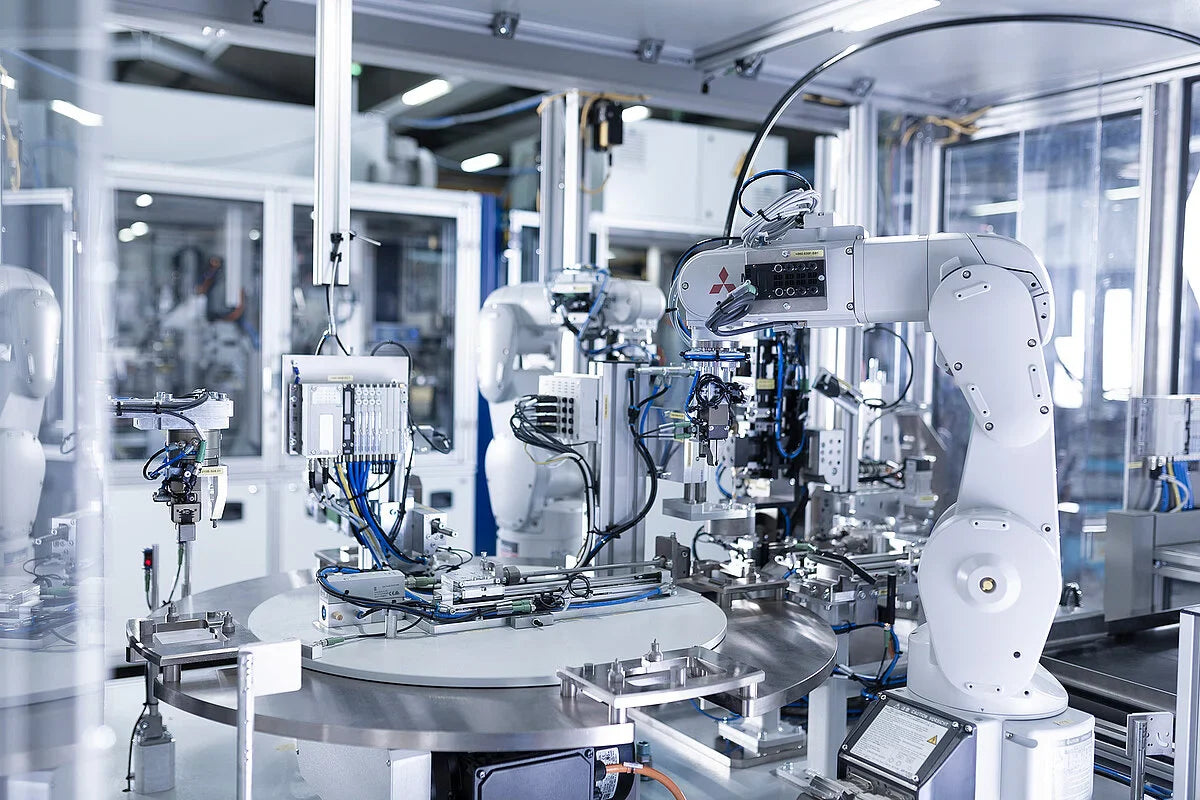

Predictive maintenance lies at the core of smart elevator value. Sensor networks monitor key components—motors, door mechanisms, hoist ropes, and control systems—in real time. Data on vibrations, temperature, and usage cycles feed cloud-based machine learning models to anticipate failures before they occur.

This proactive approach allows technicians to schedule maintenance during planned windows, minimizing emergency repairs. It extends component life and reduces unnecessary part replacements. In practice, predictive maintenance mitigates tenant disruption, safety risks, and potential service-level agreement penalties. For facility operators, the result is a measurable improvement in uptime and reliability over the elevator’s 20- to 30-year lifespan.

Reducing Maintenance Costs Through Remote Monitoring and Diagnostics

Smart elevator systems streamline maintenance operations. Condition-based servicing ensures parts are replaced only when needed, avoiding unnecessary labor and inventory costs. Remote diagnostics allow minor issues to be resolved without on-site visits, while automated fault reporting provides clear guidance for technicians.

These capabilities optimize workforce deployment and enable a single service team to manage multiple installations efficiently. In addition, detailed digital logs simplify compliance checks and support performance-based service contracts. Over decades of operation, these efficiencies translate into significant reductions in total cost of ownership.

Lifecycle Economics Outweigh Installation Costs

Although smart elevator automation may increase upfront costs by 10–15%, the long-term savings are substantial. Energy consumption can drop by 20–40%, maintenance costs by 15–25%, and uptime can improve by several percentage points. Return on investment often occurs within three to seven years, with benefits compounding across the remaining asset life.

Downtime has tangible consequences: reduced usable space, tenant dissatisfaction, lease concessions, and operational disruptions. For mixed-use buildings, elevator reliability also affects retail foot traffic and guest experiences. Therefore, lifecycle performance is a stronger adoption driver than initial cost.

Regulatory Compliance and Energy Efficiency Support

Elevator safety codes require consistent inspections, load testing, and documentation. Smart automation systems automatically log operational and maintenance data, simplifying compliance and minimizing administrative effort. Continuous monitoring also enables real-time verification of emergency systems and door operation.

Additionally, energy efficiency regulations and building certification programs like LEED or BREEAM reward elevators that implement regenerative braking, energy monitoring, and optimized motor operation. Automation thus supports both regulatory adherence and sustainability goals.

Author Insights: Future Trends in Industrial Elevator Automation

In my observation, smart elevator systems are evolving toward fully integrated building automation. They will increasingly communicate with HVAC, lighting, and security systems, creating a holistic approach to operational efficiency. Facility managers who embrace predictive, data-driven control gain a competitive advantage, reducing costs while enhancing occupant satisfaction. Industrial automation concepts—traditionally applied in PLC and DCS environments—are now central to vertical transportation management.

Application Scenarios

-

Commercial Towers: Optimize peak-hour traffic, reduce downtime, and extend component life.

-

Mixed-Use Developments: Balance passenger flow between residential, retail, and office zones.

-

Industrial Complexes: Integrate elevator performance data with overall facility automation systems for predictive maintenance planning.