ABB Extends Distributed Control Systems to Advance Industrial Automation Modernization

- 〡

- 〡 by WUPAMBO

ABB is redefining the landscape of industrial automation with its new initiative, Automation Extended, a major evolution of its distributed control system (DCS) technology. The company aims to help industries modernize operations efficiently—without sacrificing reliability or uptime.

Balancing Modernization and Operational Continuity

Many industries face a critical challenge: integrating new automation technologies while maintaining continuous production. According to Peter Terwiesch, President of ABB’s Process Automation business area, this balance remains one of the biggest barriers to digital transformation in complex industrial environments.

Terwiesch noted that customers operating large, interconnected systems—such as refineries, chemical plants, and utilities—cannot afford extended downtime. Therefore, ABB’s focus is on enabling modernization without disruption, ensuring that digital upgrades enhance, rather than interrupt, plant performance.

Introducing ABB Automation Extended

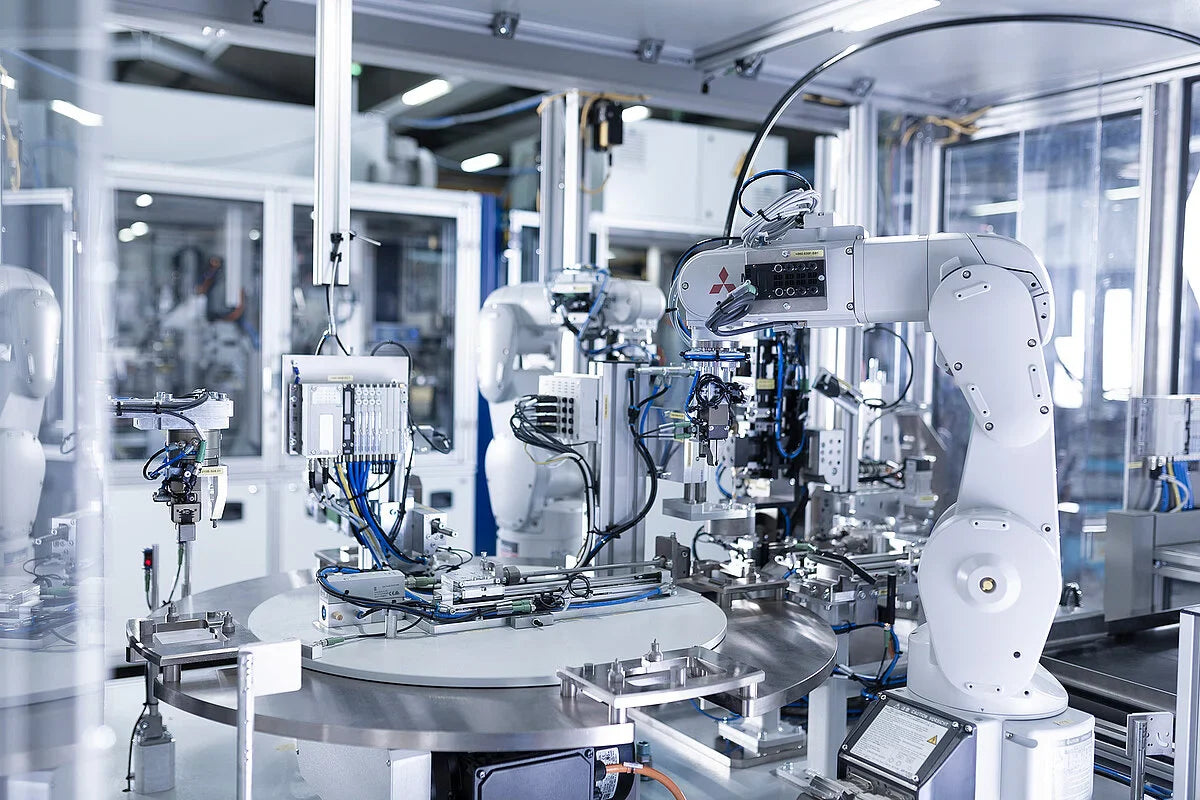

ABB’s Automation Extended initiative introduces a scalable, software-defined control architecture that expands the capabilities of traditional DCS platforms. It provides advanced connectivity, analytics, and artificial intelligence (AI) tools while maintaining the reliability of proven control systems.

This next-generation platform combines two complementary layers:

-

A control environment, which manages real-time operations and process stability.

-

A digital environment, which applies AI, edge intelligence, and data analytics for predictive optimization.

These components function independently but remain tightly integrated, providing what ABB calls a “unified automation ecosystem.”

A Strategic Evolution of DCS Technology

Rather than replacing existing systems, Automation Extended represents a strategic evolution of ABB’s control architecture. It allows industrial operators to integrate new digital capabilities incrementally, leveraging existing infrastructure and minimizing risk.

ABB explained that the new approach will be delivered through software updates to its current portfolio of process automation systems. This ensures that industries such as energy, chemicals, and mining can adopt innovations without major overhauls or extended shutdowns.

Integrating AI and IoT for Smarter Control Systems

A key advantage of Automation Extended lies in its integration of AI-driven analytics and Internet of Things (IoT) connectivity. These technologies enable operators to analyze real-time data from distributed assets, predict potential issues, and make informed operational decisions faster.

By shifting toward a software-defined control model, ABB enables a more flexible and data-centric approach to process automation. The system’s edge computing capabilities ensure that time-critical decisions are made locally, improving both responsiveness and resilience.

Cybersecurity and Lifecycle Management

As industrial systems become increasingly connected, cybersecurity and lifecycle management are critical considerations. ABB emphasized that Automation Extended incorporates robust cybersecurity frameworks designed to safeguard data integrity and operational reliability.

In addition, the unified platform simplifies lifecycle management by providing a centralized environment for configuration, updates, and performance optimization. This approach helps reduce maintenance costs and extend the lifespan of existing automation assets.

ABB’s Broader Industrial Vision

ABB’s Automation Extended reflects a broader trend across the factory automation sector—moving toward open, flexible, and interoperable control ecosystems. Competitors such as Siemens, Emerson, and Honeywell are pursuing similar strategies, integrating AI, analytics, and cloud platforms into their control architectures.

However, ABB’s long-standing expertise in DCS technology gives it a unique advantage. Its installed base in industries like oil and gas, power generation, and manufacturing positions it to deliver upgrades that are both technologically advanced and operationally proven.

Expert Commentary: A Step Toward Autonomous Operations

From an industry perspective, Automation Extended represents a clear step toward autonomous industrial systems. By combining deterministic control with adaptive digital intelligence, ABB is bridging the gap between traditional DCS and future self-optimizing plants.

The company’s modular design philosophy also aligns with the Industry 4.0 movement, which prioritizes data-driven decision-making, interoperability, and continuous improvement. For operators, the key benefit lies in achieving greater operational resilience without costly shutdowns.

Application Scenario: Continuous Modernization in a Refinery

Consider a large petrochemical refinery operating around the clock. A complete control system replacement could cause millions in production losses. By adopting ABB’s Automation Extended, the plant can gradually upgrade digital layers—such as predictive analytics and remote diagnostics—while keeping the existing control infrastructure active. This approach ensures continuous modernization with minimal disruption.

Conclusion: A Future-Ready Approach to Industrial Automation

ABB’s Automation Extended marks a significant milestone in the evolution of industrial control systems. It offers a pragmatic path toward modernization—one that blends the reliability of traditional DCS with the intelligence of digital technologies.

As industries face growing pressure to increase efficiency, safety, and sustainability, ABB’s hybrid strategy provides a proven framework for achieving digital transformation without downtime.