ABB to Deliver Advanced Shore Power Systems at Rotterdam Port

- 〡

- 〡 by WUPAMBO

ABB Wins Major Rotterdam Shore Power Contract

ABB has been selected to design, construct, and maintain shore power systems across three deep-sea container terminals in the Port of Rotterdam. The project, part of the Port of Rotterdam’s decarbonization strategy, includes APM Terminals Maasvlakte II, Hutchison Ports ECT Delta, and Hutchison Ports ECT Euromax.

Scope of the Shore Power Installation

The project will equip 8 kilometers of quay with 35 connection points for container vessels. Each terminal will have its own dedicated shore power infrastructure, organized under separate construction and maintenance contracts. ABB’s role covers detailed engineering, construction, and long-term operational support. Construction is scheduled to start in the second half of 2027, with the terminals fully operational by mid-2028.

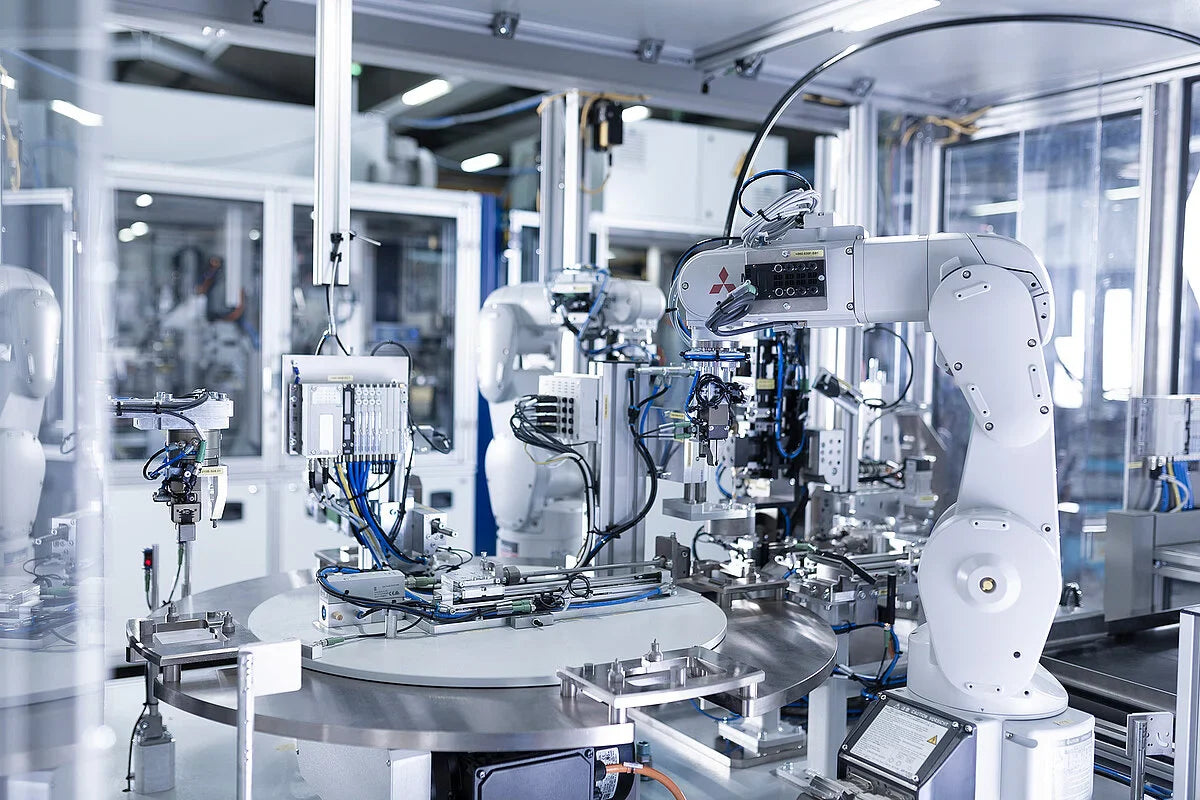

Technical Highlights and Industrial Automation Integration

ABB’s solution integrates industrial automation, PLC control systems, and DCS technology to manage the shore-to-ship power transfer efficiently. The installations include high, medium, and low-voltage cables, fiberglass conduits, and converter stations. The system supports 10/100 MVA capacity, making it the world’s largest shore power setup currently. These advanced control systems enable safe, reliable, and automated power delivery to vessels while reducing operational downtime.

Environmental Impact and Energy Transition

Shore power allows ships to connect directly to the port grid, eliminating the need to run diesel generators while docked. This significantly reduces noise, particulate emissions, nitrogen oxides, and CO₂. ABB’s solution aligns with the EU’s emission reduction goals and Rotterdam’s target to have most sea-going vessels connected to shore power by 2030.

ABB Expertise and Industry Leadership

Rune Braastad, President of ABB’s Marine & Ports division, emphasized that the project highlights ABB’s expertise in factory automation and industrial control systems. “We deliver end-to-end solutions from concept through commissioning, ensuring minimal disruption and maximum operational reliability,” he said. ABB combines proven automation technologies with hands-on marine industry experience, guaranteeing system robustness and compliance with international standards.

Redundant Networking and System Reliability

The shore power design incorporates dual-port redundancy and real-time monitoring, enabling high availability and safety. Terminals can use PLC-based control systems to manage power distribution dynamically, supporting complex topologies and ensuring uninterrupted operation. This approach reflects industry best practices in industrial automation, particularly for high-stakes port operations.

Author Insight: Implications for Industrial Automation

This project demonstrates how industrial automation technologies extend beyond traditional manufacturing into port and marine applications. By integrating PLCs, DCS, and automated monitoring systems, ABB sets a benchmark for future energy-efficient and digitally controlled port operations. Industrial automation engineers can apply similar methodologies to optimize energy management, predictive maintenance, and process safety in other sectors.

Applications and Use Cases

-

Container terminal operations requiring automated energy management

-

Integration of DCS and PLC systems for shore-to-ship power control

-

Industrial decarbonization initiatives in maritime and logistics sectors

-

Energy-efficient retrofitting of port and factory infrastructures

- Posted in:

- control systems

- DCS

- PLC

- port electrification

- shore power systems