Maximizing Industrial Efficiency with Advanced Programmable Logic Controllers (PLCs)

- 〡

- 〡 by WUPAMBO

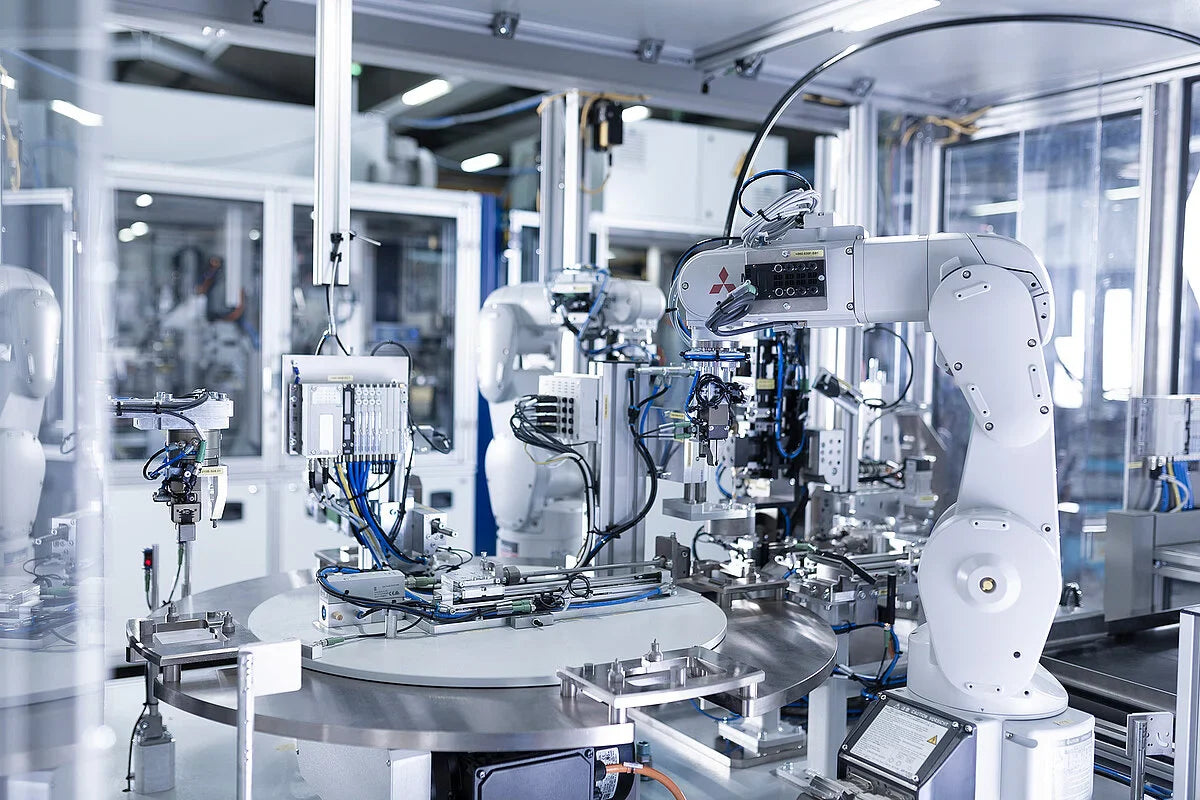

Programmable Logic Controllers (PLCs) serve as the fundamental brain of modern factory automation. These ruggedized industrial computers manage complex processes with precision and speed. In today’s data-driven manufacturing landscape, selecting the right controller is essential for maintaining a competitive edge.

The Role of Ruggedized Hardware in Industrial Automation

Modern PLCs must thrive in harsh environments where standard computers would fail. These controllers feature compact, durable housings that resist heat, vibration, and electrical noise. Consequently, they ensure continuous uptime for critical infrastructure. Reliability is the most vital factor when integrating a new controller into an existing system.

Streamlining Connectivity with PROFINET Integration

Seamless communication remains a cornerstone of effective control systems. Most high-performance PLCs now utilize PROFINET capability to facilitate high-speed data exchange. This industrial Ethernet standard allows for real-time diagnostics and hardware synchronization. Moreover, it simplifies the integration of sensors and actuators across the factory floor.

Scaling Solutions from Micro Applications to Complex Architectures

Scalability allows manufacturers to grow without replacing their entire infrastructure. Small-scale operations often begin with micro controllers to manage simple, repetitive tasks. However, larger enterprises require modular architectures to handle thousands of I/O points. A versatile PLC lineup ensures that your control system expands alongside your production needs.

Prioritizing Safety Control in Modern Manufacturing

Safety is no longer an afterthought in industrial deployments. Dedicated safety PLCs monitor critical parameters to prevent equipment damage and personnel injury. These systems often meet strict international standards like SIL 3 or PLe. Integrating safety and logic into a single platform reduces wiring complexity and lowers total cost of ownership.

Expert Insight: The Shift Toward Edge-Enabled PLCs

From my perspective, the industry is moving beyond simple logic execution. We are seeing a significant trend where PLCs act as "Edge" devices. They do not just control motors; they collect and pre-process data for cloud analytics. I believe that engineers who prioritize controllers with built-in cybersecurity and MQTT support will future-proof their operations most effectively.

Real-World Application Scenarios

-

Automotive Assembly Lines: High-speed PLCs coordinate robotic arms and conveyor systems via PROFINET to ensure millisecond precision.

-

Water Treatment Plants: Modular controllers manage distributed pump stations and chemical dosing, providing remote monitoring over long distances.

-

Food and Beverage Packaging: Micro PLCs handle high-speed sorting and labeling tasks while maintaining strict hygiene and safety protocols.

- Posted in:

- Automation Technology

- Edge Computing.

- Industrial Automation

- Industrial Computing

- Modular PLC

- PLC

- PROFINET

- Safety Integrated