Secure 2026 Operations: Moore Automation Launches Strategic Year-End Stock-Up for Bently Nevada Systems

- 〡

- 〡 by WUPAMBO

Meeting Industrial Automation Challenges in Year-End Shutdowns

Industrial manufacturers in oil, gas, power generation, and petrochemicals face dual challenges each December. They must execute planned shutdowns while preparing for uninterrupted operations in the coming year. Moore Automation, a trusted supplier of PLC and DCS components, addresses this need with its "Reliability First" Christmas Campaign.

Strategic Inventory for Legacy Control Systems

Unlike typical holiday promotions, this initiative focuses on factory automation reliability. Starting December 1, Moore Automation opens its reserve of Bently Nevada inventory. This includes rare and discontinued modules that are often difficult to source. As a result, plant managers can secure critical assets before 2026 begins.

Preventative Maintenance as a Priority

December is a crucial window for preventative maintenance in industrial automation. A failure in vibration monitoring systems can cause catastrophic downtime. Moore Automation ensures immediate access to replacement parts, reducing risks linked to long OEM lead times. This proactive approach strengthens machinery protection and operational continuity.

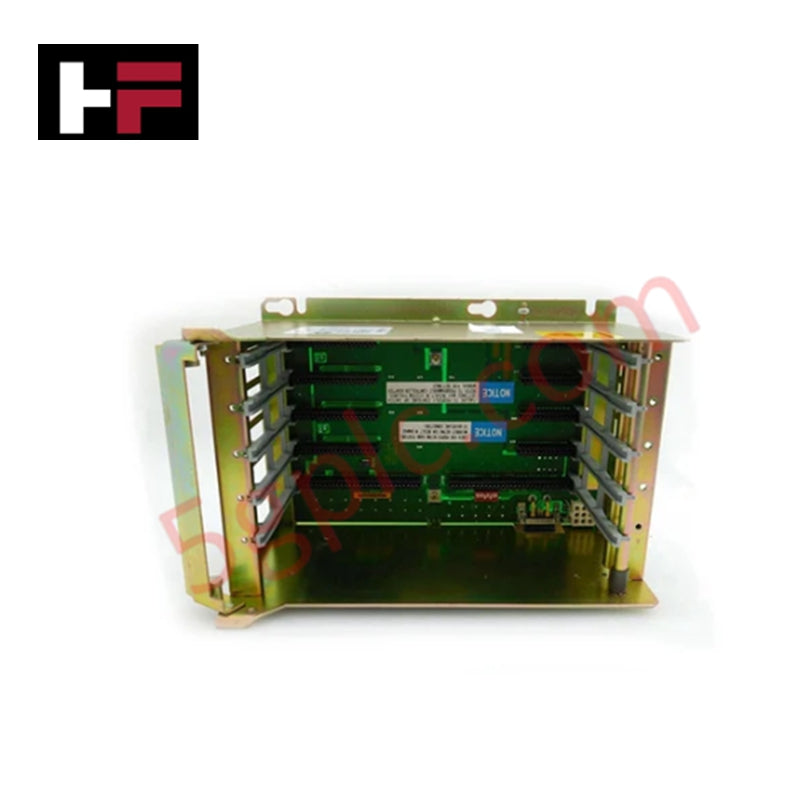

Spotlight on Bently Nevada Machinery Protection Systems

Moore Automation highlights essential components for Bently Nevada 3500 and 3300 systems, widely recognized for API 670 compliance.

-

3500/22M Transient Data Interface (TDI): The communication core of the 3500 rack, enabling continuous waveform data collection.

-

3300 XL Proximitor Systems: Designed for extreme environments, these sensors deliver precise shaft vibration and position monitoring.

-

3300/45 Position Monitor: Supporting legacy systems, this module extends infrastructure life where upgrades are not feasible.

Moore Automation’s Competitive Advantage

Moore Automation offers more than seasonal pricing. Its service standards include:

-

Immediate Dispatch: Over 20,000 parts in stock minimize logistics delays.

-

Quality Assurance: Every unit undergoes inspection and carries a 1-year warranty.

-

Obsolete Part Expertise: The company specializes in sourcing discontinued modules, offering cost-effective alternatives to full system upgrades.

Industry Commentary and Insights

The campaign reflects a broader trend in industrial automation: balancing modernization with legacy system support. Many plants still rely on older control systems, and sourcing parts remains a challenge. Moore Automation’s strategy demonstrates how suppliers can bridge this gap. In my view, this approach strengthens trust in automation supply chains and reduces unnecessary capital expenditure.

Application Scenarios and Solutions

-

Oil & Gas: Ensuring turbine vibration monitoring during seasonal shutdowns.

-

Power Generation: Maintaining continuous diagnostic capabilities in steam turbines.

-

Petrochemical Plants: Extending the life of legacy 3300 systems without costly upgrades. These scenarios highlight how strategic stocking supports operational resilience across industries.