ABB Enhances Industrial Automation and Electrification at Boliden’s Aitik Copper Mine

- 〡

- 〡 by WUPAMBO

ABB Upgrades Electrification Systems for Safer Mining Operations

ABB has implemented advanced electrification and automation solutions at Boliden’s Aitik copper mine in northern Sweden. This upgrade strengthens tailings management, water recycling, and operational monitoring, ensuring safe and efficient expansion of Europe’s largest open-pit copper mine. In addition, the modernization allows Boliden to scale production while maintaining strict environmental and safety standards.

Responding to Growing Copper Demand with Industrial Automation

Global copper demand is rising steadily, with the International Energy Agency forecasting a 22% increase by 2035. In response, Boliden focuses on sustainable mining and tailings management aligned with the Global Industry Standard on Tailings Management (GISTM). ABB’s electrification and control systems, designed for sub-arctic conditions, provide reliable power and real-time monitoring of water flow and dam stability.

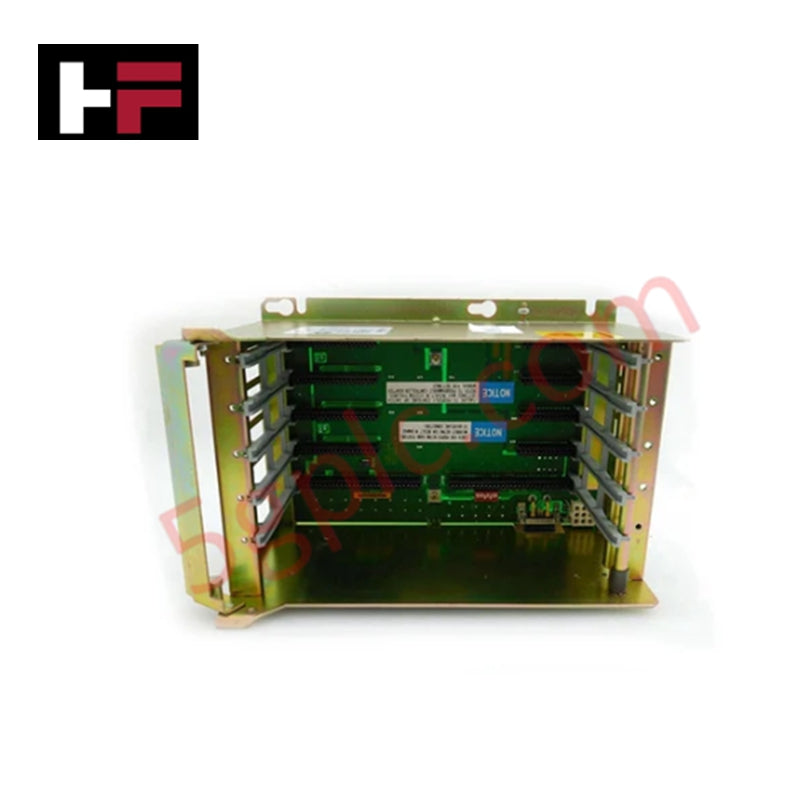

Modular Electrical Solutions for Reliable Power and Control

ABB delivered modular electrical houses, medium- and low-voltage switchgear, transformers, and variable speed drives for pumping stations. These components integrate seamlessly with the ABB Ability™ System 800xA® distributed control system (DCS), offering centralized visibility of energy usage, predictive maintenance insights, and system diagnostics. This industrial automation setup ensures consistent tailings dam performance under varying operational conditions.

Benefits of PLC and DCS Integration in Mining

The combination of programmable logic controllers (PLCs) and DCS platforms enables Boliden to optimize mining operations efficiently. Operators can monitor energy consumption, detect anomalies, and implement automated control strategies. As a result, ABB’s technology not only increases productivity but also reduces environmental risks, demonstrating the value of advanced control systems in large-scale mining projects.

Expert Insights: The Future of Mining Automation

According to Björn Jonsson, ABB’s Global Business Line Manager for Mining & Materials, “Modular electrification and automation allow rapid deployment without compromising safety.” In practice, this project highlights a growing trend in industrial automation: leveraging digitalized control systems to balance operational efficiency with sustainability goals. Industrial engineers should consider similar integrated solutions when scaling production under regulatory constraints.

Boliden’s Perspective on Operational Resilience

Peter Nystedt, Boliden Project Office Manager, emphasized that completing the project on time and within budget reinforces the importance of dependable industrial automation in critical infrastructure. Mining companies can achieve operational resilience by combining robust electrification with predictive control strategies, minimizing downtime and enhancing process reliability.

Conclusion: Industrial Automation as a Strategic Advantage

ABB’s deployment at Aitik demonstrates how industrial automation, PLCs, DCS, and integrated control systems can improve efficiency, safety, and sustainability. For mining operators, adopting such technologies is no longer optional—it is a strategic necessity to meet growing demand and comply with international standards.

Application Scenarios

-

Tailings Management: Real-time monitoring of dam stability using DCS and sensor networks.

-

Water Recycling Systems: Variable speed drives optimize pumping efficiency in harsh climates.

-

Energy Optimization: Centralized control enables predictive maintenance and reduced energy costs.

-

Factory and Plant Automation: Modular electrification supports scalable industrial operations.