Maximizing Industrial Project Success Through Advanced Automation Process Functionalities

- 〡

- 〡 by WUPAMBO

The success of any industrial process plant depends on the safety and performance of its control systems. These systems reflect the core functionalities implemented during the design phase. To achieve high performance, system vendors and instrumentation and control (I&C) specialists must maintain clear communication. They ensure that technical data aligns with the project’s specific requirements. Consequently, plant operators gain the ability to navigate system facilities and respond to real-time process changes effectively.

Essential Core Facilities of Modern Control Systems

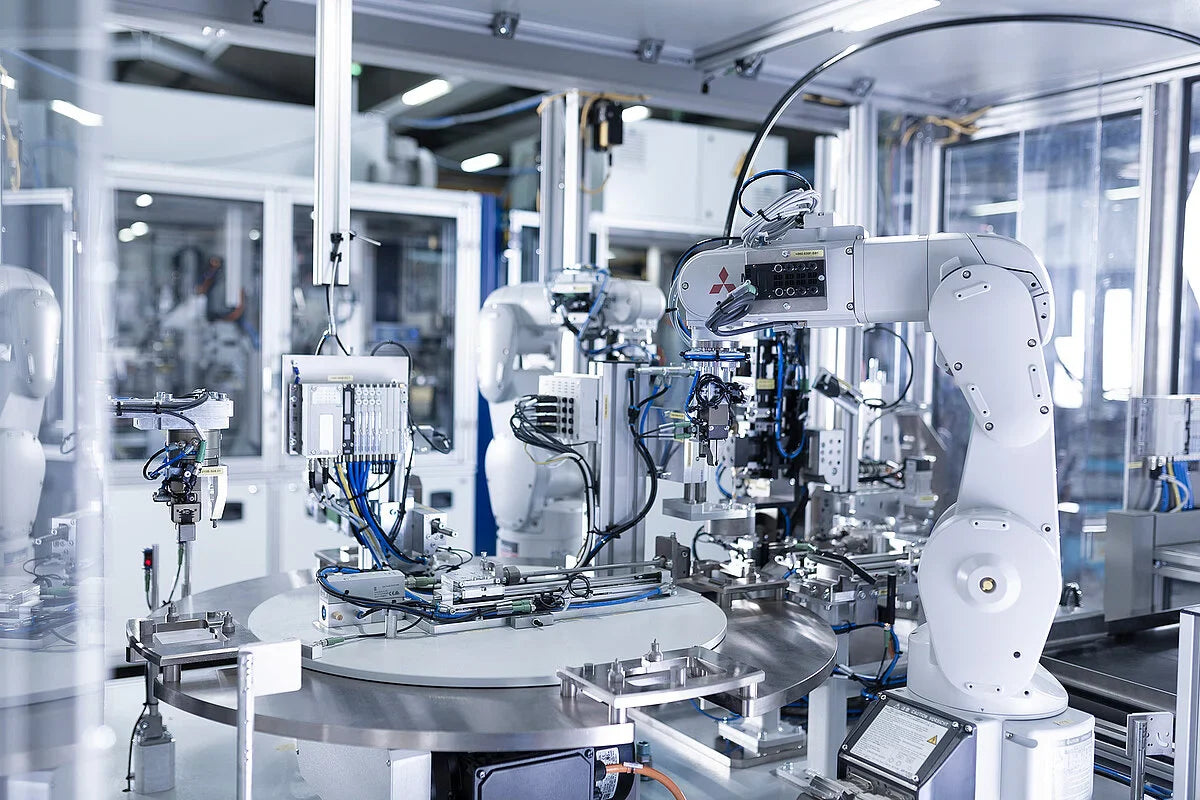

Modern factory automation relies on diverse functional facilities to manage complex industrial tasks. These include hardware I/O conditioning, alarm management, and high-speed networking. Furthermore, systems must handle time synchronization, historian data storage, and change management. Programmable control systems, such as Distributed Control Systems (DCS) and Safety Instrumented Systems (SIS), execute these functions. By integrating these facilities, plants achieve high levels of reliability.

Implementing the IEC 61131-3 Programming Standard

The IEC 61131-3 standard serves as the universal foundation for industrial programming. Almost every major vendor, including ABB, Yokogawa, and Schneider Electric, follows this framework. It defines five distinct programming languages to suit different applications. For example, Ladder Diagram (LD) is ideal for discrete logic. Meanwhile, Structured Text (ST) excels in complex mathematical calculations. Moreover, using a standardized environment makes engineering vendor-independent.

Strategic Selection of Programming Languages

Engineers select specific languages based on the desired control outcome. Sequential Function Charts (SFC) are perfect for batch processing and step-by-step sequences. In contrast, Function Block Diagrams (FBD) provide a visual way to manage continuous analog loops. As a result, specialists can choose the most efficient tool for either sequence or analog control. This flexibility reduces engineering time and minimizes the risk of logical errors during the development phase.

Translating Design Logic into Safety Instrumented Systems

During the detailed engineering phase, design teams create interlock logic diagrams based on ISA 5.2 standards. System vendors then translate these into functional code, typically using FBD or Ladder logic. High-integrity systems, like HIMA or Emerson DeltaV SIS, rely on this clear mapping. When the system logic mirrors the design symbols, troubleshooting becomes much faster. Operators can easily identify faults through color-coded signal status changes on their displays.

Optimizing HMI and Data Integration for Plant Overview

Successful automation requires more than just logic; it requires intuitive visualization. Effective coordination between I&C teams and vendors produces comprehensive HMI graphic displays. These displays offer an overview of ESD (Emergency Shut Down) logic and plant-wide conditions. Therefore, operators can monitor package system functionalities from a single centralized location. This holistic approach ensures that data flows seamlessly across all communication links.

Expert Insight: Managing Hidden System Constraints

From my perspective, engineers often overlook "hidden" technical constraints like CPU load and execution cycle times. In large-scale DCS projects, a high CPU load can cause dangerous delays in control response. Therefore, it is critical to balance functional complexity with hardware capabilities. I recommend performing early-stage load simulations to avoid bottlenecks. Furthermore, keeping logic simple improves long-term maintainability for the end-user.

Application Scenario: High-Pressure Steam Turbine Protection

In power generation, protecting a steam turbine requires precise logic functionality.

-

The Problem: The turbine requires an emergency trip if vibration levels exceed a specific threshold for more than two seconds.

-

The Solution: Using FBD, engineers implement a "time-delay" block connected to an "OR" gate receiving multiple sensor inputs.

-

The Implementation: This logic is integrated into a Safety Instrumented System (SIS) that triggers a mechanical trip valve.

-

The Benefit: By following IEC 61131-3, the logic is transparent and easily verified during the annual Safety Integrity Level (SIL) audit.

- Posted in:

- DCS

- factory automation

- Industrial Automation

- PLC systems