Rethinking Poultry Ventilation with Industrial Automation and VSDs

- 〡

- 〡 by WUPAMBO

Optimizing poultry ventilation is essential for animal welfare, energy efficiency, and farm profitability. ABB’s latest research demonstrates how variable speed drives (VSDs), integrated with PLC and control systems, modernize farm ventilation, reduce energy use, and improve operational reliability.

Challenges in Poultry Ventilation

Poultry farms often face uneven airflow, equipment strain, and operational inefficiencies. Traditional fans operate at fixed speeds, limiting control over environmental conditions. These challenges affect animal health, increase energy costs, and raise insurance risks. Therefore, modern automation solutions are critical to ensure consistent airflow and safe conditions across different farm types.

How VSDs Improve Efficiency and ROI

ABB’s whitepaper shows VSDs offer measurable benefits: 12–24 months ROI for layer farms, 18–30 months for broilers, up to 50–55% integration with solar power, and 70% airflow continuity in failsafe mode. Intelligent fan control adjusts speeds dynamically, reducing energy consumption while maintaining stable temperatures and air quality. Predictive maintenance alerts further prevent unplanned downtime, enhancing farm reliability.

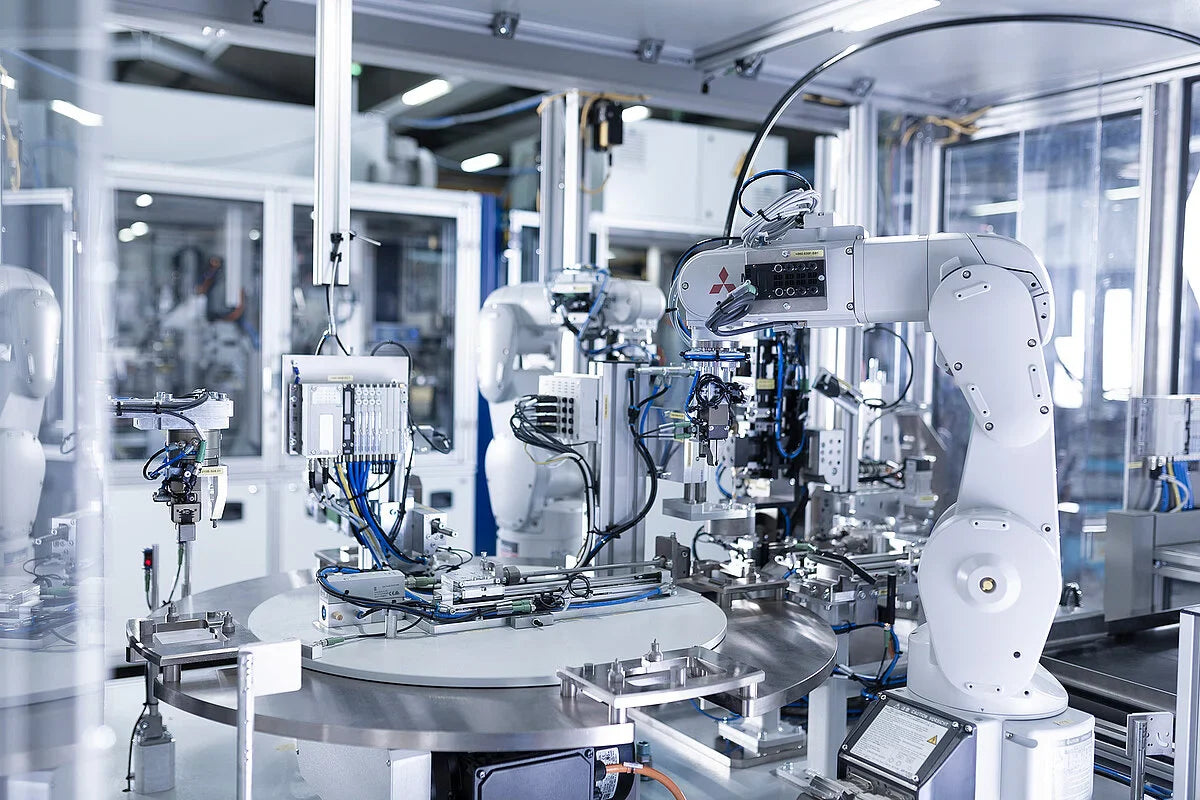

Integration with PLC and Control Systems

VSDs work seamlessly with PLCs, SCADA, and DCS platforms to automate ventilation. Operators can monitor real-time airflow, adjust settings remotely, and generate data for reporting. This integration reduces manual interventions, cuts fuel consumption from on-site inspections, and improves overall operational governance.

Enhancing Animal Welfare and Farm Governance

Stable ventilation directly impacts flock health. Controlled airflow and temperature reduce stress, prevent disease, and support consistent growth and egg production. Automated monitoring also strengthens governance by recording operational metrics, ensuring regulatory compliance, and reducing human error.

Renewable Energy and Sustainability Benefits

ABB’s ACS280 and ACS380 drives allow farms to integrate solar PV systems, reducing grid dependency and lowering emissions. Automation ensures devices turn off when idle, conserving energy and improving environmental performance. As a result, farms achieve both cost savings and ESG-aligned sustainability goals.

Industry Insights and Recommendations

Farmers often hesitate to adopt VSDs due to perceived complexity or upfront cost. However, ABB’s field data confirms reliable performance and rapid ROI across multi-site operations. Combining VSDs with PLC-controlled automation provides a scalable, energy-efficient, and animal-friendly solution, making ventilation modernization a strategic investment for poultry producers.

Application Example: Multi-Site Layer Farm

A multi-site egg farm installed ABB ACS380 drives integrated with PLCs and solar PV. Real-time monitoring enabled predictive maintenance, stabilized airflow, and cut energy costs by 40%. Operational data validated ROI within 18 months and improved overall flock health, demonstrating the practical benefits of automated ventilation.

- Posted in:

- animal welfare

- energy efficiency

- factory automation

- PLC

- poultry ventilation

- predictive maintenance

- SCADA integration

- VSD