Top Industrial Automation Companies Transforming Smart Warehouses Worldwide

- 〡

- 〡 by WUPAMBO

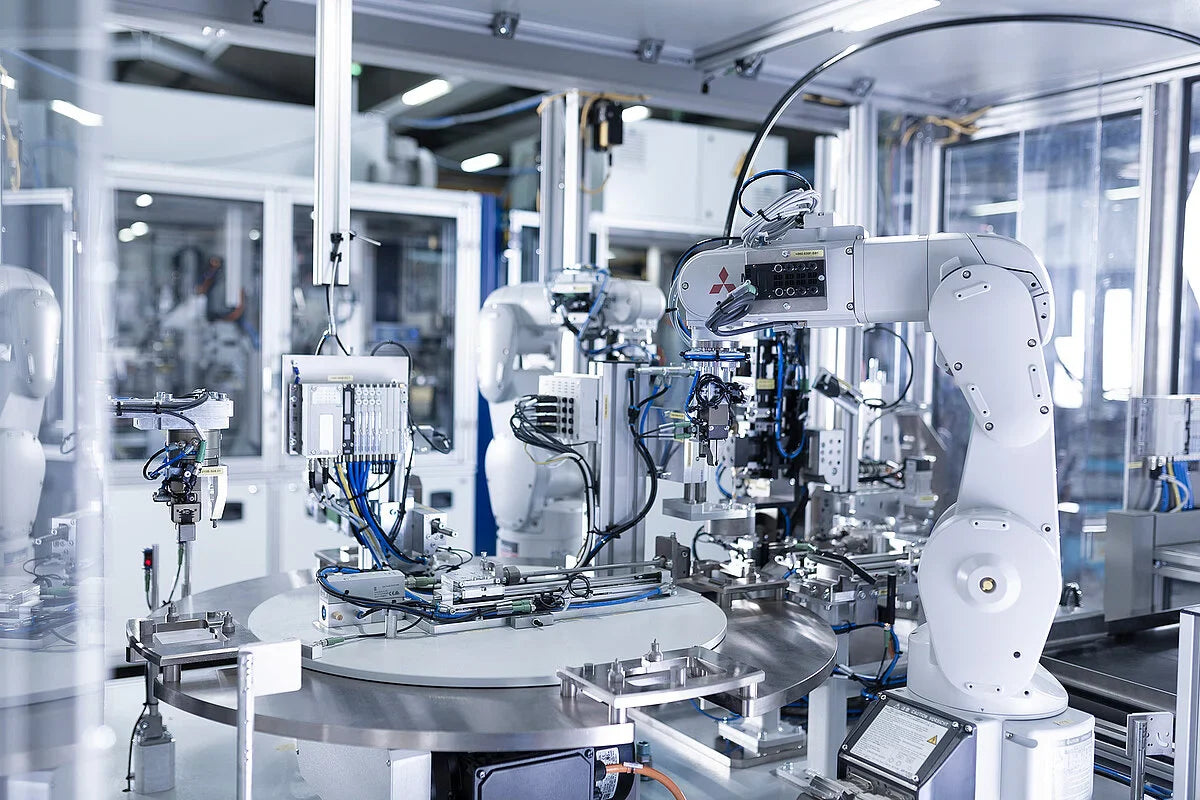

Warehouse operations are evolving rapidly due to growing e-commerce demand, labor shortages, and the need for real-time visibility. Industrial automation technologies, including robotics, PLCs, DCS, and intelligent software, are now critical for creating efficient, scalable, and reliable warehouses. In this article, we explore seven leading companies that are shaping the future of smart warehouses.

Addverb: End-to-End Warehouse Automation Solutions

Addverb is a global leader in warehouse automation, offering complete solutions for material movement, picking, storage, and returns. The company develops both hardware and software in-house, ensuring seamless integration with warehouse management systems (WMS). Addverb’s solutions serve e-commerce, retail, manufacturing, and third-party logistics sectors, improving throughput, safety, and operational predictability.

Author Insight: Addverb stands out because of its ability to upgrade existing warehouses while planning for future scalability.

Novus Hi-Tech: Streamlining Material Flow

Novus Hi-Tech specializes in industrial automation and intralogistics solutions. Their offerings include automated conveyors, sorting technologies, and warehouse software integration. By reducing manual intervention, Novus Hi-Tech enhances visibility, accuracy, and efficiency throughout the warehouse.

Author Insight: Companies with complex supply chains benefit significantly from Novus Hi-Tech’s solutions, as they optimize both throughput and material handling accuracy.

Caja Robotics: Robotic Goods-to-Person Fulfillment

Caja Robotics focuses on autonomous goods-to-person robots that boost picking efficiency and storage density. These robots integrate with software platforms to streamline order fulfillment and adapt to fluctuating SKU volumes.

Author Insight: Flexible robotics, like those from Caja, are essential for warehouses facing rapid order variability and seasonal demand spikes.

Armstrong Ltd: Engineered Material Handling Solutions

Armstrong Ltd provides conveyors, automated storage systems, and handling equipment for manufacturing and logistics warehouses. Their systems integrate with WMS platforms to ensure reliable, safe, and efficient operations.

Author Insight: Armstrong’s solutions emphasize stability and operational control, making them ideal for high-throughput industrial environments.

Maveneer: Intelligent Fulfillment Optimization

Maveneer combines automated machinery with smart software to enhance inventory management, material movement, and order fulfillment. Their solutions deliver real-time insights and help warehouses reduce errors and delays.

Author Insight: Real-time visibility is a game-changer, particularly for multi-site distribution networks where coordination is key.

GeekPlus: Autonomous Mobile Robot Systems

GeekPlus provides autonomous mobile robots for picking, transporting, and sorting, reducing reliance on human operators. Their systems are widely used in e-commerce, retail, and logistics to accelerate order processing.

Author Insight: Mobile robotics not only improve efficiency but also support scalable warehouse expansion without major infrastructure changes.

Dematic: Comprehensive Automation Solutions

Dematic is a global leader in intralogistics, offering conveyors, sortation systems, automated storage, and software solutions. Their systems handle large-scale distribution and manufacturing warehouses requiring high throughput and sustainability.

Author Insight: Dematic’s experience with high-volume warehouses ensures consistent performance and reliable integration with existing DCS and WMS platforms.

Why These Companies Are Critical for Smart Warehousing

Smart warehouses rely on the integration of robotics, industrial automation, PLCs, and control systems. These companies provide the tools to optimize material flow, enhance accuracy, and maintain real-time operational visibility. However, a robust WMS remains central to fully utilizing automated processes.

Author Insight: Businesses must carefully select automation partners to ensure scalability, reliability, and compatibility with existing industrial control systems.

Conclusion: Embracing Industrial Automation for Future-Ready Warehouses

Warehouse automation is no longer optional; it is essential for competitiveness. Companies like Addverb, Dematic, and GeekPlus lead the way by combining robotics, smart software, and industrial control technologies. By integrating these solutions with PLCs, DCS, and warehouse management systems, businesses can achieve predictable throughput, operational safety, and scalable operations.

Author Insight: As supply chains grow more complex, selecting the right automation partner is critical for long-term operational efficiency and flexibility.

Practical Applications and Solution Scenarios

-

E-commerce Fulfillment: Using autonomous robots for high-density picking

-

Cold Storage Warehouses: Integrating conveyors and automated storage for precise temperature control

-

Manufacturing Support: Real-time material transport with robotic and PLC-controlled systems

-

Smart Grid Inventory: Optimizing multi-site warehouse networks with intelligent software and DCS integration