What Is Loop Checking in Industrial Automation?

- 〡

- 〡 by WUPAMBO

Understanding the Concept of Loop Checking

Loop checking is a pre-commissioning procedure used in industrial automation systems to verify the complete signal path between field instruments and control systems such as PLC (Programmable Logic Controllers) or DCS (Distributed Control Systems).

In simple terms, it ensures that every sensor, transmitter, actuator, and control logic element works together as intended — from the physical field device to the operator interface (HMI). This process is crucial before plant startup, as it validates both signal integrity and control functionality.

Purpose and Importance of Loop Checking

The main objective of loop checking is to confirm that all control loops are properly installed, calibrated, and integrated. By doing so, engineers can detect issues like wiring errors, incorrect scaling, communication faults, or misconfigured control parameters before system commissioning.

A successful loop check guarantees that:

-

Field devices are correctly wired and powered.

-

Input and output signals correspond to real process values.

-

Control algorithms in PLC or DCS respond correctly to signal changes.

-

HMIs accurately reflect process conditions and alarm states.

In other words, loop checking bridges design intent with real-world operation, ensuring plant safety and performance.

Key Components of a Control Loop

A standard control loop in factory automation consists of:

-

Field devices – sensors, transmitters, and actuators.

-

Signal transmission – via 4–20 mA current loops or digital communication protocols (e.g., Profibus, Modbus).

-

Controller – typically a PLC or DCS managing logic and control algorithms.

-

HMI – displaying process data, alarms, and trends to operators.

Each element must function in harmony for stable process control. Therefore, during loop checking, engineers systematically test every component along this chain.

Step-by-Step Loop Checking Procedure

1. Preparing Loop Documentation

Before testing, engineers collect all loop drawings, tag numbers, calibration sheets, and wiring diagrams. Each loop is documented with essential data such as range, zero and span settings, alarm limits, and signal routing.

2. Grouping Loops for Efficiency

Loops are organized by system, location, or process area. Grouping by location allows technicians to move logically through equipment with minimal downtime.

3. Field Verification

Technicians inspect each field device for correct installation, calibration, and process connection. They verify proper electrical terminations, grounding, and signal polarity.

4. Signal Simulation and Monitoring

Using calibration tools or handheld communicators, the technician simulates input signals (commonly 4 mA, 12 mA, and 20 mA). The control room engineer observes the corresponding signal on the DCS or PLC interface and checks alarm activation, scaling accuracy, and HMI response.

5. Control Function Testing

When testing control loops, the system is briefly placed in auto mode. The engineer verifies that control outputs (e.g., valve positions or motor speeds) respond proportionally to input variations.

6. Recording and Reporting Results

Results are documented for each loop, including readings, deviations, and any identified issues. Loops passing the test are marked “complete.” If discrepancies are found, a deficiency report or “kick-back form” is issued for corrective action.

Common Issues Found During Loop Checks

Loop checking often reveals installation or configuration errors such as:

-

Reversed polarity in signal wiring.

-

Incorrect analog range scaling.

-

Faulty transmitter calibration.

-

Loose terminal connections.

-

Wrong I/O mapping in PLC or DCS configuration.

Identifying these early prevents costly downtime during plant startup.

Industry Best Practices

To maintain consistency and safety, loop checks should follow established industry standards such as ISA-5.4 (Instrumentation Loop Diagrams) and ISA-62382 (Procedures for Loop Checks). Documentation and traceability are essential — every action must be logged and verified by authorized personnel.

Moreover, digital commissioning tools are now helping automate parts of the loop check process, reducing manual errors and improving efficiency.

Expert Commentary: The Shift Toward Digital Loop Checking

In modern factories, digital field networks and smart transmitters have changed traditional loop-checking methods. Instead of purely analog 4–20 mA signals, today’s systems use HART, Profibus, or Foundation Fieldbus protocols.

This evolution allows automated loop verification, where software tools can remotely simulate and monitor signal performance, saving time and improving accuracy. However, manual verification remains important for confirming physical installation integrity — a step that digital tools cannot replace entirely.

Real-World Application Example

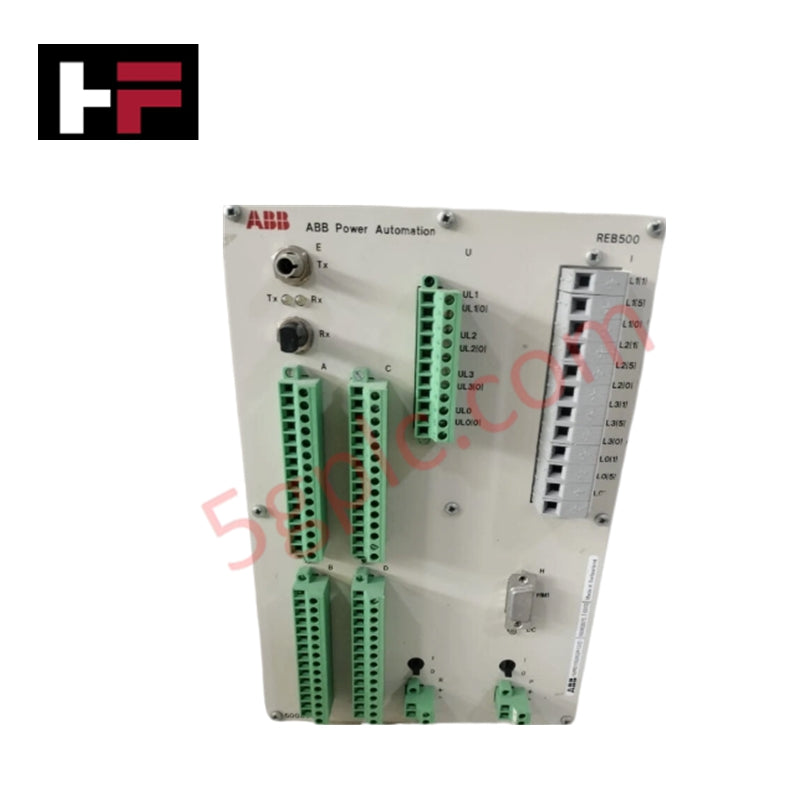

During a refinery modernization project, engineers performed loop checks across 1,200 control loops connected to an ABB DCS system. By grouping loops geographically and using handheld communicators for HART-enabled transmitters, they reduced total commissioning time by 30%. Early identification of wiring errors and misconfigured ranges prevented potential shutdowns during startup.

Conclusion

Loop checking is not just a procedural step — it’s a quality assurance process that validates the foundation of every industrial control system. A properly executed loop check ensures seamless communication between field devices and controllers, reduces startup risks, and enhances operational safety.

As automation systems continue to evolve, the integration of digital diagnostics and smart commissioning tools will make loop checking faster and more precise — but the fundamental principle remains the same: verify every signal, confirm every response, and document every result.