Understanding Reading Mismatches Between Field Instruments and Control Room Systems

- 〡

- 〡 by WUPAMBO

Common Issue in Industrial Automation

In industrial automation, engineers often encounter discrepancies between field transmitter readings and the values displayed on control room systems such as PLCs or DCS. This issue, though common, can have multiple root causes. Understanding these causes is essential for maintaining accurate process control and ensuring reliable system performance.

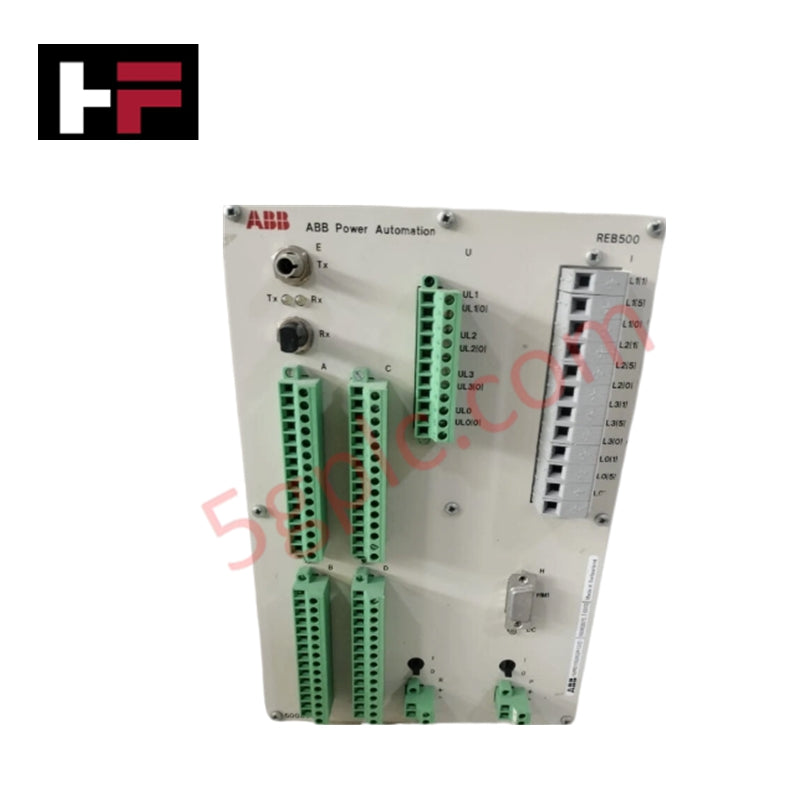

Configuration Mismatch Between Transmitter and DCS

One of the most frequent causes of reading mismatches is improper range configuration.

For example, if a temperature transmitter is calibrated for 0–250 °C but the DCS range is set to 0–200 °C, the control room display will show an incorrect value compared to the field display.

To prevent this, always verify that both the transmitter and the DCS or PLC analog input card share identical LRV (Lower Range Value) and URV (Upper Range Value) settings. Consistent configuration across devices ensures accurate scaling and eliminates the most common source of mismatch.

When Configuration Is Correct but Readings Still Differ

Sometimes, even when both configurations match perfectly, discrepancies persist. This often occurs due to a 4–20 mA loop current drop—a subtle yet impactful issue in analog signal transmission.

Though the 4–20 mA standard theoretically maintains constant current throughout the loop, practical conditions such as high cable resistance or poor terminations can cause small but measurable drops.

Typical Causes of 4–20 mA Loop Current Drop

Common contributors to signal drops include:

-

High resistance in main or branch cables

-

Ground loops and poor shielding

-

Improper calibration of transmitter output or DCS input cards

-

Low-resolution or uncalibrated analog input modules

-

Loose or corroded terminals

-

Electrical noise or induced EMF from nearby equipment

Even a small drop—say 0.01 mA—can create noticeable deviations in displayed process values, especially in systems with large measurement ranges.

Measuring and Verifying Loop Current Drops

To identify whether current drop is the source of the problem, engineers can follow these steps:

-

Measure the loop current using a calibrated multimeter connected in series.

-

Compare readings between the multimeter and the transmitter’s internal HART output.

-

Evaluate the difference: if the transmitter’s HART shows 6.00 mA but the multimeter shows 5.99 mA, a loop loss of 0.01 mA is present.

The HART display remains accurate because it reads digital data directly from the transmitter CPU, bypassing the analog signal path. The DCS, however, receives the analog current, making it vulnerable to small losses in the loop.

Example 1: Low-Range Application

Consider a pressure transmitter with a range of 0–10 kg/cm².

If the transmitter shows 1.25 kg/cm² in the field (corresponding to 6 mA), but the control room reads 1.24375 kg/cm² (corresponding to 5.99 mA), the error is 0.00625 kg/cm² or 0.06%.

In most low-range applications, such minor discrepancies are acceptable. The system’s accuracy class and display resolution determine whether such differences are meaningful.

Example 2: High-Range Application

Now, consider a flare flow transmitter with a span of 0–150,000 kg/hr.

A 0.01 mA drop (6.00 mA vs. 5.99 mA) causes a 93.75 kg/hr deviation between field and control room readings.

Though the percentage error remains only 0.06%, the absolute difference is significant. For high-span transmitters, even small signal drops can affect mass balance calculations and performance monitoring.

Why Loop Current Drops Matter

While a 0.01 mA drop may seem trivial, it can lead to process inefficiencies or misinterpretation in critical applications such as custody transfer, energy measurement, or emission monitoring. Regular inspection of analog loops is therefore essential to maintain system reliability.

Moreover, as plants adopt digital communication standards (e.g., Foundation Fieldbus, Profibus PA, or Ethernet-based systems), such issues are being minimized—but many legacy systems still rely on analog loops, making this knowledge vital for instrumentation engineers.

Engineer’s Insight

Based on field experience, loop integrity should be verified during every preventive maintenance cycle. Using precision calibration tools, ensuring proper grounding, and replacing aging cables can drastically reduce mismatch issues.

Furthermore, modern smart transmitters with diagnostic features can alert users to potential current loop degradation, improving predictive maintenance strategies in factory automation and process control systems.

Practical Solutions and Application Scenarios

-

Regular Calibration: Verify both transmitter and DCS scaling annually.

-

Cable Management: Use twisted shielded pairs and maintain proper grounding.

-

Digital Verification: Use HART or Fieldbus diagnostics to detect discrepancies early.

-

Critical Applications: Consider digital communication protocols where signal loss is eliminated.

Conclusion

Reading mismatches between field transmitters and control room systems arise mainly from configuration errors or loop current drops. Even minimal current variations can lead to noticeable process value deviations, especially in wide-range transmitters. By maintaining accurate calibration, proper loop integrity, and periodic verification, engineers can ensure precise and reliable measurement across the entire control system network.

- Posted in:

- 4-20mA signal

- control systems

- DCS

- factory automation

- instrumentation engineering

- PLC

- process control