Understanding the Difference Between PLC and HMI in Industrial Automation

- 〡

- 〡 by WUPAMBO

Introduction to Industrial Automation Devices

In industrial automation, PLCs and HMIs are essential components for controlling and monitoring processes. PLCs handle machine logic, while HMIs allow operators to visualize and interact with systems. Understanding their roles is crucial for designing efficient factory automation solutions.

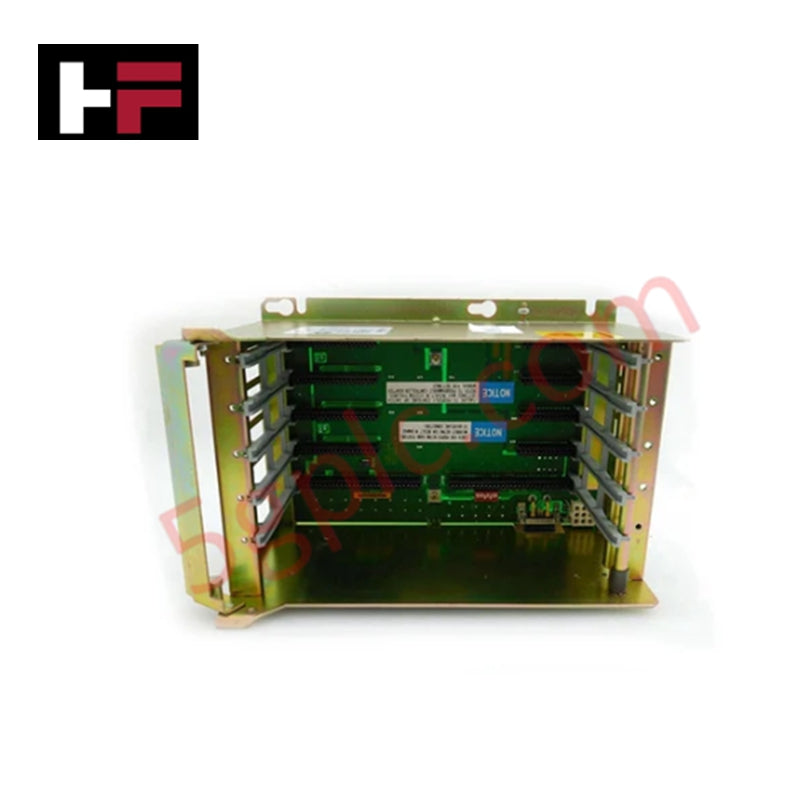

What is a PLC? The Brain of Control Systems

A Programmable Logic Controller (PLC) executes logic to control machines and processes. It receives inputs from sensors or buttons, processes logic according to its program, and generates outputs to actuators like motors or valves. PLCs integrate both hardware and software, connecting with I/O modules and industrial networks to manage complex operations. Knowledge of programming and system configuration is key to working effectively with PLCs.

What is an HMI? The Operator’s Interface

A Human-Machine Interface (HMI) provides a graphical view of a PLC’s operations. Operators can monitor input and output statuses, view trends, and adjust system parameters through screens designed with symbols, colors, and icons. HMIs simplify interaction with complex control systems, improving visibility, decision-making, and operational safety in industrial environments.

Key Differences Between PLC and HMI

PLCs process logic, while HMIs display logic visually. Operators configure and monitor parameters via HMIs, whereas PLCs handle programming and hardware configuration. Advanced HMIs offer audit trails, reports, and trend analysis, while PLCs focus on I/O management, network setup, and system libraries. In short, PLCs act as the brain, and HMIs serve as the eyes of automation systems.

How PLC and HMI Work Together in Factory Automation

Integrating PLCs with HMIs ensures seamless industrial automation. PLCs perform real-time control, and HMIs provide operators with actionable insights. This combination reduces downtime, improves process efficiency, and supports predictive maintenance. Moreover, it aligns with modern industrial standards, enhancing safety and operational reliability.

Expert Insights: Choosing the Right Automation Setup

Selecting the appropriate PLC and HMI depends on process complexity, scalability, and user interface requirements. For instance, large-scale production lines benefit from high-performance PLCs paired with multi-screen HMIs, allowing comprehensive monitoring. Industrial engineers should also consider trends like DCS integration, cloud connectivity, and advanced analytics to future-proof automation systems.

Application Scenarios for PLC and HMI

-

Process Monitoring: Track machine inputs and outputs in real time.

-

Factory Automation: Use PLCs and HMIs to optimize assembly lines and production workflows.

-

Predictive Maintenance: Detect anomalies early through HMI visualization of PLC data.

-

Energy Management: Monitor and control energy usage efficiently with integrated control systems.