Overcoming the Speed-Precision Tradeoff: SinceVision’s Industrial Automation Innovations in 2026

- 〡

- 〡 by WUPAMBO

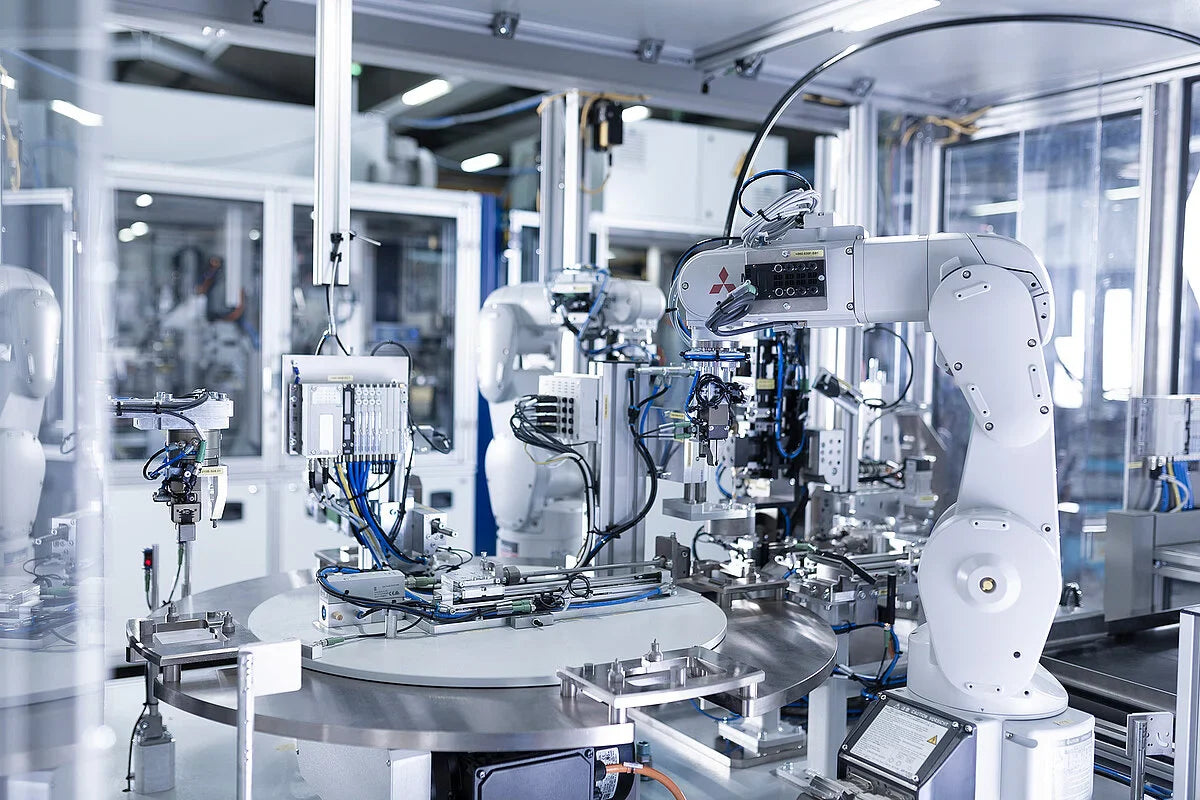

Redefining High-End Factory Automation

In modern industrial automation, manufacturers often face a difficult tradeoff: increase production speed or maintain measurement accuracy. This challenge is particularly acute in sectors like electric vehicles, semiconductors, and high-end consumer electronics. As global Tier-1 brands push production limits, the speed-precision paradox has become a critical bottleneck. Shenzhen SinceVision Technology Co. Ltd. addresses this issue through extensive R&D and patented innovation. With over 100 invention patents and a team of 200+ engineers, SinceVision delivers 2026 solutions that optimize both throughput and accuracy.

Global Adoption: Trusted by 10,000 Industry Leaders

SinceVision’s industrial automation solutions are deployed by over 10,000 companies worldwide. Its client portfolio includes Apple, Tesla, Samsung, LG, CATL, BYD, and Foxconn. With more than 100,000 sensors installed globally, SinceVision has earned a reputation as the “eyes” of smart factories, enabling real-time process control and defect prevention.

3D Laser Profilers: Uniting Speed and Accuracy

SinceVision’s 3D sensors are engineered to deliver sub-micron precision without slowing production lines.

-

SR8000: Achieves 67 kHz sampling, capturing high-speed production with zero data loss.

-

SR7000 & SR9000: Offer 3,200 and 6,400 points along the X-axis, respectively, ensuring ultra-dense point clouds for detailed measurements.

-

Integrated 3D Profilers (SRI): Designed for tight spaces, they save over 50% installation area while providing linear laser resolution suitable for complex industrial shapes.

These technologies are particularly valuable for PLC- and DCS-controlled production lines, where real-time feedback is crucial.

Industrial Sensors: High-Frequency Detection for Diverse Materials

Beyond 3D profiling, SinceVision provides a range of sensors to address challenging materials and high-speed processes:

-

Laser Displacement Sensors: 590 kHz sampling captures fast-moving objects with stable readings. One controller supports up to four sensors for simplified integration.

-

Spectral Confocal Sensors: Handle mirrored, transparent, and irregular surfaces while maintaining high precision at a cost-effective price. Two sensors per controller enhance scalability.

-

Full-Spectrum Color Sensors: Deliver rapid RS485 communication (200 μs) for precise color identification in complex production lines.

-

Through-Beam Edge Sensors: Ideal for web edge control, offering 0.4% F.S. linearity and EtherCAT support for multiple device connections.

These sensors enhance factory automation, ensuring accurate monitoring and control across multiple industrial applications.

Scientific Cameras: Capturing Data Beyond Human Vision

SinceVision also advances imaging solutions for research and aerospace applications:

-

High-Speed Cameras: The 5K Series provides 21 MP at 1000 fps; the 4K Series reaches 8 MP at 2000 fps. Up to 24 TB on-camera storage prevents data bottlenecks.

-

sCMOS Cameras: With 95% quantum efficiency at 560 nm and 2048×2048 resolution, these cameras deliver high-quality microscopy images across 190–1100 nm spectral range.

Such high-performance imaging supports both industrial inspection and scientific research, demonstrating SinceVision’s versatile expertise in industrial automation.

Industry Impact: Serving Diverse High-Growth Sectors

SinceVision’s solutions cater to multiple industries, ensuring tailored automation and inspection capabilities:

-

Energy & New Technology: Lithium batteries, photovoltaic, semiconductor manufacturing.

-

Mobility & Aviation: Automotive, aerospace, and shipping applications.

-

Infrastructure & Research: Civil engineering, bionics, and hydrodynamics.

-

Consumer & Health: Electronics, pharmaceuticals, food, and packaging.

By addressing sector-specific challenges, SinceVision enhances productivity, quality, and reliability across complex factory automation systems.

Commitment to Global Standards

SinceVision actively participates in international organizations, including the European Machine Vision Association (EMVA), A3 Association for Advancing Automation, China Machine Vision Industry Union (CMVU), and Japan Industrial Imaging Association (JIIA).

This engagement ensures products meet high benchmarks for reliability, safety, and seamless integration with PLCs, DCS systems, and other industrial control platforms.

Expert Insight: The Future of Speed and Precision

The industrial automation landscape increasingly demands high-speed, high-precision solutions. SinceVision demonstrates that strategic innovation and patent-driven R&D can eliminate traditional tradeoffs. Manufacturers integrating these technologies benefit from faster production cycles without sacrificing accuracy, ultimately reducing costs and defects.

Application Scenarios

-

EV Battery Manufacturing: High-speed 3D profiling ensures uniform cell thickness.

-

Semiconductor Fabrication: Laser displacement sensors detect wafer micro-defects.

-

Automotive Assembly: Edge sensors guide robotic precision welding and assembly.

-

Research Labs: High-speed cameras capture material stress tests in real-time.