Honeywell Air Purifiers and Industrial Automation: Smarter Control Systems for Cleaner Environments

- 〡

- 〡 by WUPAMBO

Growing Demand for Air Quality Solutions in Factory Automation

Industrial automation increasingly integrates environmental control systems to ensure safe and efficient operations. Honeywell’s recent price reduction on air purifiers highlights how automation technologies extend beyond production lines into workplace health. As a result, companies now evaluate air purification as part of their broader factory automation strategies.

Importance of Air Purifiers in Industrial Settings

Air purifiers play a critical role in industrial automation environments where dust, smoke, and chemical fumes are common. Unlike traditional ventilation, advanced purifiers with multi-stage filtration systems actively remove PM2.5 particles and VOCs. Therefore, they complement PLC and DCS-based control systems by maintaining stable air quality parameters.

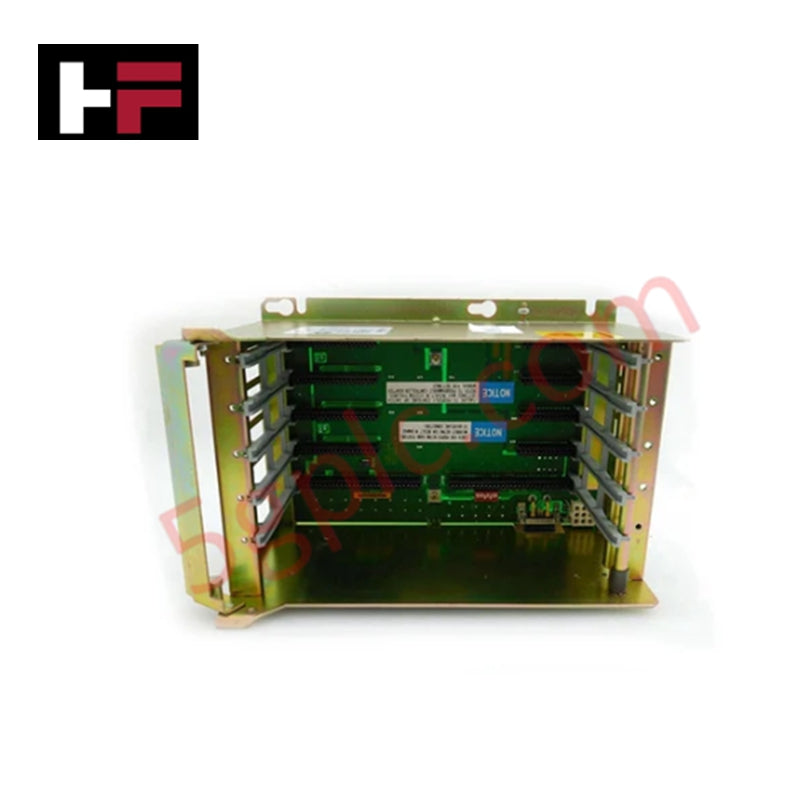

Advanced Features Supporting Control Systems Integration

Honeywell air purifiers feature real-time air quality indicators and automated modes. These functions align with industrial automation principles, where sensors feed data into control systems for continuous monitoring. Moreover, filter lifespan indicators reduce maintenance downtime, supporting lean manufacturing and predictive maintenance strategies.

Key Honeywell Models for Factory and Office Use

-

Air Touch V5: Four-stage purification, CADR suitable for large spaces, ideal for production offices.

-

Air Touch V2: Compact design, quiet operation, effective for medium-sized control rooms.

-

Air Touch V1: Budget-friendly, three-stage filtration, suitable for small workstations. These models demonstrate how industrial automation extends into workplace comfort, ensuring operators remain productive in controlled environments.

Portable Solutions for Vehicles and On-the-Go Applications

Honeywell Move Pure series offers compact purifiers for vehicles, useful for field engineers and mobile staff. The Move Pure 4 integrates HEPA and antibacterial layers, while the Move Pure 3 adds formaldehyde removal. In addition, USB ports support device charging, reflecting how automation solutions increasingly combine convenience with safety.

Energy Efficiency and Maintenance in Factory Automation

Energy-efficient designs reduce operational costs, a key factor in industrial automation. Sleep and auto modes optimize consumption, while tool-less filter replacement minimizes downtime. As a result, these purifiers align with sustainability goals and ISO standards for energy management.

Author’s Commentary on Industry Trends

The integration of air purification into industrial automation reflects a broader trend: automation is no longer limited to production efficiency but extends to worker health. Companies adopting PLC and DCS systems should also consider environmental monitoring as part of their control strategies. In my view, this convergence strengthens both productivity and compliance with occupational safety regulations.

Application Scenarios and Solutions

-

Factory Automation: Purifiers integrated with PLC systems to monitor air quality in assembly lines.

-

Control Rooms: Compact models ensure operators remain focused without exposure to pollutants.

-

Mobile Engineers: Vehicle purifiers maintain clean air during site visits. These scenarios illustrate how Honeywell’s solutions enhance industrial automation environments by combining health, safety, and efficiency.