ABB Expands Industrial Automation and Electrification for Boliden’s Aitik Copper Mine

- 〡

- 〡 by WUPAMBO

Meeting Rising Copper Demand with Smarter Automation

Global copper demand is expected to rise by 22 percent by 2035. Therefore, mining companies must adopt sustainable practices. Boliden’s Aitik mine in Sweden demonstrates how industrial automation and electrification can support safe, efficient growth while meeting international standards.

Tailings Dam Safety Through Advanced Control Systems

Boliden required reliable systems to manage water flows and dam behavior. ABB delivered modular electrification and control systems designed for sub‑arctic conditions. These solutions ensure compliance with the Global Industry Standard on Tailings Management (GISTM) while enhancing operational safety.

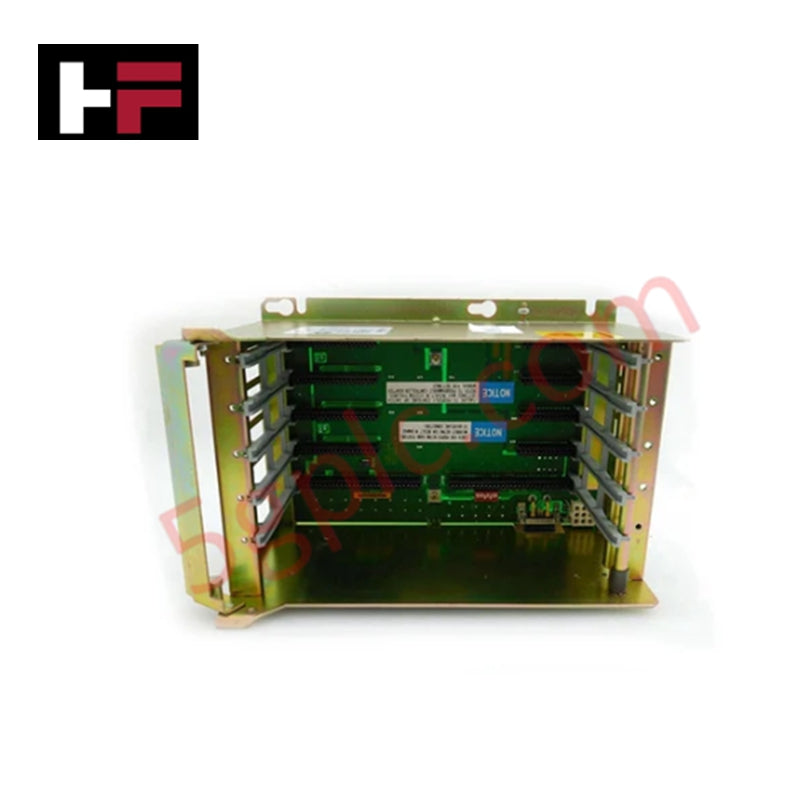

Modular Electrification for Rapid Deployment

ABB’s modular e‑houses and switchgear allowed fast installation with minimal downtime. In addition, transformers and variable speed drives optimized pumping operations. This modular approach highlights how factory automation can accelerate project timelines without compromising quality.

Distributed Control Systems for Real-Time Oversight

The ABB Ability™ System 800xA® DCS provides centralized supervision of energy flows. Moreover, predictive maintenance alerts and real‑time diagnostics reduce risks of downtime. Such control systems are critical for modern mining operations where reliability and safety are paramount.

Sustainable Mining Practices and Long-Term Resilience

Boliden integrates zero‑harm tailings management with reclamation strategies. Once mining stages finish, land restoration ensures environmental responsibility. As a result, the Aitik mine aligns with global sustainability goals while maintaining production efficiency.

Industry Expertise and Authoritative Standards

ABB’s solutions reflect decades of expertise in industrial automation and electrification. By referencing GISTM and collaborating with Boliden, ABB demonstrates authority and trustworthiness. These practices reinforce confidence among stakeholders and regulators.

Author Commentary: Trends in Mining Automation

Industrial automation in mining increasingly focuses on resilience and sustainability. PLCs and DCS platforms now integrate predictive analytics, enabling proactive maintenance. In my view, modular electrification will become standard practice, especially in regions with harsh climates. Companies that invest early in automation will gain competitive advantages in efficiency and compliance.

Application Scenarios and Solutions

-

Tailings dam monitoring: Real‑time data from DCS ensures safe water management.

-

Energy optimization: Variable speed drives reduce energy consumption in pumping stations.

-

Rapid expansion projects: Modular e‑houses allow mines to scale operations quickly.

-

Environmental restoration: Automated systems support reclamation by managing water recycling.