Robot Software Market Outlook: Driving Industrial Automation with AI and Control Systems

- 〡

- 〡 by WUPAMBO

Growing Demand for Intelligent Robot Software

Industrial automation continues to expand as companies seek advanced robot software to improve precision and coordination. Manufacturers and logistics providers increasingly rely on software-driven control systems, including PLC and DCS platforms, to streamline factory automation. Moreover, AI-enabled solutions now support autonomous decision-making, predictive behavior, and real-time adaptation across diverse industries.

Collaborative Robots and Simplified Programming

The rise of collaborative robots highlights the need for intuitive programming tools accessible to non-technical users. Simplified workflow development reduces barriers to adoption and accelerates deployment in industrial automation environments. As a result, robot software vendors focus on user-friendly interfaces and standardized communication protocols to ensure seamless human-machine collaboration.

Key Challenges in Integration and Cybersecurity

Despite rapid growth, integration complexity and cybersecurity risks remain critical challenges. Many organizations struggle with interoperability across heterogeneous platforms, which slows adoption. Therefore, developers emphasize resilient middleware and secure communication layers to protect factory automation systems from cyber threats while maintaining operational reliability.

Cloud-Native Control Systems and Simulation Platforms

Future growth will rely on cloud-native robot control systems that enable scalable deployment and remote management. In addition, simulation platforms and digital twins provide faster validation, reduced downtime, and improved lifecycle optimization. These technologies strengthen industrial automation by allowing engineers to test workflows virtually before implementation.

Advancements in Edge Processing and Analytics

Edge computing reshapes robot deployment strategies by enabling real-time diagnostics and adaptive learning at the device level. Intelligent analytics further enhance predictive maintenance and data-driven optimization, reducing downtime in manufacturing and logistics. Consequently, companies achieve greater flexibility and efficiency in distributed robotic fleets.

Major Companies Leading the Market

Several global players drive innovation in robot software, including ABB, AIBrain, Brain Corp, CloudMinds, IBM, and H2O.ai. . These firms invest heavily in AI, control systems, and industrial automation solutions. Their strategies include mergers, acquisitions, and partnerships to strengthen market presence and expand product portfolios.

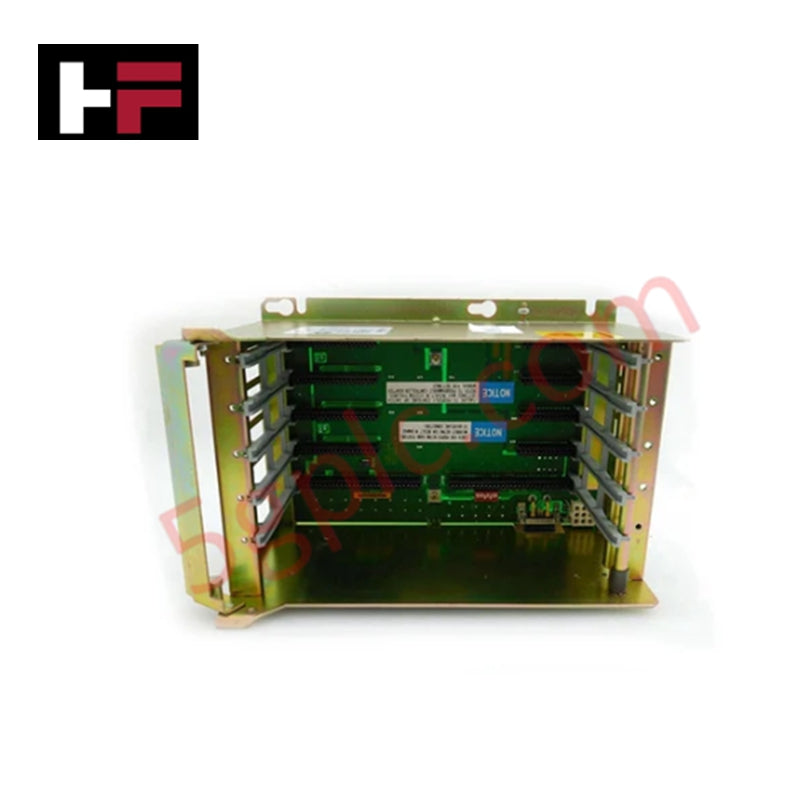

Market Segmentation by Software Type

Robot software spans multiple categories: recognition software, simulation tools, predictive maintenance platforms, data management solutions, and communication management systems. Each type plays a vital role in factory automation, supporting tasks from visual recognition to workflow orchestration.

Industrial and Service Robot Applications

Industrial robots dominate manufacturing and logistics, while service robots expand into healthcare, retail, and inspection. Both categories rely on advanced software for motion planning, safety frameworks, and real-time decision-making. In addition, flexible programming environments ensure consistent performance across varied operational settings.

Global Market Expansion Across Regions

The robot software market grows across North America, Europe, Asia Pacific, Latin America, and the Middle East. Regional adoption depends on regulatory frameworks, digitalization levels, and investment in industrial automation infrastructure. As a result, companies must adapt strategies to meet evolving compliance and performance expectations.

Author Insights and Industry Commentary

Robot software is no longer a niche tool but a core enabler of industrial automation. In my view, the integration of AI-driven analytics with PLC and DCS systems will define the next phase of factory automation. Companies that embrace cloud-native architectures and digital twins will gain competitive advantages in scalability and reliability. However, cybersecurity must remain a top priority, as connected robots increase exposure to digital threats.

Application Scenarios and Solutions

-

Manufacturing: Predictive maintenance software reduces downtime and improves production efficiency.

-

Logistics: Simulation platforms optimize warehouse robotics and streamline supply chain operations.

-

Healthcare: Service robots with recognition software assist in patient monitoring and diagnostics.

-

Retail: AI-driven robots enhance customer engagement and automate inventory management.