Global Slotless BLDC Motor Market for Industrial Robots 2025–2035: Growth and Innovation

- 〡

- 〡 by WUPAMBO

Market Growth in Industrial Automation

The global slotless BLDC motor market for industrial robots is set for strong expansion. Revenue will rise from USD 20.4 million in 2025 to USD 44.5 million by 2035. This reflects an 8.2% CAGR and a 2.2X increase. As a result, demand for high‑precision motion systems in industrial automation, PLC‑based control systems, and collaborative robots continues to accelerate.

Rising Demand from Collaborative and Precision Robots

Between 2025 and 2030, cobots and lightweight robotic arms will drive rapid adoption. Market value will grow to USD 30.2 million, accounting for 41% of the decade’s expansion. Manufacturers now integrate slotless BLDC motors with servo drives and encoder systems. Therefore, industries such as electronics assembly, medical robotics, and semiconductor automation benefit from smooth, cogging‑free motion and reduced electromagnetic interference.

Technology Advances Define 2030–2035 Expansion

From 2030 onward, innovation will focus on miniaturization and compact high‑torque solutions. Market value will reach USD 44.5 million by 2035, with 59% of incremental growth in this phase. Moreover, plug‑and‑play motor systems, predictive diagnostics, and integrated controllers will reshape robotic architecture. Motors under 20mm diameter will support next‑generation service robots and collaborative automation platforms.

Regional Leadership in Robotics Innovation

East Asia leads global adoption, with Japan, South Korea, and China driving demand for compact precision motors. Europe follows, supported by Germany, Italy, and France, where advanced factory automation and DCS systems dominate. In addition, North America maintains a strong share through medical device manufacturing and robotics research clusters.

Market Snapshot and Key Metrics

By 2025, market value stands at USD 20.4 million. By 2035, it will reach USD 44.5 million. CAGR remains at 8.2%. Leading players include Portescap, FAULHABER, Maxon Motor, AMETEK, and Allient Inc. Motors sized between 20mm and 30mm dominate due to torque efficiency and thermal stability. Multi‑joint robots represent the largest application segment, holding 38% market share.

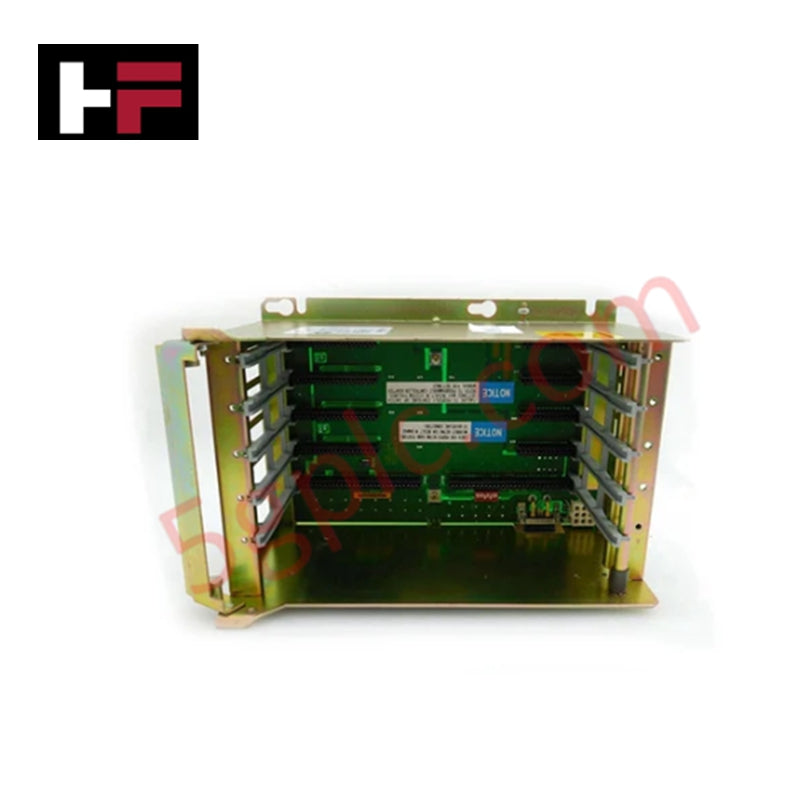

Application Trends in Factory Automation

Slotless BLDC motors sized 20–30mm are widely used in industrial robot joints, cobots, and high‑precision assembly lines. Ultra‑compact motors under 20mm expand in surgical robotics and micro‑assembly. Larger motors above 30mm serve high‑payload robots and warehouse automation. Therefore, articulated multi‑joint robots remain the leading application, benefiting from smooth multi‑axis coordination.

Key Drivers and Industry Challenges

Market expansion is driven by collaborative robot adoption, miniaturization in electronics and medical automation, and semiconductor cleanroom requirements. Integrated motor‑controller systems simplify robotic design. However, challenges include premium pricing and torque limitations at larger diameters. Innovation in winding technology and thermal design continues to address these barriers.

Author’s Insights and Industry Commentary

Slotless BLDC motors highlight how industrial automation evolves toward precision, efficiency, and flexibility. In my view, the integration of motors with advanced encoders and predictive diagnostics reflects a broader trend toward intelligent control systems. Manufacturers should invest in scalable solutions that combine PLC, DCS, and robotics platforms to remain competitive.

Application Scenarios and Solutions

-

Industrial Robots: Smooth torque for multi‑joint operations.

-

Collaborative Robots: Safe, vibration‑free actuation for human‑robot interaction.

-

Semiconductor Automation: Low interference motors for cleanroom environments.

-

Medical Robotics: Ultra‑compact motors for surgical precision.

-

Factory Automation: Integrated motor‑controller systems simplifying control architecture.