Dangote and Honeywell Partnership to Transform Refinery Output with Industrial Automation

- 〡

- 〡 by WUPAMBO

Expanding Refinery Capacity with Advanced Control Systems

Dangote Petroleum Refinery and Petrochemicals FZE has entered a strategic partnership with Honeywell to boost refinery output. The collaboration leverages Honeywell’s refining and petrochemical solutions, including proprietary catalysts, advanced equipment, and automation technologies. As a result, production capacity will rise from 650,000 barrels per day to 1.4 million barrels per day within three years. This expansion positions Dangote as the world’s largest refinery, strengthening Nigeria’s energy independence and reducing reliance on fuel imports.

Industrial Automation Enhances Energy Security

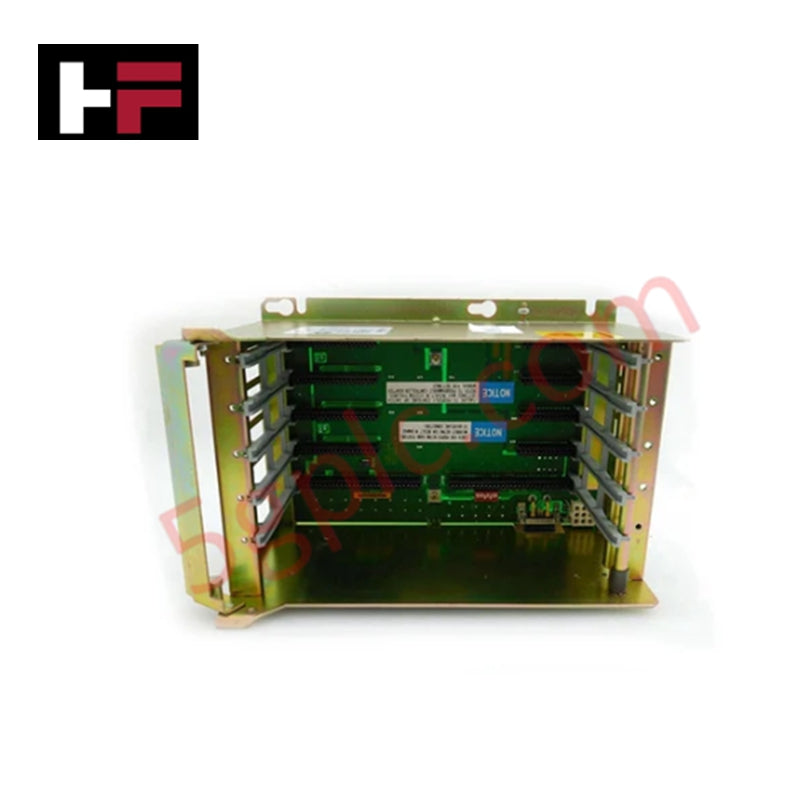

Honeywell’s expertise in industrial automation, PLC, and DCS systems plays a central role in this project. By integrating advanced control systems and factory automation solutions, the refinery can optimize crude processing and improve operational efficiency. According to Aliko Dangote, this partnership sets new industry benchmarks and supports Nigeria’s economic growth. Moreover, Honeywell’s technologies ensure consistent performance, minimize downtime, and enhance safety standards, which are critical in large-scale refinery operations.

Proven Technology and Licensing for Petrochemical Growth

Honeywell has supported Dangote’s refinery for nearly a decade, providing process technology and automation solutions. The latest agreement includes Honeywell’s Oleflex technology, which converts propane into propylene through catalytic dehydrogenation. This innovation will enable Dangote to produce 750,000 metric tonnes of propylene annually, raising polypropylene output to 2.4 million metric tonnes per year. In addition, Honeywell’s global experience—spanning over 6,000 licensed facilities—ensures that the expansion maximizes ROI and accelerates product delivery to market.

Author’s Insight: Industrial Automation as a Growth Driver

This partnership highlights how industrial automation and control systems are reshaping the energy sector. By combining Honeywell’s automation expertise with Dangote’s scale, the project demonstrates how technology can drive efficiency, sustainability, and competitiveness. In my view, the integration of PLC and DCS platforms will not only improve production but also provide predictive maintenance capabilities, reducing long-term costs. Such collaborations illustrate the growing importance of automation in achieving energy security and industrial resilience.

Application Scenarios and Solutions

-

Refinery Operations: Use of advanced DCS systems for real-time monitoring and control.

-

Petrochemical Production: Oleflex technology integrated with factory automation to boost propylene output.

-

Energy Security: Automation-driven efficiency reduces dependency on imported fuels.

-

Predictive Maintenance: PLC-based monitoring ensures equipment reliability and minimizes downtime.

-

Scalable Growth: Modular automation solutions allow future expansion without major infrastructure changes.