Critical Factors Leading to PLC System Failures in Industrial Automation

- 〡

- 〡 by WUPAMBO

Mitigating Power Supply Instability and Voltage Spikes

Power issues represent the most frequent catalyst for automation system breakdowns. PLCs typically operate on 230V AC or 24V DC. However, frequent outages and voltage surges can degrade internal circuitry over time. Moreover, high-noise devices like Variable Frequency Drives (VFDs) often introduce harmful harmonics into the power line.

Industrial facilities must utilize high-quality Uninterruptible Power Supplies (UPS) to ensure consistent voltage. In addition, installing single-phase preventer relays can safeguard the system by detecting phase failures before they reach the PLC hardware.

Preventing CPU Overheating and Watchdog Timeouts

The CPU is the most critical component, yet it often fails due to inadequate thermal management. If a control panel lacks proper ventilation, the CPU temperature will climb, eventually scorching delicate microprocessors. Aside from physical heat, logical errors can also "crash" the CPU.

For instance, infinite logic loops or excessively long scan times trigger watchdog timeout errors. Therefore, programmers should optimize code to stay within safe cycle times. Furthermore, interrupting power during a firmware download can permanently "brick" the controller, making stable power during maintenance non-negotiable.

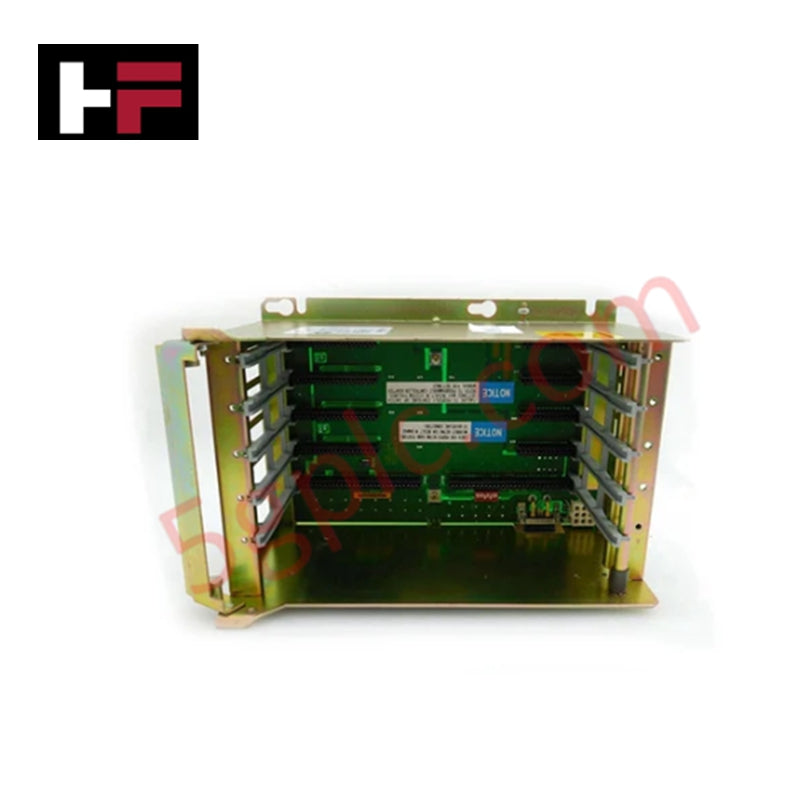

Managing I/O Module Stress and Backplane Integrity

Input/Output (I/O) modules bridge the gap between digital logic and physical field devices. However, weak earthing or improper wiring often causes these modules to fail. High-voltage transients from the field can travel back to the module, potentially shorting the entire CPU backplane.

Regular inspections of terminal blocks are necessary to identify loose connections. Consequently, engineers should use galvanic isolation or interposing relays to protect sensitive analog and digital cards from field-side electrical faults.

Solving Network Card Failures and Communication Latency

Modern industrial automation relies heavily on protocols like Ethernet/IP, Modbus TCP, and CANOpen. A failure in the communication port or a damaged network cable results in immediate data loss and system-wide halts. Poorly configured gateways and routers often exacerbate these issues.

As a result, network infrastructure should be treated with the same priority as the PLC itself. Using industrial-grade switches rather than commercial-grade hardware significantly increases the MTBF (Mean Time Between Failures) for the entire network.

The Hidden Dangers of Inadequate Grounding Systems

Poor grounding is a silent killer in control systems. Almost every component, from the CPU to the network card, requires a solid earthing point. Without it, leakage current can circulate through the hardware, causing permanent damage.

Furthermore, inadequate grounding leads to electromagnetic interference (EMI). This interference often causes "ghost signals" or erratic behavior in sensitive analog sensors. Professional installations must ensure that the signal ground and power ground are correctly referenced to prevent ground loops.

Reducing Human Error in Programming and Version Control

Human error remains a significant contributor to system instability. Writing logic without accounting for safety interlocks or future process conditions can lead to catastrophic malfunctions. Moreover, poor documentation and version control frequently lead to disaster.

For example, a programmer might accidentally download an older, unoptimized backup during a site visit. To prevent this, teams must implement strict version control protocols and always verify the "Last Modified" timestamp before performing a download.

Solution Scenario: Preventing Failure in a Water Treatment Plant

In a large-scale water treatment facility, PLCs are often located in high-humidity environments prone to electrical noise.

-

The Problem: The system experienced frequent "Watchdog" resets and erratic analog flow readings.

-

The Diagnosis: Investigation revealed that nearby high-power pumps were injecting harmonics into the shared power rail, and the PLC cabinet lacked a dedicated ground rod.

-

The Solution: Engineers installed an isolation transformer for the PLC power supply and a dedicated copper earth pit. Additionally, the logic was refactored into modular subroutines to reduce the scan time from 80ms to 25ms.

-

The Result: System uptime increased by 40%, and analog signal precision improved significantly.