ABB Strengthens Data Center Cooling with OctaiPipe AI Investment

- 〡

- 〡 by WUPAMBO

Strategic Partnership in Industrial Automation

ABB has taken a minority stake in OctaiPipe, a UK-based AI company specializing in data center cooling optimization. This move expands ABB’s industrial automation portfolio and supports sustainable growth in the digital infrastructure sector.

Factory Automation Meets AI Innovation

OctaiPipe’s platform integrates federated learning, reinforcement learning, and digital twin modeling to optimize cooling systems. By combining ABB’s factory automation expertise with advanced AI, operators gain real-time control and improved energy efficiency.

Control Systems for Energy Efficiency

ABB Motion Services emphasizes that energy efficiency is no longer optional. By embedding AI-driven control systems into cooling infrastructure, data centers reduce electricity consumption while maintaining operational resilience. This aligns with global sustainability targets.

On-Site Deployment for Data Security

Unlike cloud-based solutions, OctaiPipe deploys its system directly on-site. This design ensures data sovereignty, scalability, and compliance with regulatory standards. Therefore, operators benefit from secure and transparent cooling optimization.

Expanding Reliability Through Lifecycle Support

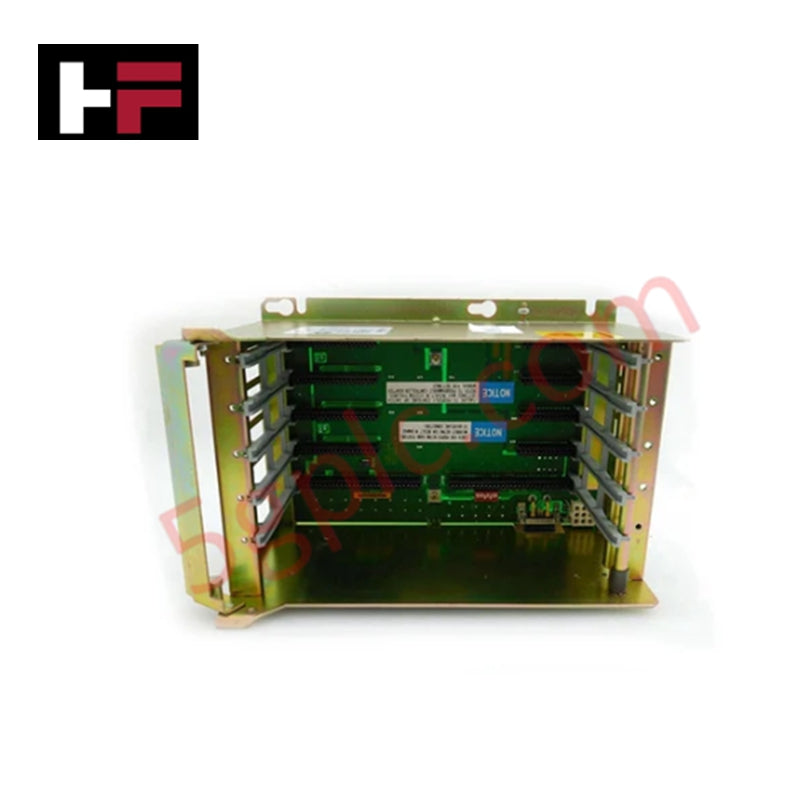

The partnership includes a roadmap for enhancing reliability and performance across data center operations. ABB’s industrial automation expertise in PLC and DCS systems complements OctaiPipe’s AI, creating a holistic approach to lifecycle management.

Industry Context and Author’s Commentary

Data centers are projected to consume more electricity by 2030 than manufacturing energy-intensive goods. In my view, ABB’s investment reflects a critical industry trend: automation and AI must converge to address sustainability challenges. Moreover, integrating AI into control systems demonstrates how industrial automation evolves beyond traditional factory settings into digital infrastructure.

Application Scenarios and Solutions

-

Hyperscale Data Centers: AI-driven cooling reduces energy costs and supports large-scale AI workloads.

-

Edge Facilities: On-site deployment ensures compliance and secure operations in distributed environments.

-

Industrial Automation Integration: PLC and DCS systems coordinate with AI models for precise cooling control.

-

Predictive Maintenance: Digital twins forecast equipment performance, minimizing downtime and extending asset life.