HAL Drives Localization of Honeywell TPE331 Components, Integrating Industrial Automation in Aerospace Sustainment

- 〡

- 〡 by WUPAMBO

HAL’s Strategic Push for Engine Component Indigenization

Hindustan Aeronautics Limited (HAL) accelerates local production of Honeywell TPE331 parts. It targets Do-228 utility and HTT-40 trainer fleets for long-term sustainment. In late November 2025, HAL issued an RFI to Indian manufacturers. The RFI seeks castings, forgings, and finished spares for these turboprop engines. This move shifts HAL from licensed assembly to a self-reliant supply chain. Moreover, it aligns with India’s goal of boosting industrial automation in critical sectors.

Four Decades of TPE331 Expertise at HAL Bengaluru

HAL’s Bengaluru Engine Division has supported TPE331 engines since 1983. It originally built Garrett (now Honeywell) engines under license for Do-228s. To date, the division has delivered 365 new engines and 1,000+ overhauls. Indian Air Force, Navy, and Coast Guard benefit from these services. However, the focus now expands beyond basic production and support. It aims to build a Category-B maintenance ecosystem for major repairs. This ecosystem will reduce reliance on OEM supply chains.

HTT-40 Programme Catalyzes Localization Efforts

The Hindustan Turbo Trainer-40 (HTT-40) programme drives HAL’s accelerated action. The IAF-selected trainer uses the TPE331-12B, an upgraded Do-228 engine variant. The IAF needs over 100 HTT-40 aircraft, demanding steady spare parts flow. In 2022, HAL signed a $100M+ contract with Honeywell for 88 engines. Therefore, localization becomes critical to avoid global supply chain disruptions. It also eliminates delays from export licensing processes. This step ensures the HTT-40 fleet stays operational domestically.

High-Precision Parts Open Doors for Indian Industry

HAL’s RFI targets high-precision components like turbine wheels and impellers. It also seeks shafts, gearbox housings, and fuel controls from local vendors. Qualifying domestic sources cuts foreign exchange outflow and repair times. Moreover, it mirrors HAL’s past successes with Su-30MKI and ALH Dhruv engines. Indian private firms gain access to high-value aerospace supply chains. They will produce parts meeting strict military airworthiness standards. OEM-authorised quality control ensures part reliability and performance.

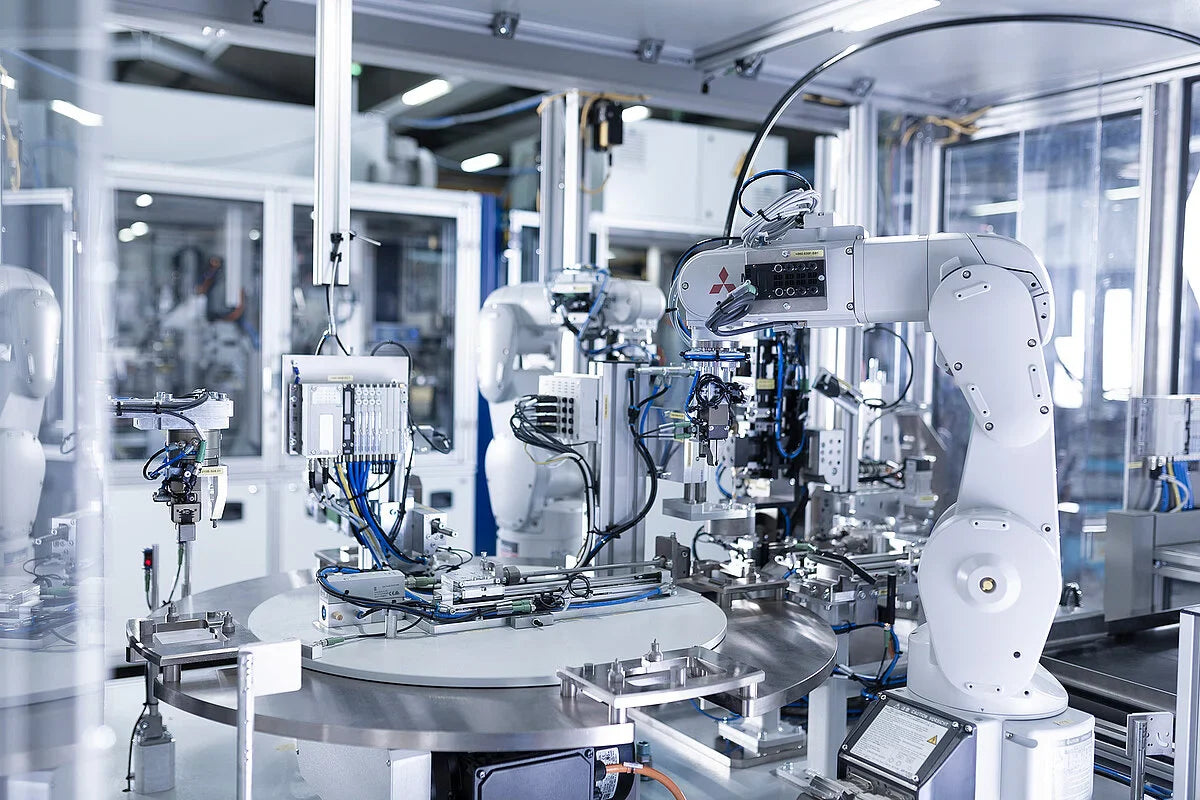

Aligning Aerospace Localization with Industrial Automation Trends

This localization drive intersects with global industrial automation advancements. Modern control systems and PLCs streamline engine component production. They ensure precision and consistency in manufacturing critical parts. DCS manages complex supply chain workflows for seamless operations. These technologies help Indian manufacturers meet aerospace quality benchmarks. In addition, factory automation tools reduce human error in high-precision machining. This alignment positions India as a hub for advanced aerospace component production.

Author’s Insight: Localization as a Catalyst for Sector-Wide Growth

HAL’s initiative is a strategic masterstroke for India’s aerospace and industrial sectors. It reduces dependency on global OEMs and builds domestic technical expertise. The focus on high-precision parts pushes local manufacturers to adopt advanced automation. PLC and DCS integration in production lines will be key to success. Moreover, this model can replicate across other defense and industrial segments. It will drive India’s “Make in India” initiative forward in critical sectors. For automation providers, this creates opportunities to deploy cutting-edge solutions.

Application Case: Integrating Control Systems in Engine Component Production

A leading Indian precision manufacturer can leverage this HAL-driven opportunity. It can integrate Siemens or Allen-Bradley PLCs into its turbine wheel machining lines. The PLCs will control tool movements, ensuring tight tolerances for aerospace use. A DCS will manage the entire workflow, from raw material input to final inspection. Factory automation software will track quality metrics in real time. This setup will help the firm meet HAL’s strict quality requirements. It will also position the firm as a reliable supplier for future aerospace projects. This case shows how industrial automation enables high-value supply chain participation.

- Posted in:

- Honeywell

- Industrial Automation

- PLC and DCS Systems