Product Details

Overview

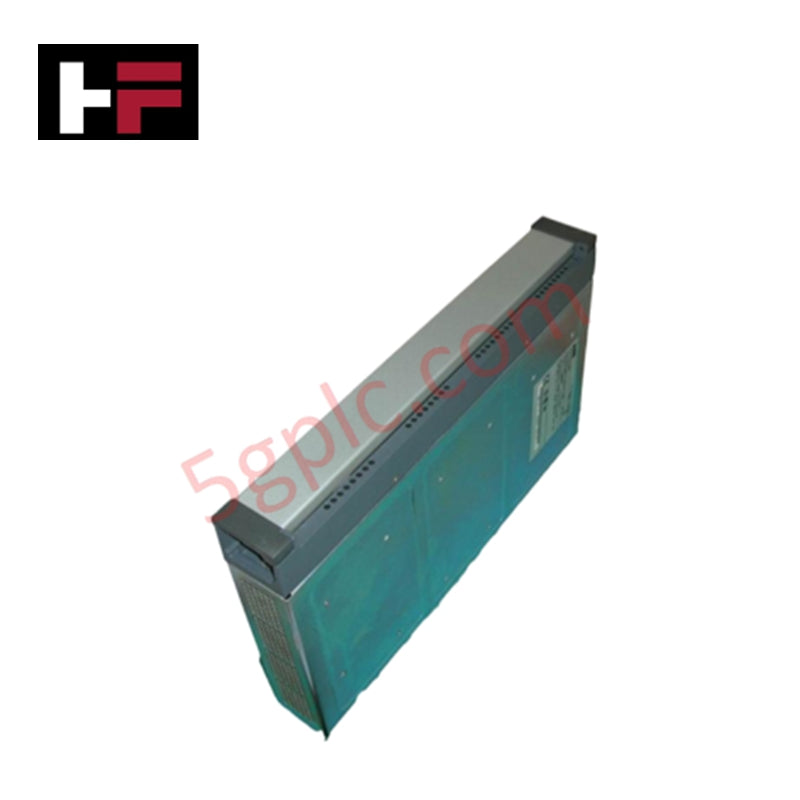

The ABB DA501 (1SAP250700R0001) is a compact digital and analog I/O module from the S500 I/O series, engineered for flexible signal processing in distributed control and automation systems. Designed to integrate seamlessly into ABB’s PLC platforms, it combines digital inputs, analog channels, and configurable I/O functions in a single, space-efficient module. The DA501 delivers high accuracy and robust performance for industrial environments requiring reliable signal acquisition and control.

Technical Specifications

-

Manufacturer: ABB

-

Model Number: DA501

-

Part Number: 1SAP250700R0001

-

Product Type: Digital/Analog I/O Module

-

Product Series: S500 I/O

-

Input Configuration:

-

16 digital inputs, 24 VDC

-

4 analog inputs (U, I, RTD)

-

2 analog outputs (U, I)

-

8 configurable digital I/O channels (24 VDC, 0.5 A)

-

Input Signal Type: Voltage, current, resistance (RTD)

-

Output Signal Type: Voltage or current

-

Power Supply: 24 VDC nominal

-

Isolation: Electrical isolation between analog and digital sections for improved reliability

-

Wiring Type: 1-wire connection

-

Operating Temperature Range: 0°C to +55°C

-

Mounting: DIN rail installation

-

Protection Class: IP20 (suitable for control cabinet environments)

-

Product Net Dimensions:

-

Length: 62 mm

-

Height: 76 mm

-

Width: 67.5 mm

-

Net Weight: 0.121 kg

-

Gross Weight: 0.145 kg

-

Country of Origin: Germany

Key Features

-

Combines digital and analog I/O channels in a single compact unit

-

16 digital inputs for 24 VDC signal processing

-

4 analog inputs for voltage, current, or RTD measurement

-

2 analog outputs for voltage or current control loops

-

8 configurable channels functioning as input or output

-

High precision and stable performance across industrial temperature ranges

-

Modular design compatible with ABB S500 and AC500 automation systems

-

Simplified wiring and fast installation with 1-wire connection design

Application Scenarios

The DA501 is ideal for distributed automation architectures, providing reliable I/O processing in applications such as:

-

Industrial machinery and process control

-

Energy and utility automation systems

-

Building and infrastructure management systems

-

Environmental monitoring and data acquisition units

-

Factory automation with mixed signal types

FAQ

Q: What is the purpose of the ABB DA501 module?

A: The DA501 processes both digital and analog signals, enabling integration of sensors, actuators, and control logic in one module for flexible system design.

Q: How many I/O channels are available on the DA501?

A: The module provides 16 digital inputs, 4 analog inputs, 2 analog outputs, and 8 configurable digital I/O channels.

Q: Is the module suitable for high-temperature environments?

A: Yes, the module operates reliably within the range of 0°C to +55°C.

Q: What communication interface does the DA501 use?

A: The DA501 communicates within ABB’s S500 I/O system, which connects to PLCs via fieldbus or AC500 controllers.

Q: Can the analog inputs handle RTD sensors?

A: Yes, the analog inputs support RTD (Resistance Temperature Detector) sensors, including PT100 and similar types.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.