Product Details

Product Description

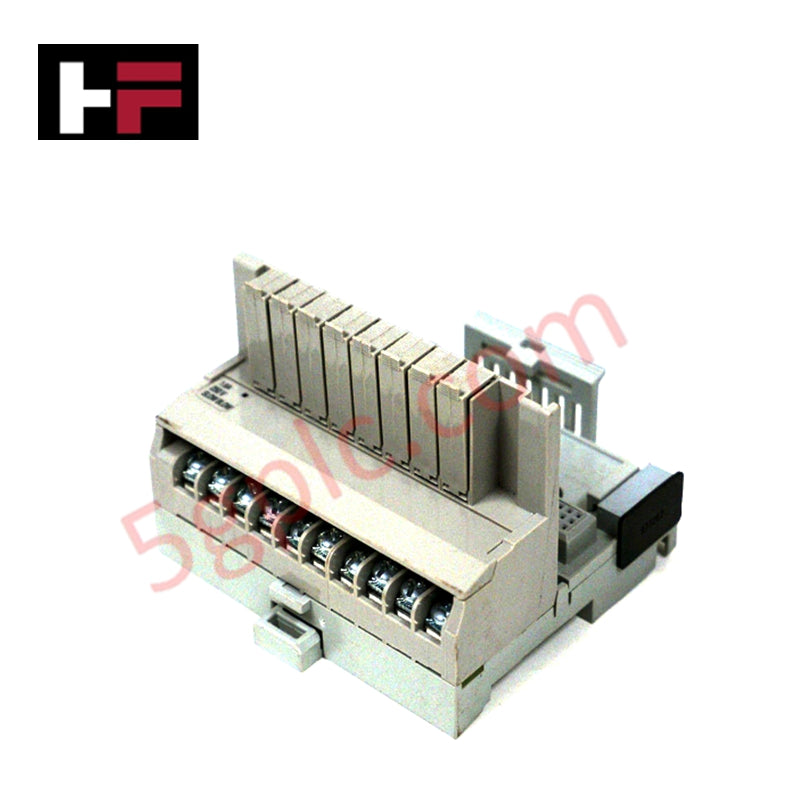

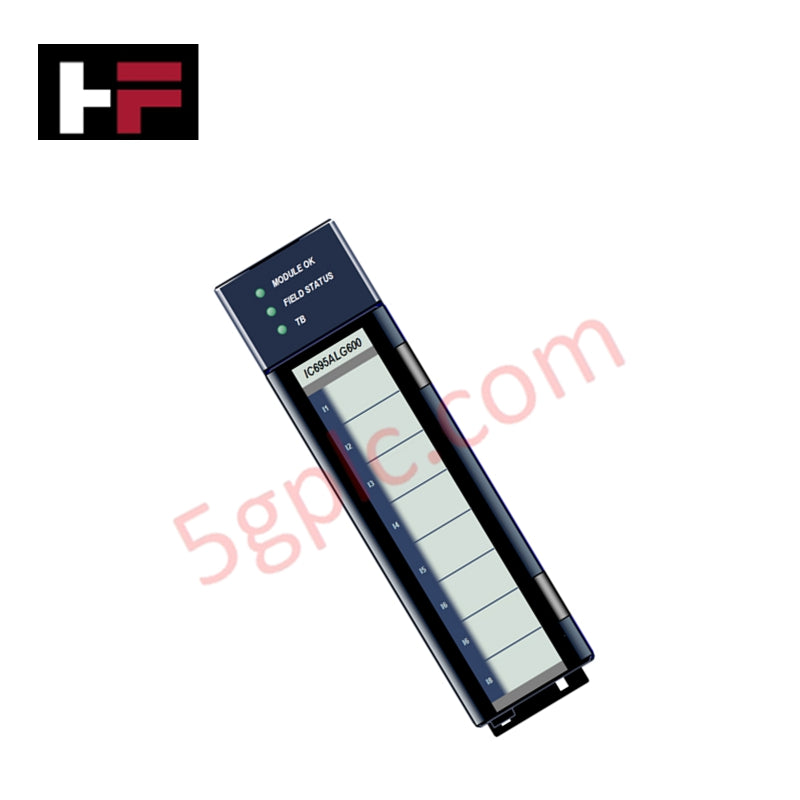

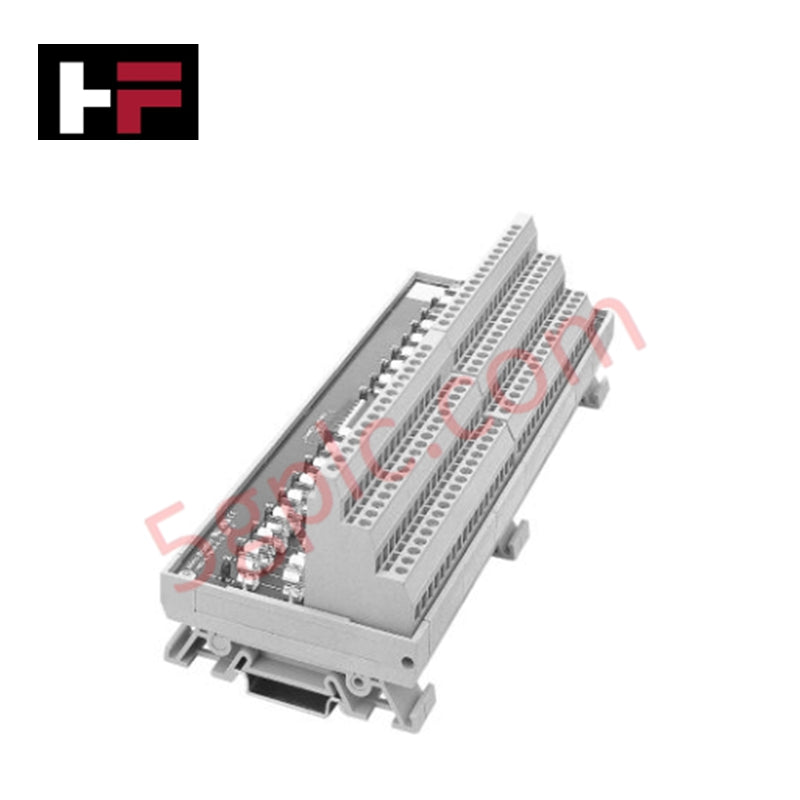

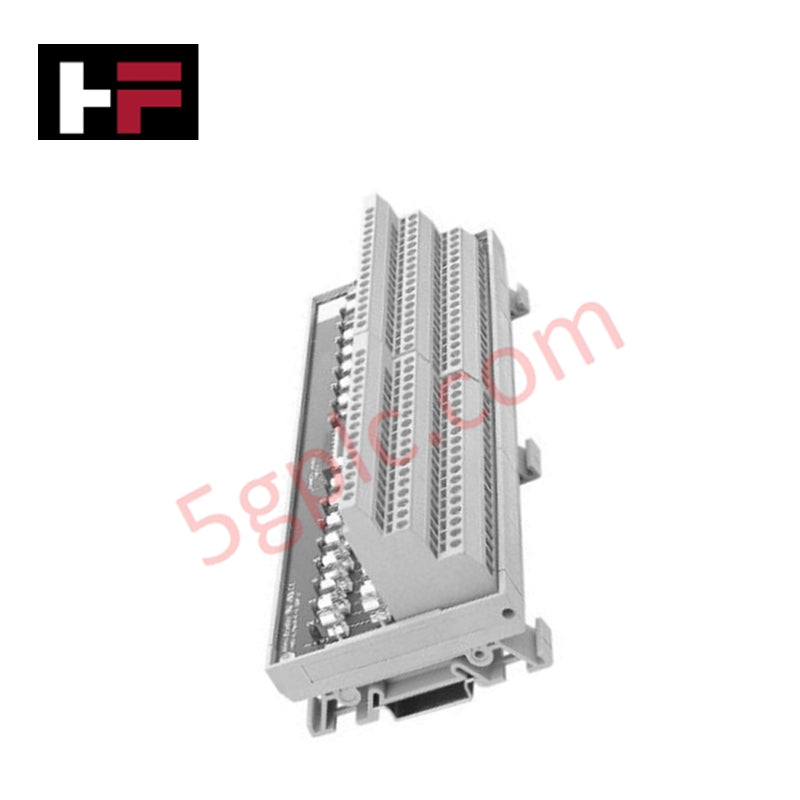

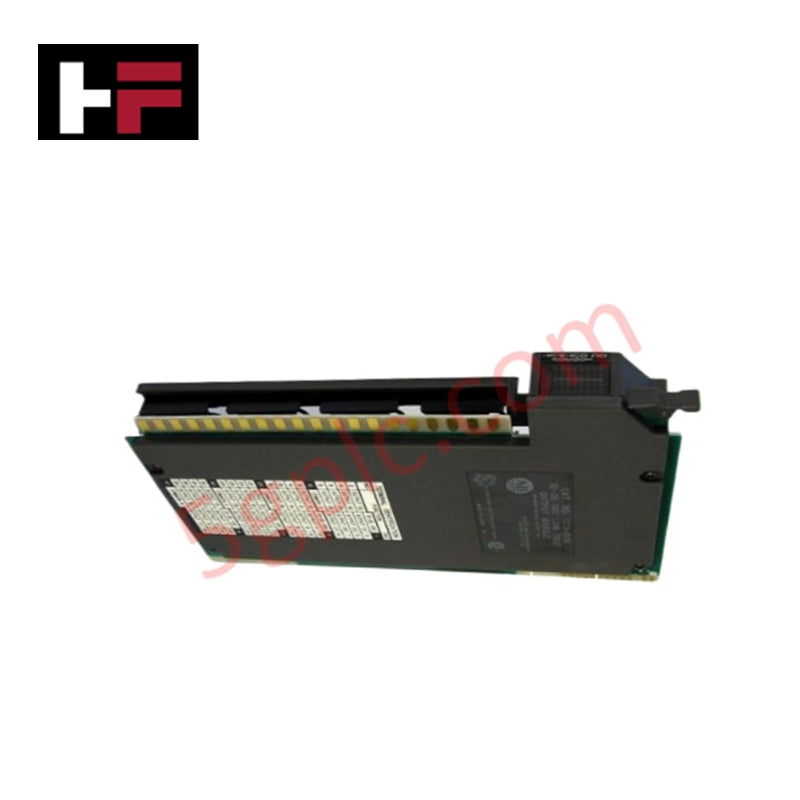

The 1794-TBN is an Allen-Bradley Flex I/O terminal base unit designed to connect and power Flex I/O modules in distributed control systems. It ensures reliable signal transmission between the FlexBus backplane and field wiring, offering flexible configuration and safe operation for industrial automation environments.

Key Specifications

-

Manufacturer: Allen-Bradley

-

Model: 1794-TBN

-

Module Type: Terminal Base Unit

-

Condition: New, factory-sealed

-

Warranty: 12 months

-

Terminal Screw Torque: 1.4 Nm (12 lb-in)

-

Supply Voltage: FlexBus 5V DC, 640 mA

-

I/O Terminals Max Current: 2A

-

V/COM Terminals: 250V AC/DC, 10A, 50/60 Hz

-

Isolation Voltage: 250V DC continuous (field wiring to FlexBus), 2500V DC/sec tested

-

Enclosure: Open-style, no housing

-

Recommended Mounting: Compatible with all Flex I/O modules

-

Safety Note: Disconnecting switch does not break load current; always switch circuits under no-load conditions

Applications

-

Supports Allen-Bradley Flex I/O modules for distributed control networks

-

Suitable for modular PLC systems in manufacturing, process control, and material handling

-

Provides secure connections between field wiring and FlexBus backplane

FAQ

-

Q: Can the 1794-TBN terminal base unit be used with all Flex I/O modules?

A: Yes, it is compatible with standard Flex I/O modules designed for the 1794 series. -

Q: Is a protective enclosure required?

A: No, the terminal base is open-style but should be installed in a control panel or protective enclosure to meet safety standards.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.