How to Train Your Maintenance Team for Industrial Automation Systems

- 〡

- 〡 by WUPAMBO

Properly training your maintenance team is crucial to ensure smooth operations and prevent costly downtime in modern industrial automation environments. With factory automation increasingly integrating PLCs, DCS, SCADA, and IoT-enabled devices, maintenance personnel need advanced skills to manage complex control systems efficiently. This guide outlines a structured approach to developing a highly capable maintenance workforce.

Assess Existing Skills and Identify Training Needs

Start by evaluating each technician’s current knowledge in electrical systems, PLCs, and process instrumentation. Understanding skill gaps allows you to design targeted training plans. Identify critical systems in your facility, such as control panels, PLC networks, and SCADA interfaces, to prioritize learning areas. This step ensures resources focus on areas that impact operational continuity the most.

Teach the Fundamentals of PLC and Control Systems

Maintenance engineers should first understand the difference between PLC-based and conventional electrical systems. Unlike manual or relay-based setups, PLCs require logic programming for automation. Training should cover I/O wiring, CPU architecture, memory usage, power supplies, and communication protocols. These basics create a mental map for troubleshooting and prevent errors during live operations. Courses, hands-on workshops, or guided video tutorials are effective ways to build this foundation.

Introduce Key Automation Software Tools

Once engineers understand PLC basics, expose them to relevant software used in your plant, including PLC programming, SCADA, HMI, and DCS platforms. Training should focus on practical tasks: uploading and downloading programs, safely monitoring live systems, interpreting fault codes, and fine-tuning parameters. Familiarity with software reduces dependency on vendors and accelerates problem-solving during downtime.

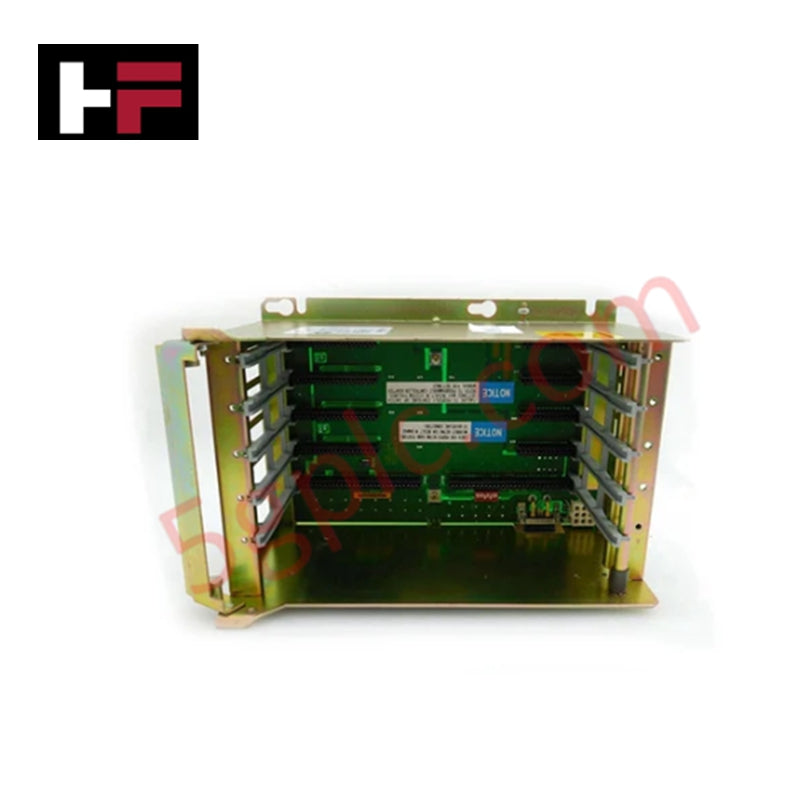

Provide Hands-On Hardware Troubleshooting Exercises

Set up a dedicated training panel simulating your actual plant configuration, including PLCs, HMIs, SCADA, and field instruments. Introduce controlled hardware faults, such as open circuits, miswired inputs, or faulty sensors. Ask technicians to troubleshoot using electrical drawings and diagnostic tools. Repeated practice strengthens their ability to handle real-world issues swiftly and safely.

Emphasize Industrial Safety and Standards Compliance

Safety is critical in industrial environments. Technicians must understand international standards such as ISO, IEC, and ISA related to electrical, instrumentation, and automation safety. Proper knowledge of lockout-tagout (LOTO) procedures, electrical hazards, and cybersecurity best practices reduces risk during maintenance tasks. Training should integrate both theoretical knowledge and practical drills.

Focus on Preventive and Predictive Maintenance

Teach your team to anticipate potential failures through preventive and predictive maintenance strategies. Maintain checklists of common issues, simulate fault conditions, and rehearse solutions. Understanding recurring patterns in PLC, DCS, and field devices improves response time and reduces unplanned downtime. Continuous learning about emerging automation technologies further enhances maintenance efficiency.

Foster Cross-Functional Collaboration and Knowledge Sharing

Encourage collaboration between electrical, instrumentation, and control teams. Rotate tasks to expose technicians to different systems and challenges. Senior staff should mentor juniors, promoting knowledge sharing and consistent skill development. Tracking training progress through logs, assessments, and mock drills ensures accountability and continuous improvement.

Keep Training Updated with Emerging Technologies

Industrial automation evolves rapidly. Regular refresher courses, workshops, and vendor-authorized training keep your team updated with new PLC platforms, communication protocols, and control system upgrades. Awareness of trends such as IIoT integration, advanced SCADA analytics, and cybersecurity measures ensures your maintenance team remains agile and capable.

Practical Implementation Example

For example, a manufacturing plant integrating Siemens S7 PLCs with an SCADA system could simulate a sensor failure during training. Maintenance engineers identify the fault, troubleshoot the I/O module, and restore normal operations using diagnostic software. This hands-on approach accelerates learning and improves uptime when similar incidents occur in live operations.

- Posted in:

- control systems troubleshooting

- DCS systems

- factory automation

- industrial safety

- PLC training

- predictive maintenance

- SCADA maintenance