Understanding GE Fanuc Emerson Field Control for Industrial Automation

- 〡

- 〡 by WUPAMBO

Introduction to Field Control I/O in Factory Automation

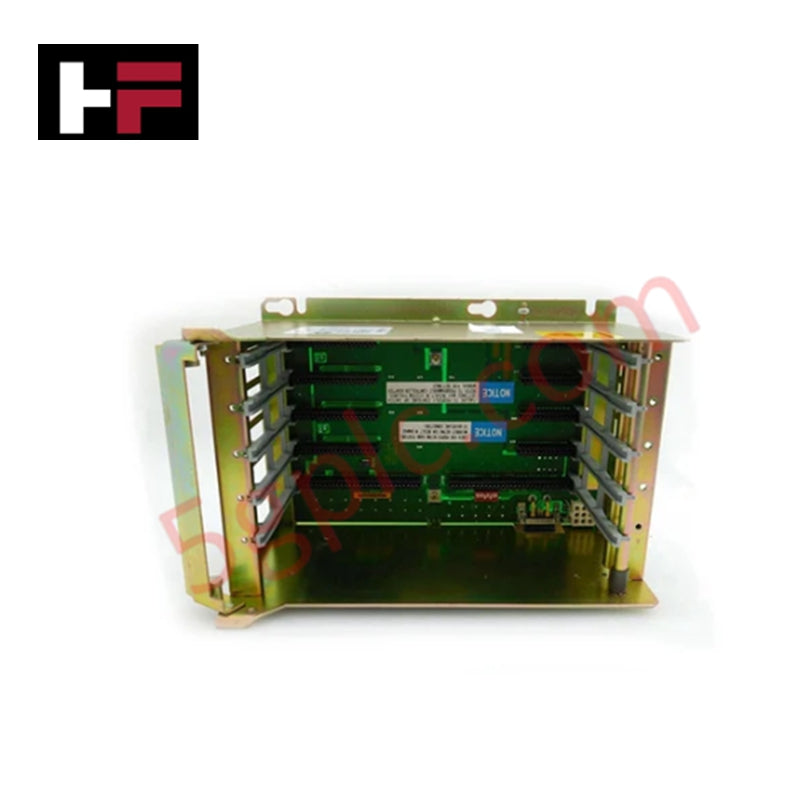

GE Fanuc Emerson’s Field Control I/O was a compact, DIN‑rail-mounted distributed I/O system widely used in industrial automation. Engineers applied it primarily in process industries such as water treatment, chemical plants, and utilities. Its integrated terminal blocks and electronics minimized panel space and reduced wiring complexity, improving system efficiency.

Key Features of GE Fanuc Field Control Modules

Field Control modules combined rugged hardware with user-friendly installation. The system supported various I/O types, including analog and digital signals, and simplified PLC and DCS integration. Moreover, its modular design allowed incremental expansion, making it suitable for mid-sized industrial control systems.

Obsolescence and Modern Alternatives

Although Field Control I/O served factories reliably, GE has discontinued the product line. Consequently, engineers must rely on spare parts and maintenance for legacy plants. For new installations, modern remote I/O systems provide better diagnostics, faster communication, and compatibility with current industrial automation protocols such as Modbus, EtherNet/IP, and ProfiNet.

Implications for Industrial Automation Design

Using outdated I/O systems can increase downtime and maintenance costs. Therefore, integrating contemporary control systems enhances reliability and scalability. Designers should consider future-proofing factory automation with advanced PLCs, DCS platforms, and smart I/O modules that support predictive maintenance and real-time monitoring.

Expert Insight on System Upgrades

Switching from legacy Field Control systems to modern I/O solutions is a strategic decision. Engineers benefit from reduced wiring errors, improved network diagnostics, and easier integration with modern control architectures. Moreover, this shift aligns with Industry 4.0 objectives, boosting operational efficiency and data-driven decision-making.

Conclusion

GE Fanuc Emerson Field Control I/O once played a critical role in industrial automation. While still functional for existing plants, its discontinuation highlights the importance of upgrading to modern control systems. Industrial engineers should prioritize scalable, protocol-compatible I/O solutions to maintain efficiency, reliability, and future readiness.

- Posted in:

- DCS control

- factory automation

- Field Control I/O

- GE Fanuc Emerson

- industrial control panels

- modern automation technology

- PLC systems

- process control systems

- remote I/O modules