Product Details

Overview

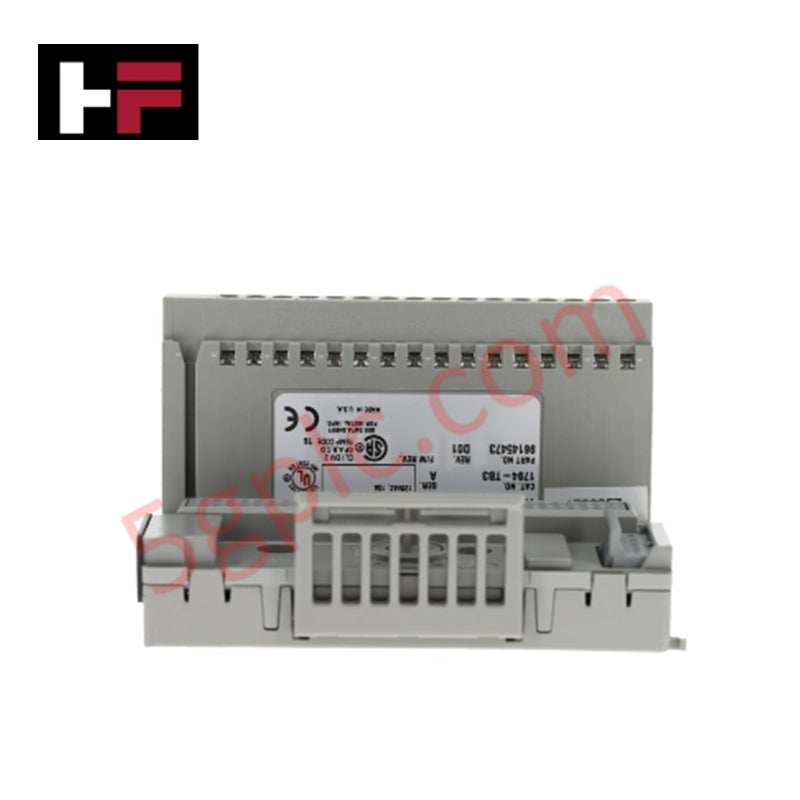

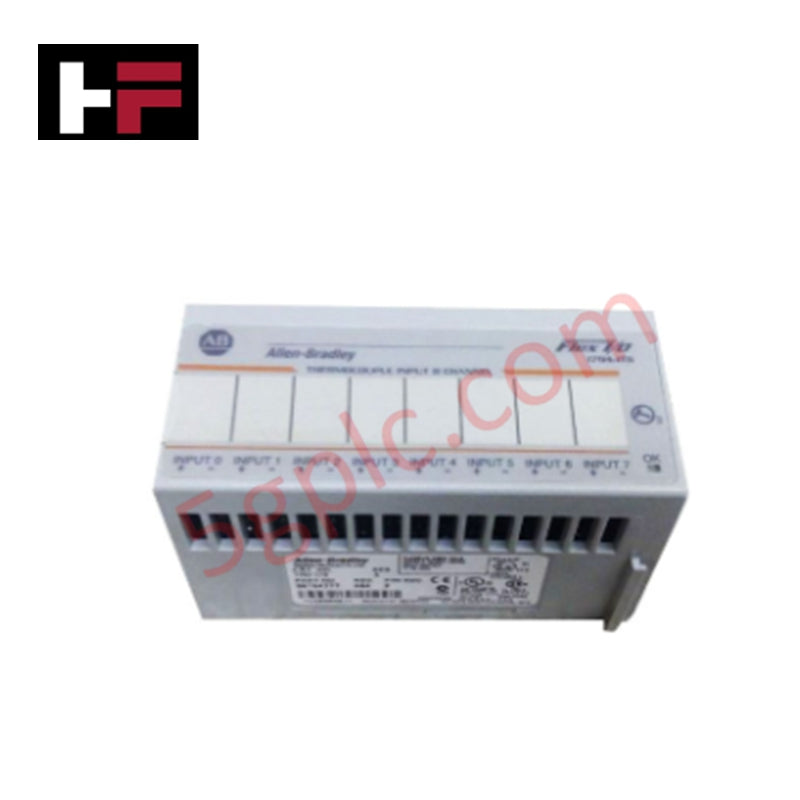

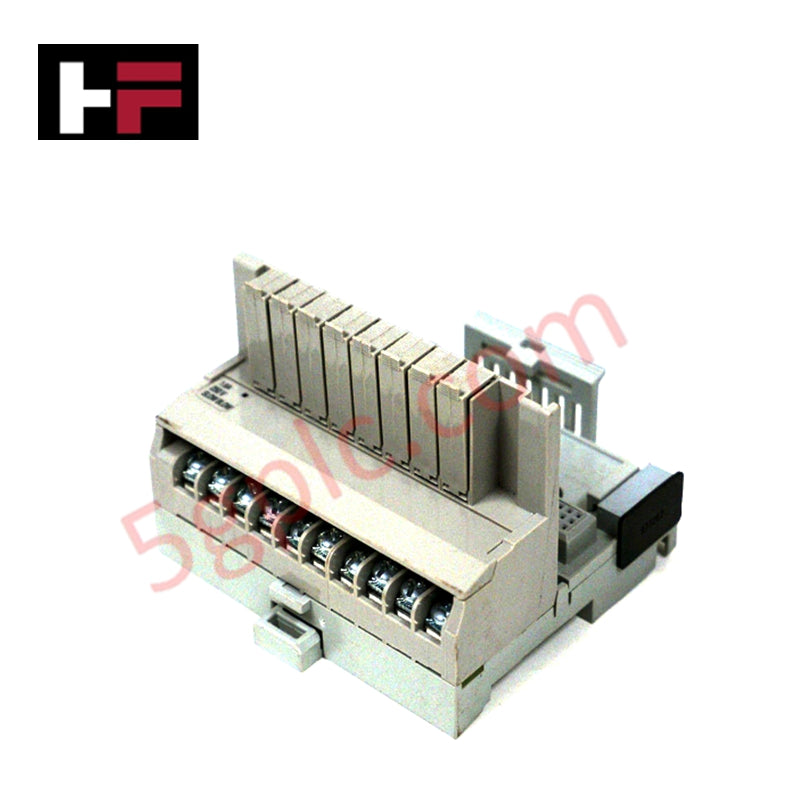

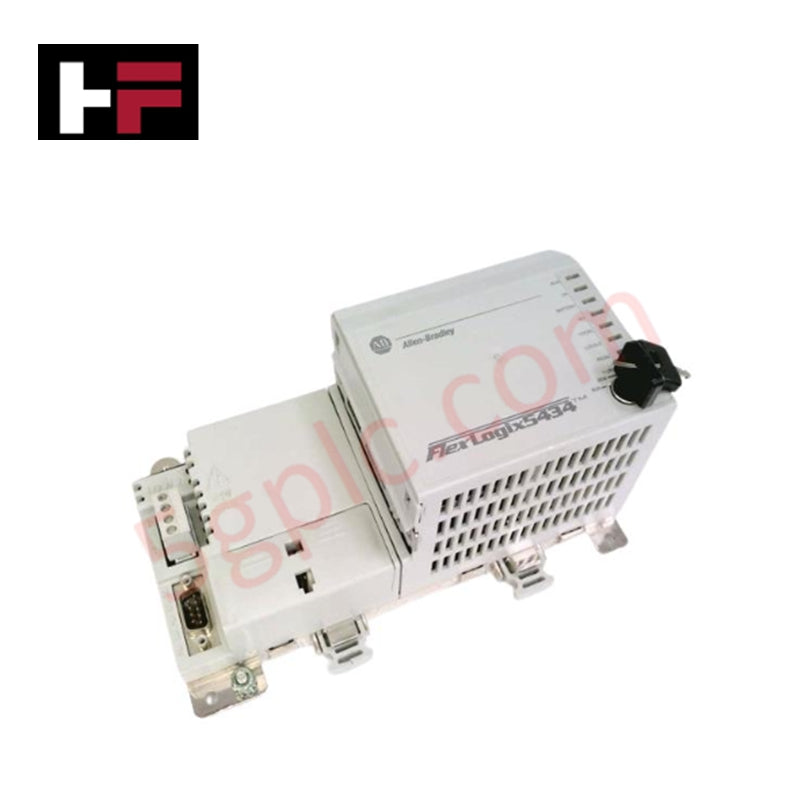

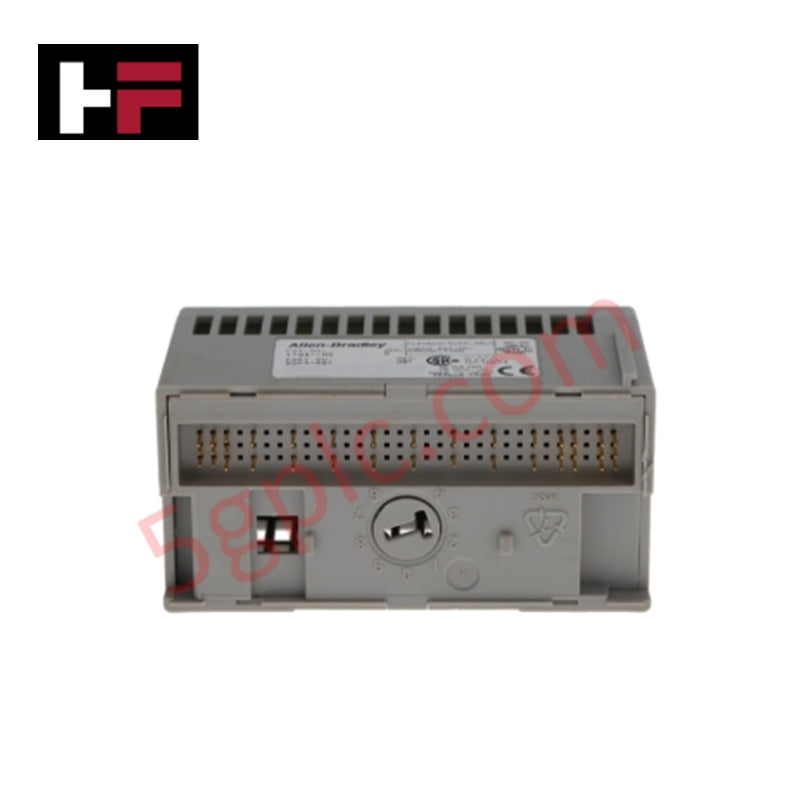

The Allen-Bradley 1794-IRT8 is a high-precision FLEX I/O analog module designed to measure thermocouple and RTD signals. It supports 8 input channels, divided into two groups of 4, and integrates seamlessly with terminal base units 1794-TB3G, 1794-TB3GS, and 1794-TB3GK. The module provides reliable signal acquisition for industrial monitoring and process control applications.

Technical Specifications

-

Manufacturer: Allen-Bradley

-

Model / Part Number: 1794-IRT8

-

Product Type: FLEX I/O Thermocouple/RTD Input Analog Module

-

Number of Inputs: 8 channels (2 groups of 4)

-

Compatible Terminal Bases: 1794-TB3G, 1794-TB3GS, 1794-TB3GK

-

Input Voltage Ranges:

-

Thermocouples: -40…100 mV DC

-

RTDs: 0…325 mV DC

-

-

Resolution: 14 bits

-

Isolation Voltage: 50 V continuous, Basic insulation; type tested at 1365 V AC for 60 s (between field side and system). No isolation between channels

-

FlexBus Current: 20 mA nominal

-

Power Dissipation: 3.0 W max @ 31.2 V DC

-

Thermal Dissipation: Max 10.2 BTU/hr @ 31.2 V DC

-

Keyswitch Positions: 3

-

Indicators: Red/green power status LED

-

Operating Humidity: 5–95% non-condensing (IEC 60068-2-30 Test Db)

-

Vibration Resistance: 5 g @ 10–500 Hz (IEC 60068-2-6 Test Fc)

-

Dimensions (L x W x H): 6.9 × 9.4 × 9.4 cm

-

Weight: 2 kg

Applications

Ideal for precise temperature monitoring in manufacturing processes, chemical plants, and energy systems. Supports integration with existing FLEX I/O networks for scalable and reliable process control.

FAQ

Q: Can this module be used with all FLEX I/O bases?

A: It is compatible with 1794-TB3G, 1794-TB3GS, and 1794-TB3GK terminal bases.

Q: What types of sensors can it read?

A: Supports both thermocouples (-40…100 mV DC) and RTDs (0…325 mV DC).

Q: Is there isolation between individual channels?

A: No, individual channels are not isolated; isolation is provided between field and system side only.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.