Product Details

Product Description

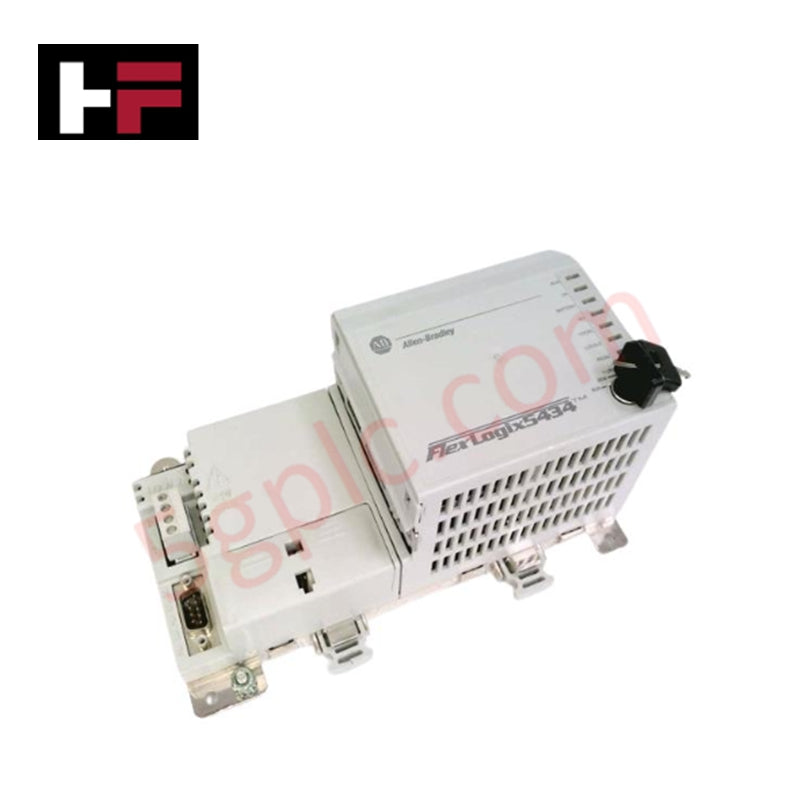

The 1794-L34 is a Flex I/O controller from Allen-Bradley, designed for efficient distributed control and reliable system integration. Compact yet powerful, it supports extended I/O connections and DIN rail or panel mounting, making it ideal for modular industrial setups.

Key Features and Specifications:

-

Controller Type: FlexLogix / Flex I/O

-

Part Number: 1794-L34

-

User Memory: 512 KB

-

Nominal Voltage: 24V DC (range 19.2–31.2 VDC)

-

Input Current: Max 0.85A at 24V DC

-

Backplane Current: 653 mA at 5.1V DC maximum

-

Power Dissipation: 25.5 W at 19.2V; 20.4 W at 24V DC

-

Thermal Dissipation: 87 BTU/hr at 19.2V

-

Isolation Voltage: 30V DC continuous, tested up to 850V DC for 60 s

-

Mounting Options: DIN Rail (steel 35 x 7.55mm, AB 199-DR1 / 46277-3) or Panel mount

-

Flexbus Cable Support: 1 ft (1794-CE1) and 3 ft (1794-CE3)

-

Power Connector Torque: 0.6–0.8 N·m

-

Operating Temperature: 0–60°C

-

Storage Temperature: -40–85°C

-

Weight: 1.69 lbs (0.77 kg)

Applications:

-

Distributed control for modular manufacturing systems

-

Remote I/O management for automation panels

-

Process monitoring with extended local I/O

FAQ / Notes:

-

Compatible with Allen-Bradley Flex I/O modules and FlexBus cabling

-

DIN rail mounting recommended for ease of installation

-

Memory expansion not supported; 512 KB onboard

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.