Product Details

Description

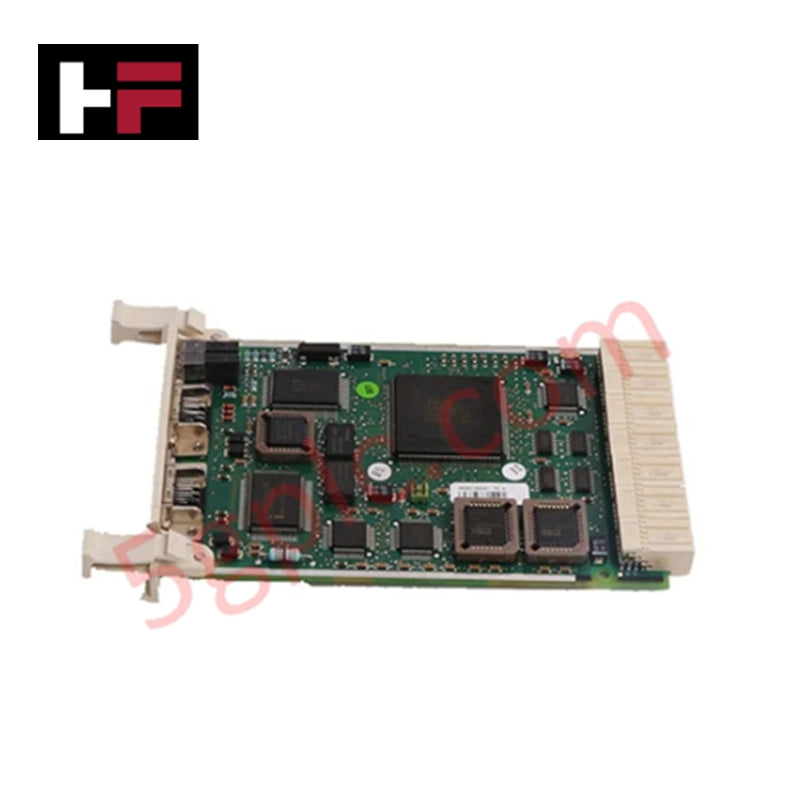

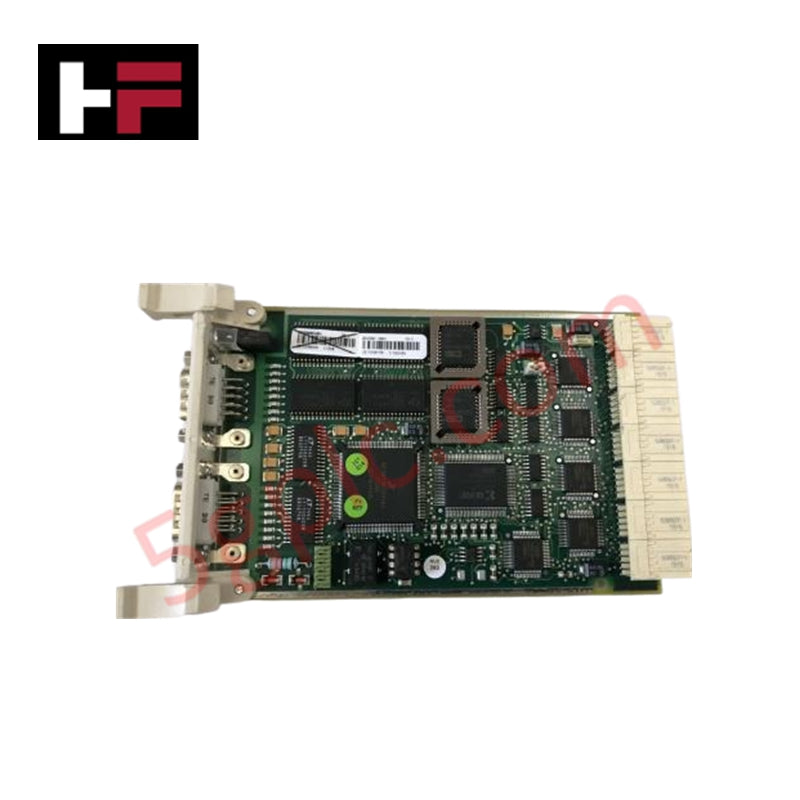

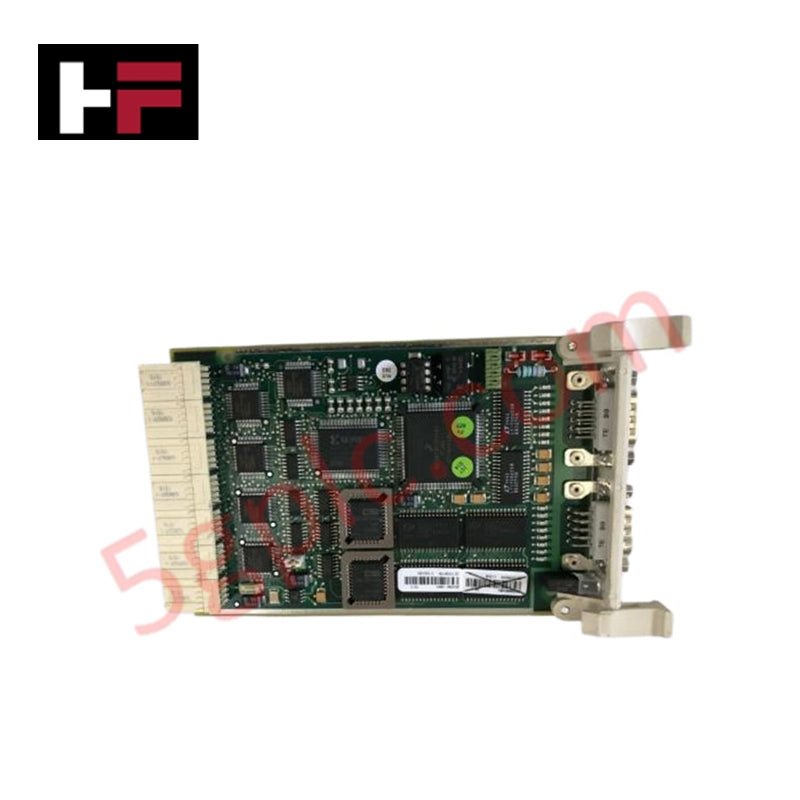

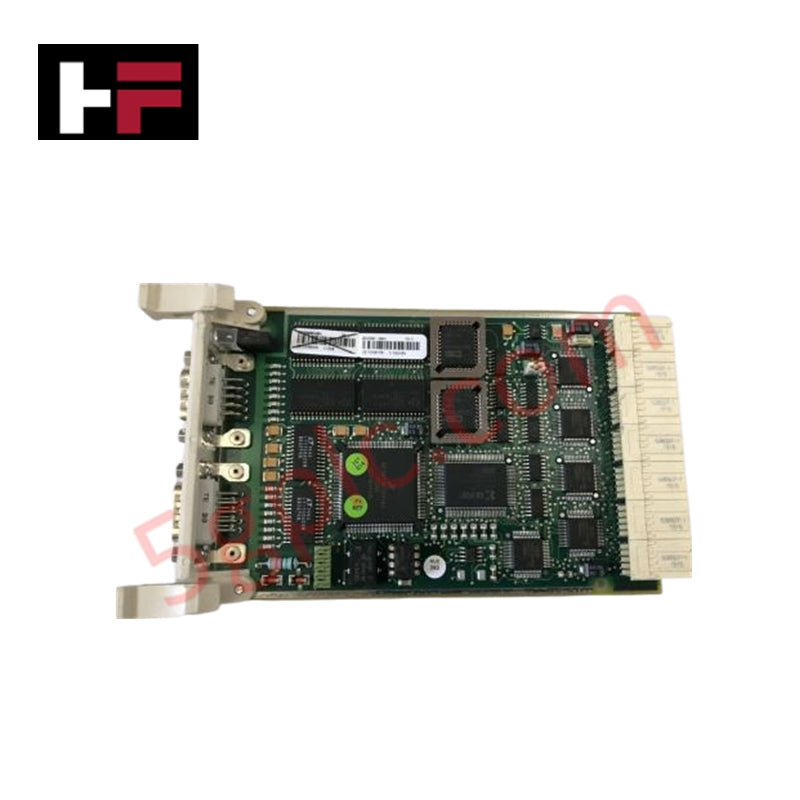

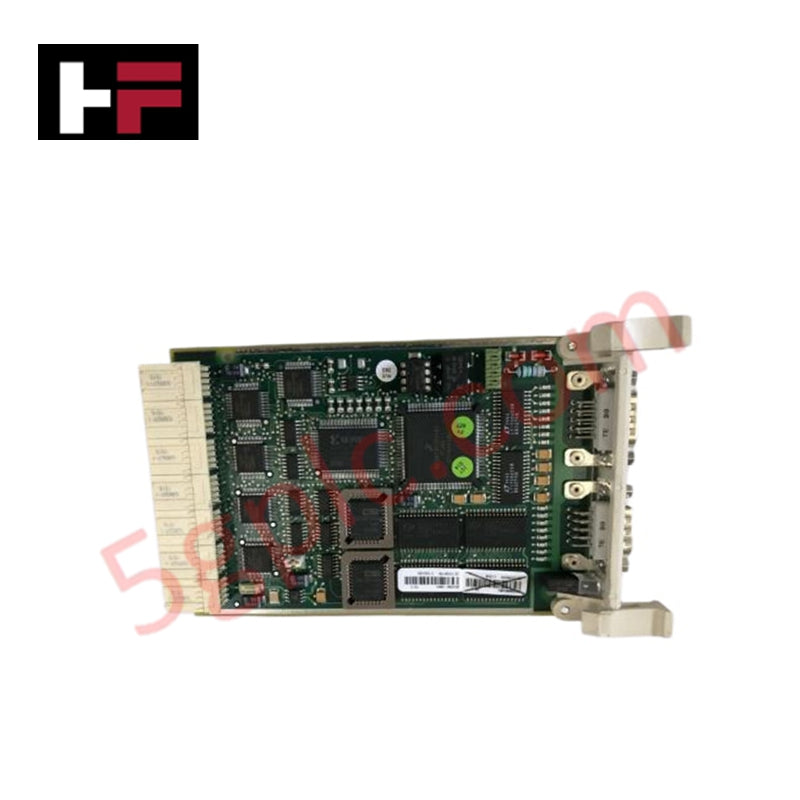

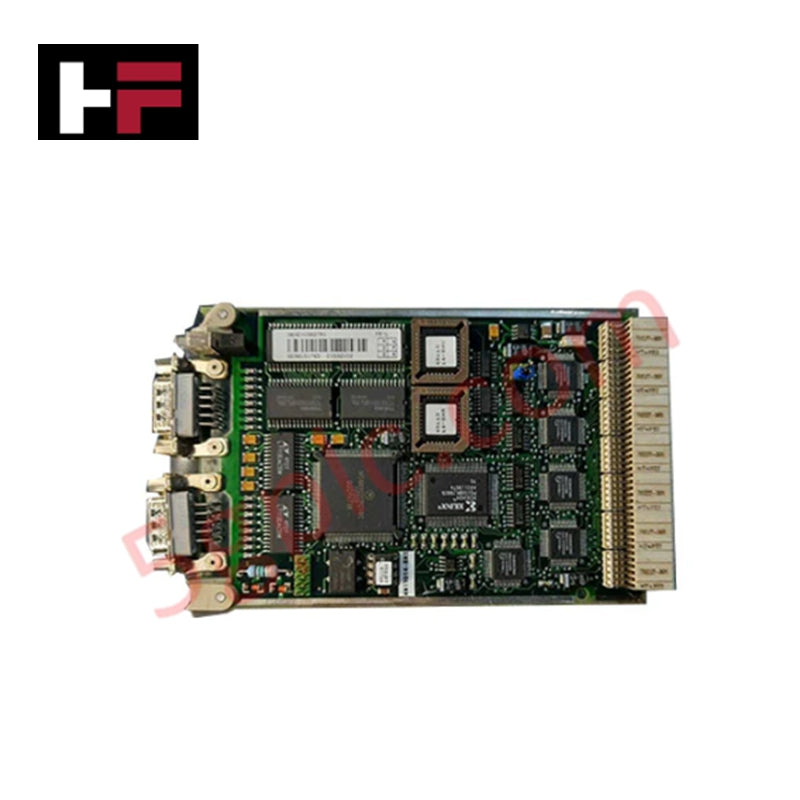

The CI840A-EA is the main intelligence unit for S800 I/O stations, managing up to 12 modules via the ModuleBus. It converts fieldbus commands into local I/O actions and reports process data to the master controller. Supporting PROFIBUS DP-V1, it enables advanced diagnostics and remote configuration, making it ideal for critical oil and gas, pharmaceutical, and power applications.

Specifications

-

Manufacturer: ABB

-

Country of Origin: Sweden

-

Model Number: CI840A-EA (3BSE041882R1)

-

Protocol: PROFIBUS DP-V1

-

Baud Rate: Auto-detecting up to 12 Mbit/s

-

I/O Capacity: Supports up to 12 S800 modules per station

-

Redundancy: Full 1:1 redundancy support when paired

-

Input Power: 24 VDC nominal

-

Current Consumption: 160 mA typical

-

Galvanic Isolation: Integrated system-to-field isolation

Features

-

Redundant Fault Tolerance: Optimized for paired operation to eliminate single points of failure in the communication backbone.

-

Smart Device Integration: Supports DP-V1 acyclic services, enabling deep diagnostic access to HART-compatible devices through the I/O rack.

-

Deterministic Performance: Provides high-speed data processing and low-latency throughput for demanding real-time control loops.

-

Dynamic Module Supervision: Automatically detects, initializes, and monitors the health of all connected analog and digital units in the cluster.

-

Live Module Replacement: Supports hot-swapping functionality, allowing for the maintenance of individual I/O modules without halting the station bus.

-

Hardened Industrial Design: Built to withstand harsh electromagnetic conditions and a wide operating temperature range in industrial cabinets.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.