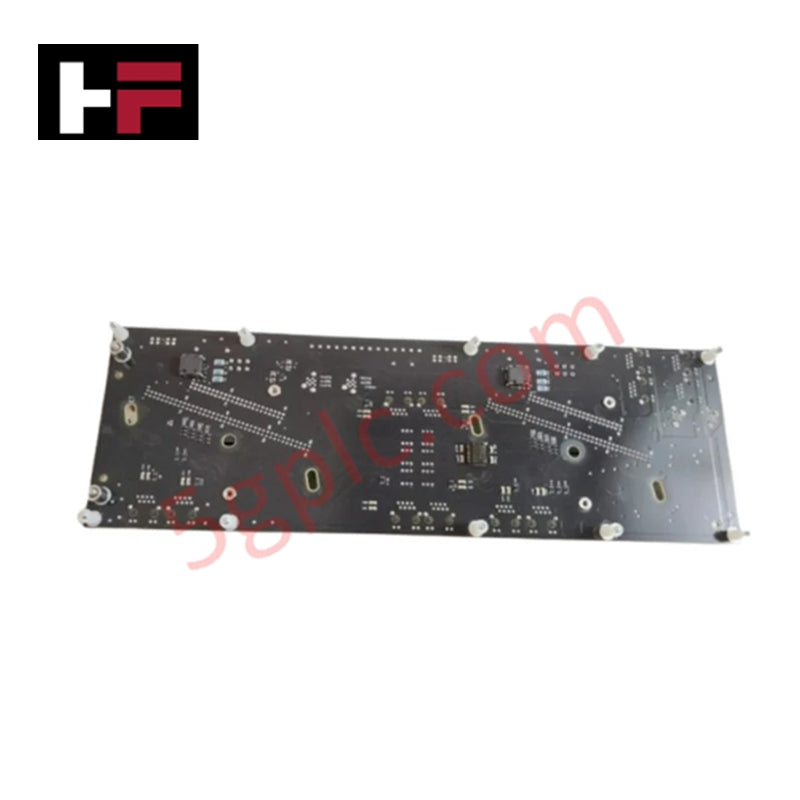

Product Details

Product Description

The Honeywell FC‑TCNT11 51307928‑176 is a redundant IOTA controller module engineered for Honeywell SC S300 Safety Manager systems. It ensures uninterrupted operation by enabling seamless failover between primary and backup controllers, making it ideal for safety‑critical applications in industries such as oil & gas, petrochemical, and pharmaceuticals.

Technical Specifications

-

Model Number: FC‑TCNT11

-

Part Number: 51307928‑176

-

Manufacturer: Honeywell

-

Type: Redundant IOTA Controller Module

-

System Compatibility: Honeywell SC S300 Safety Manager

-

Dimensions: 145.52 mm × 222.55 mm × 32 mm

-

Weight: 0.85 kg

-

Certifications: TÜV‑certified SIL3, IEC 61508 compliant

-

Condition: New, original factory product

-

Origin: USA

-

Warranty: 12 months

Key Features

-

Redundant Control: Automatic switchover between master and backup controllers without interruption

-

Real‑Time Synchronization: Maintains memory, I/O, and logic state alignment across controllers

-

Hot‑Swappable: Supports replacement without shutting down the system

-

Advanced Diagnostics: Monitors health and operational status for proactive fault detection

-

SIL3 Safety Compliance: Certified for high‑integrity safety applications including ESD, F&G, and BMS systems

-

Experion Integration: Seamlessly connects with Honeywell Experion PKS and Safety Builder platforms

Application Scenarios

-

Emergency shutdown systems (ESD)

-

Fire & Gas (F&G) detection and protection systems

-

Burner Management Systems (BMS) in power generation

-

Process safety management in chemical and petrochemical industries

FAQ

Q: Can the FC‑TCNT11 be replaced online? A: Yes, it supports hot‑swap capability, allowing replacement without system downtime.

Q: How does this module differ from FC‑SCNTO2? A: The FC‑TCNT11 focuses on redundant IOTA control, while the FC‑SCNTO2 is a processor module with enhanced logic and simulation capabilities.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.