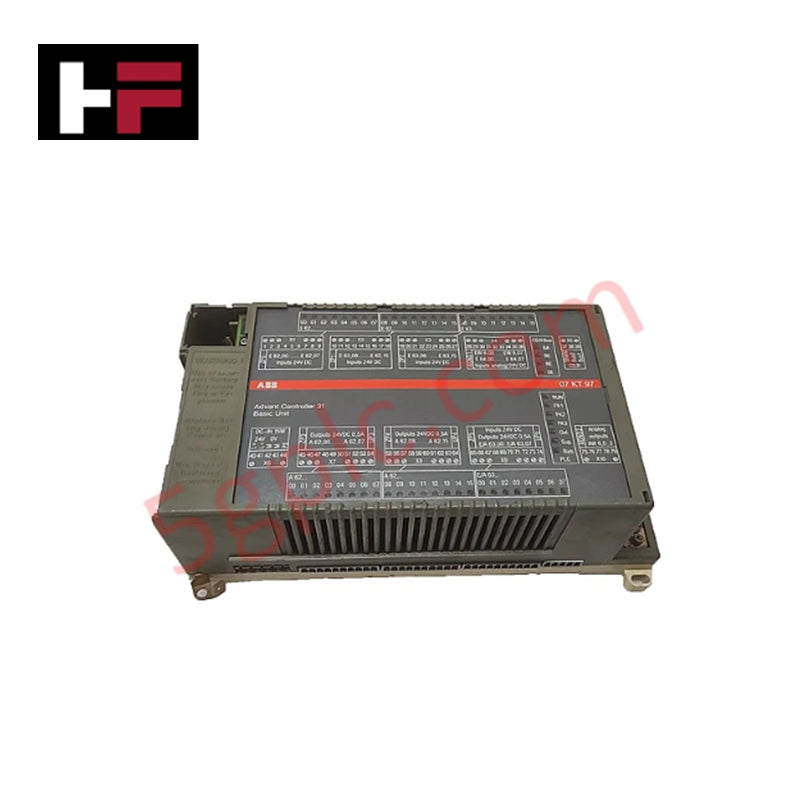

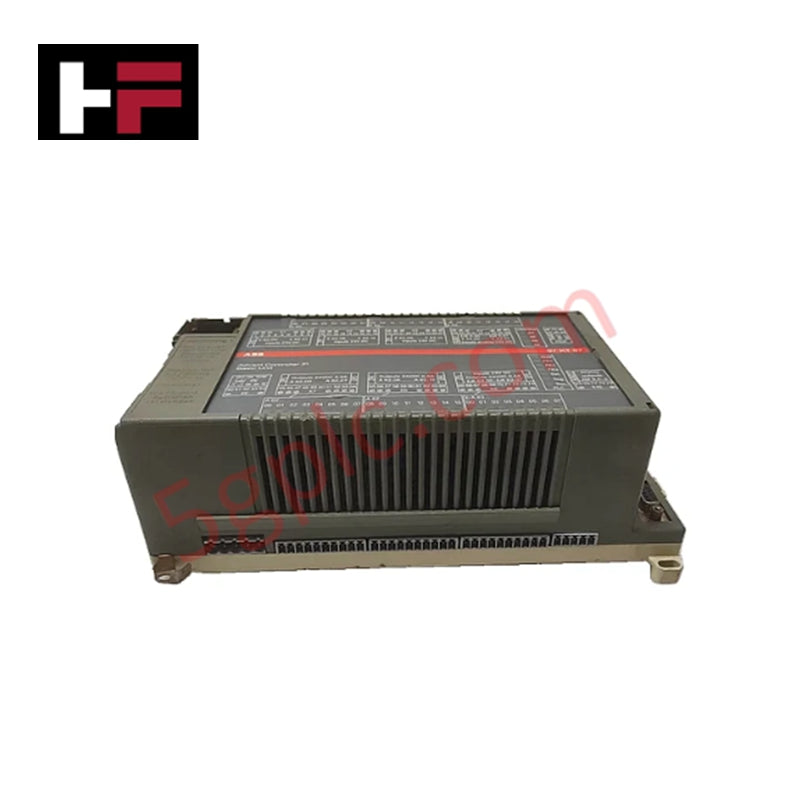

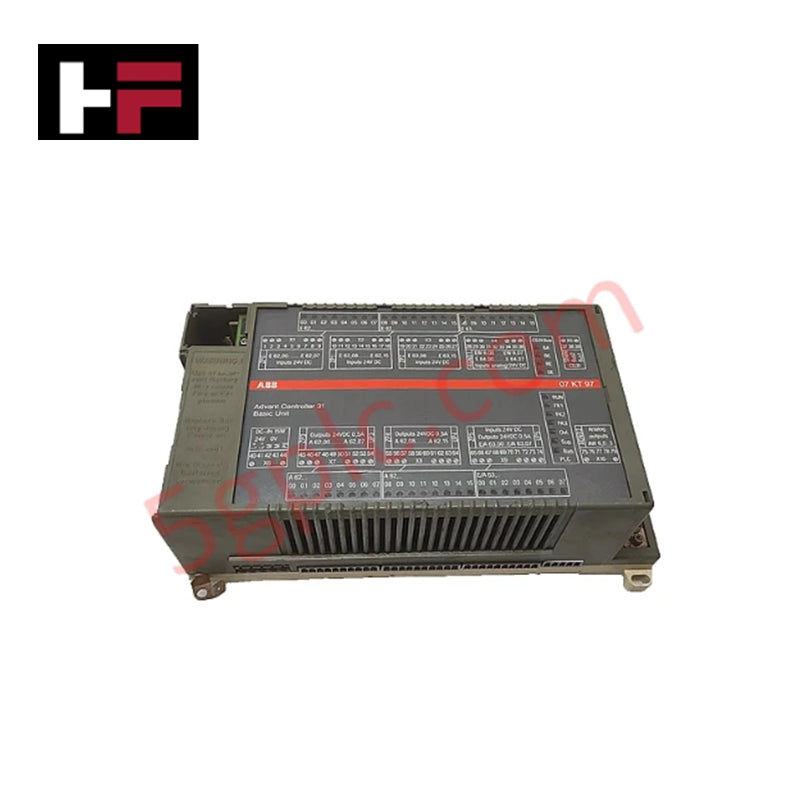

Product Details

Description

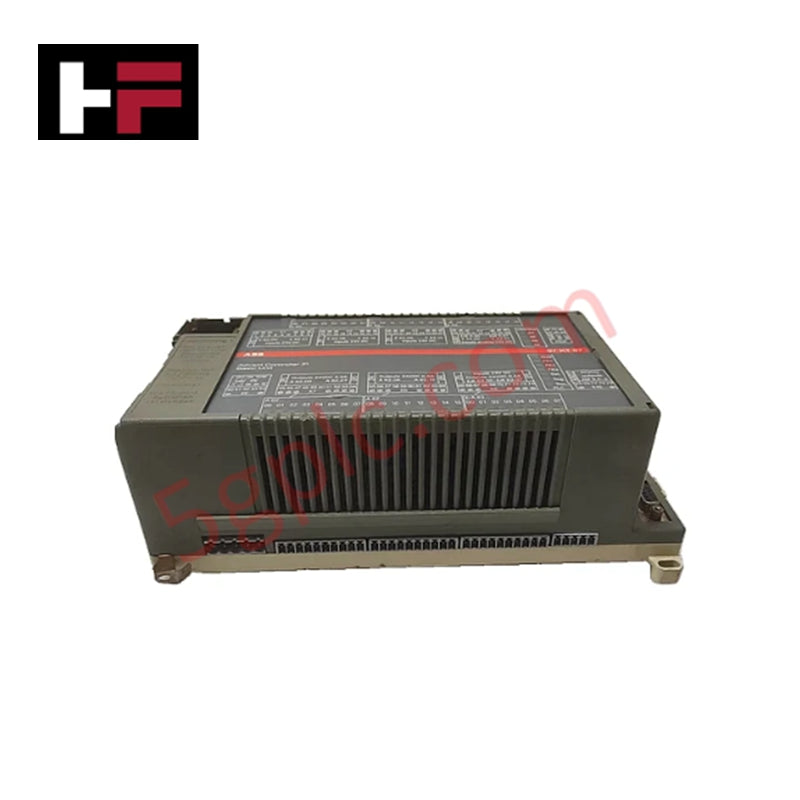

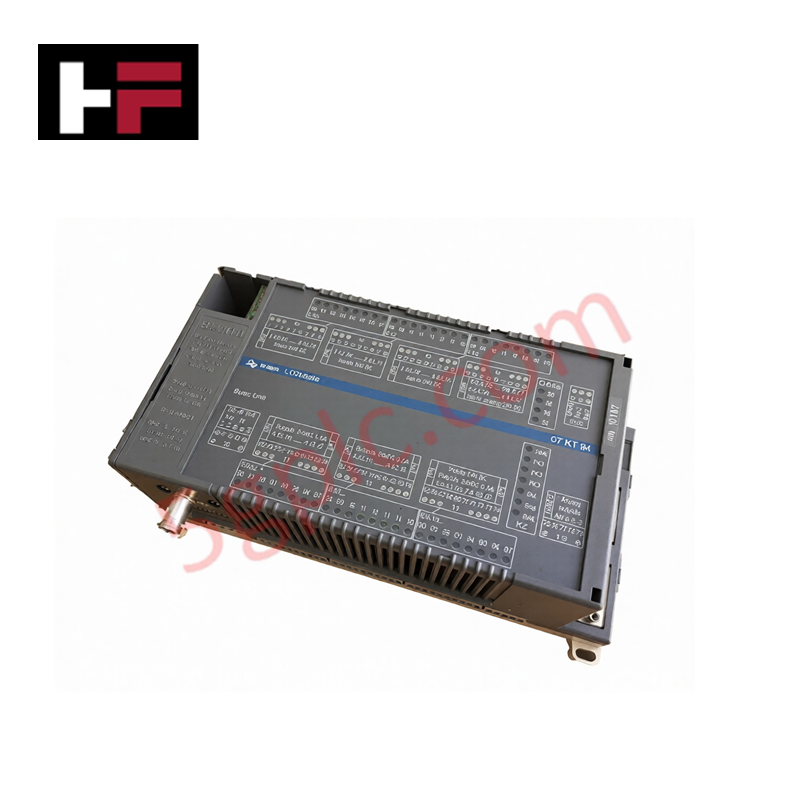

The ABB AI895 is a high-performance 8-channel analog input module designed for the S800 I/O platform. This unit is specifically engineered to interface with 4-20 mA transmitters located in hazardous environments by incorporating internal energy-limiting barriers. By removing the need for external isolation hardware, the 3BSC690086R1 optimizes cabinet space and reduces installation costs. It supports full HART digital communication pass-through, allowing for advanced device management and remote diagnostics of smart field instruments within the System 800xA architecture.

Specifications

-

Manufacturer: ABB

-

Country of Origin: Switzerland

-

Model Number: AI895

-

Order Number: 3BSC690086R1

-

Product Type: Intrinsically Safe Analog Input

-

Number of Channels: 8

-

Input Signal Range: 4 to 20 mA

-

A/D Resolution: 12-bit

-

HART Support: Bi-directional HART communication

-

Hazardous Area Suitability: Designed for connection to devices in Zone 0, 1, and 2

-

Weight: 0.3 kg

Features

-

Built-in Safety Barriers: Provides direct connectivity to field instruments in explosive atmospheres without requiring additional galvanic isolators.

-

HART Digital Integration: Facilitates seamless access to smart instrument data, including secondary variables and device health status.

-

High-Density Monitoring: Eight differential channels provide efficient use of space for complex process monitoring networks.

-

Channel Isolation: Engineered with robust galvanic isolation to prevent ground loop interference and ensure signal purity.

-

System Diagnostics: Continuously monitors for field wiring faults such as open circuits or short circuits, reporting status directly to the controller.

-

Redundant Application: Compatible with redundant configuration schemes to enhance system availability and process uptime.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.