Product Details

Description

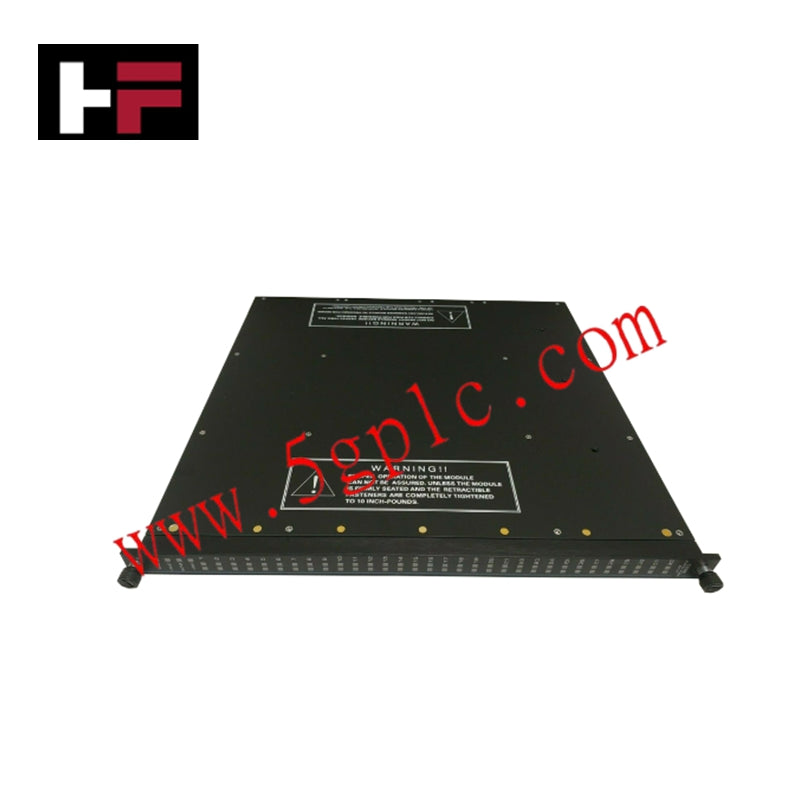

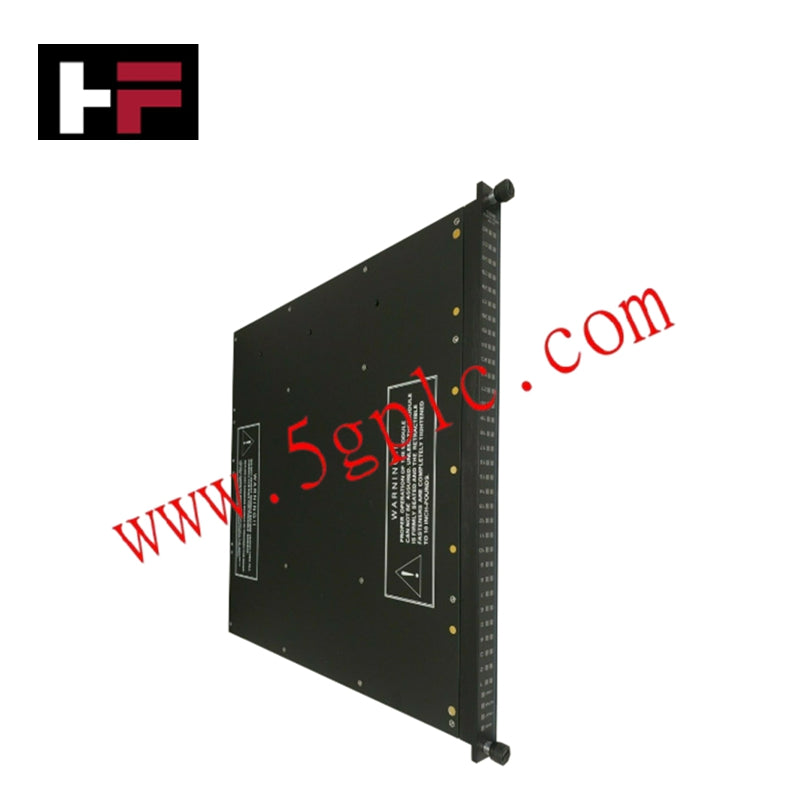

The Triconex 8111 is a high-density expansion chassis designed to increase the I/O capacity of Trident safety systems. It provides a robust backplane for housing additional functional modules while maintaining the Triple Modular Redundancy (TMR) integrity required for critical control environments.

Specifications

-

Manufacturer: Schneider Electric (Triconex).

-

Country of Origin: USA.

-

Model Number: 8111.

-

Slot Capacity: 4 module slots for I/O or communication modules.

-

Input Voltage: Dual 24 VDC power inputs for redundancy.

-

Physical Weight: Approximately 3.2 kg (7.0 lbs).

-

Dimensions: 9.0" x 5.2" x 10.5" (228 mm x 132 mm x 267 mm).

-

Mounting Options: Standard 19-inch rack or panel mounting.

-

Backplane Type: High-speed TMR communication bus.

-

Environmental Rating: -20°C to +70°C operating temperature.

Features

-

Redundant Power Distribution: Dual power connectors ensure the chassis remains operational if one power source fails.

-

Scalable Architecture: Enables simple system expansion by linking multiple chassis to a single Main Processor set.

-

Triple Modular Redundancy: Built-in backplane support for three independent communication paths between modules.

-

Hot-Swap Support: Allows for the insertion and removal of modules while the chassis is powered and online.

-

Rugged Construction: Designed to withstand high levels of vibration and shock common in industrial settings.

-

Passive Backplane: Increases system reliability by minimizing active electronic components on the chassis itself.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.