Product Details

Description

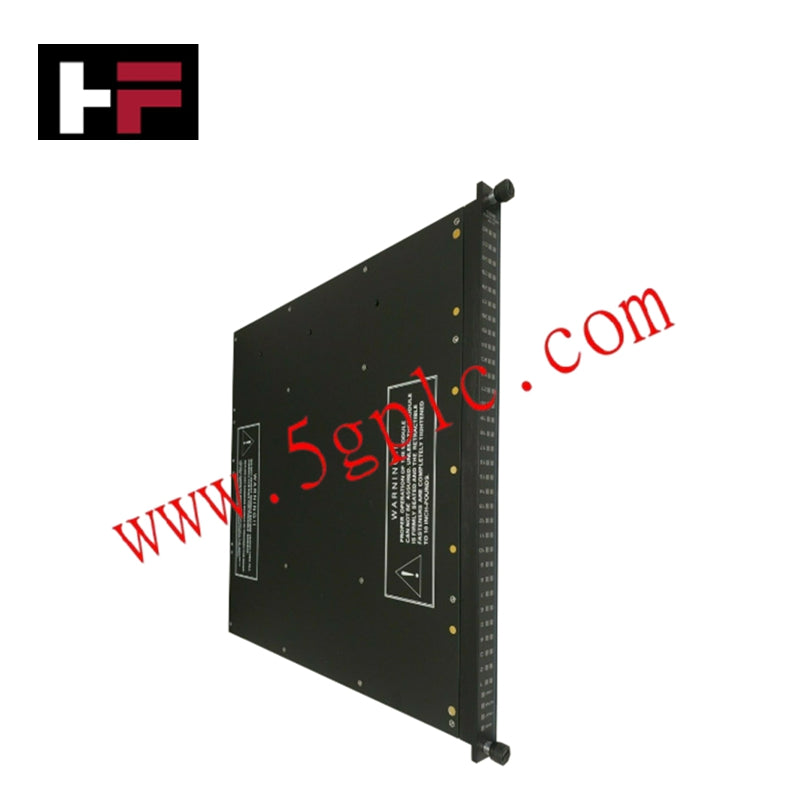

The Triconex 3510 is a high-speed pulse input module for the Trident safety system. It is specifically designed to sense frequency and pulse signals from rotating equipment, such as turbines and compressors, to provide precise speed monitoring within a Triple Modular Redundant (TMR) architecture.

Specifications

-

Manufacturer: Schneider Electric (Triconex).

-

Country of Origin: USA.

-

Model Number: 3510.

-

Input Channels: 8 independent isolated points.

-

Frequency Range: 20 Hz to 20,000 Hz.

-

Input Voltage: 1.5 V to 200 V peak-to-peak.

-

Physical Weight: Approximately 1.1 kg (2.4 lbs).

-

Dimensions: 4.5" x 1.2" x 7.3" (114 mm x 30 mm x 185 mm).

-

Update Rate: 25 milliseconds for all channels.

-

Isolation Rating: 500 VDC channel-to-channel and channel-to-logic.

-

Safety Rating: TÜV approved for SIL3 applications.

Features

-

Triple Modular Redundancy: Processes each pulse through three separate paths to ensure fault-tolerant speed measurement and safety shutdown.

-

Magnetic Pickup Support: Directly interfaces with magnetic pickup sensors and proximity probes without the need for external signal conditioning.

-

Advanced Frequency Analysis: Provides high-resolution frequency measurement to detect overspeed or underspeed conditions in real-time.

-

Hot-Swap Support: Enables module replacement during live operation, ensuring no interruption to critical turbine protection functions.

-

Internal Diagnostic Testing: Automatically verifies the integrity of the input circuitry and internal timers to detect hardware faults.

-

Status Monitoring: Features dedicated LEDs for "Active," "Fault," and individual channel activity to simplify field troubleshooting.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.