Product Details

Description

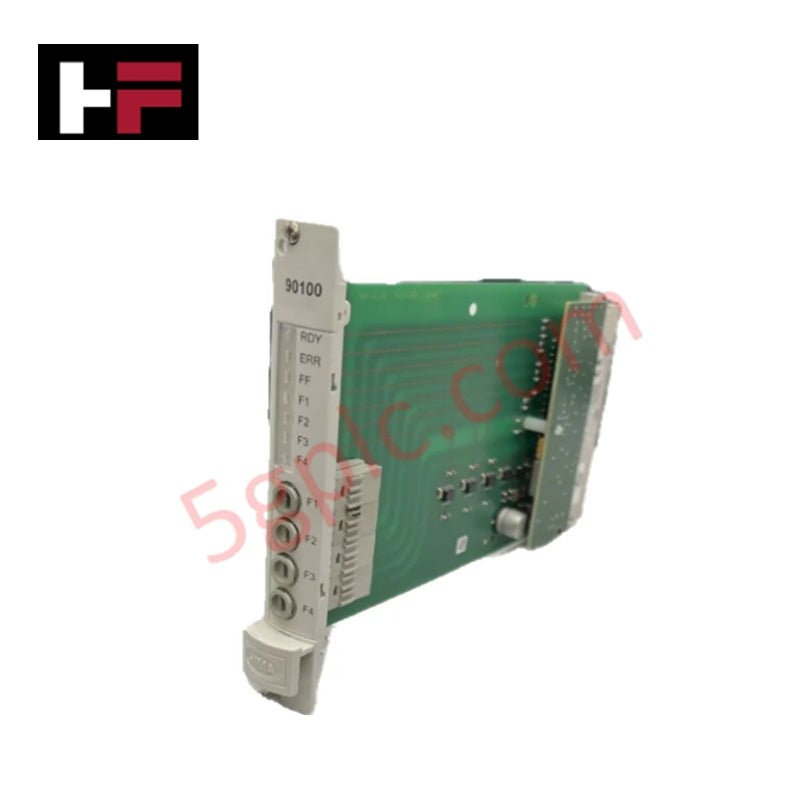

The TPM810 3BSE018151R1 is a safety module for turbine control systems, designed to monitor tachometer inputs and calculate rotational speed. It provides millisecond-range response times, ensuring immediate trip signals if safety thresholds are exceeded. The module handles speed measurement, acceleration monitoring, and zero-speed detection, often in redundant configurations to meet high Safety Integrity Level (SIL) requirements. By offloading safety tasks from the main controller, the TPM810 ensures turbine protection even during network disruptions.

Specifications

-

Manufacturer: ABB

-

Series: Symphony Melody / AC 800M

-

Model Number: TPM810

-

Order Number: 3BSE018151R1

-

Product Type: Turbine Protection Module

-

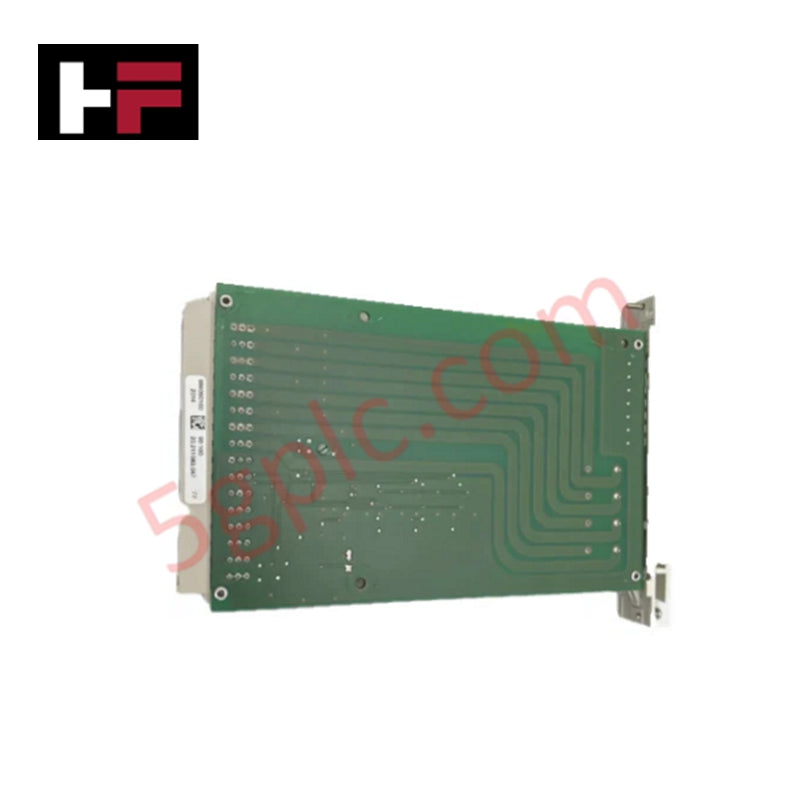

Dimensions: 186 mm x 119 mm x 45 mm

-

Weight: 0.65 kg

-

Input Type: High-speed frequency/pulse inputs (Speed Sensors)

-

Response Time: < 10 ms (Trip execution)

-

Operating Voltage: 24 V DC

-

Mounting: Standard DIN Rail via Termination Unit

-

Power Consumption: 4.5 W (Typical)

Features

-

High-Speed Overspeed Protection: Utilizes dedicated hardware processing to detect and respond to overspeed conditions with sub-10ms latency.

-

Acceleration Monitoring: Sophisticated algorithms calculate the rate of change in speed to identify potential load loss before reaching trip limits.

-

Multi-Channel Frequency Processing: Supports redundant sensor inputs to ensure fault-tolerant speed measurement and signal validation.

-

Independent Safety Operation: Operates as a localized safety controller, ensuring the turbine is brought to a safe state independently of the supervisory DCS logic.

-

Comprehensive Self-Diagnostics: Continuously monitors internal circuitry and sensor integrity, reporting faults immediately to the operator interface.

-

Fail-Safe Output Design: Features specialized relay outputs configured for fail-safe operation, ensuring a trip occurs if power or signal integrity is lost.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.