Product Details

Description

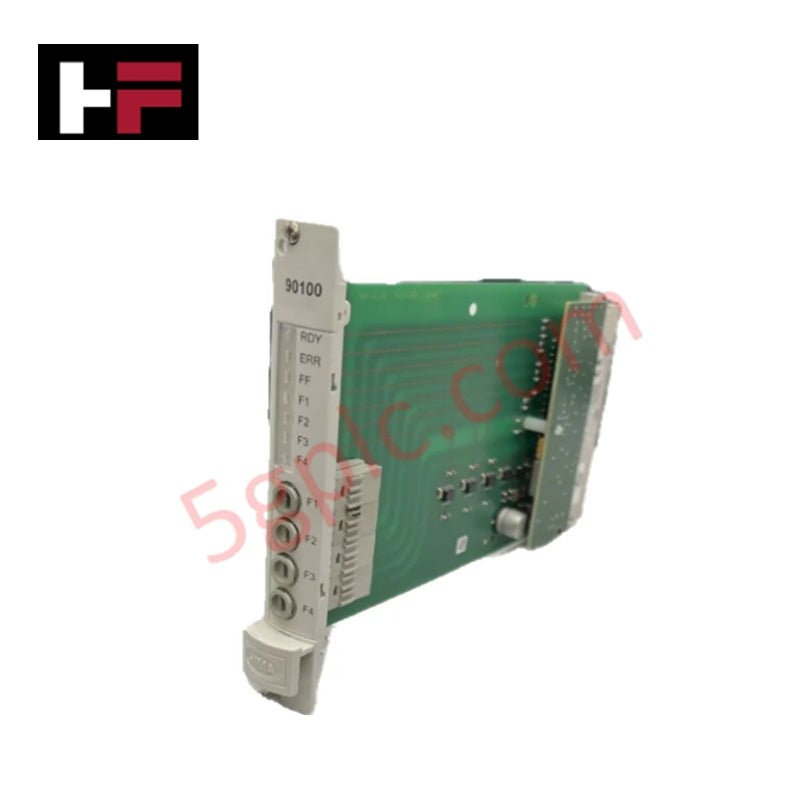

The ABB AI893 is an 8-channel analog input module for the S800 I/O system, designed to interface directly with Thermocouples and RTDs in hazardous areas. Equipped with built-in energy-limiting barriers, it allows safe sensor connections without external isolators, reducing wiring complexity and saving cabinet space. Ideal for temperature monitoring in refineries, chemical, and pharmaceutical plants.

Specifications

-

Manufacturer: ABB

-

Country of Origin: Switzerland

-

Model Number: AI839

-

Order Number: 3BSC690141R1

-

Product Type: Intrinsically Safe Temperature Input

-

Number of Channels: 8

-

Input Types: RTD (Pt100, Cu10, Ni100, Ni120) and Thermocouple (B, C, E, J, K, N, R, S, T)

-

Measurement Resolution: 15-bit plus sign

-

Hazardous Area Suitability: Designed for use with instrumentation in Zone 0, 1, and 2

-

Weight: 0.3 kg

-

Power Supply: 24V DC (via system backplane)

Features

-

Universal Sensor Support: Each channel is independently software-configurable, allowing a mix of various thermocouple and RTD types on a single module.

-

Integrated Energy Barriers: Facilitates direct field-to-module wiring for hazardous locations, eliminating the cost and complexity of external safety hardware.

-

Advanced Cold Junction Compensation: Features built-in temperature sensing for thermocouple inputs to maintain data precision across fluctuating ambient conditions.

-

Noise Immunity: Utilizes high-order digital filtering to ensure signal stability and accuracy in environments with heavy industrial electromagnetic interference.

-

Comprehensive Diagnostics: Real-time monitoring detects sensor burnout, short circuits, and internal hardware faults, alerting the System 800xA control layer immediately.

-

Hot-Swap Compatibility: Designed for rapid module replacement under system power when paired with the correct S800 Module Termination Unit (MTU).

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.