Product Details

Overview

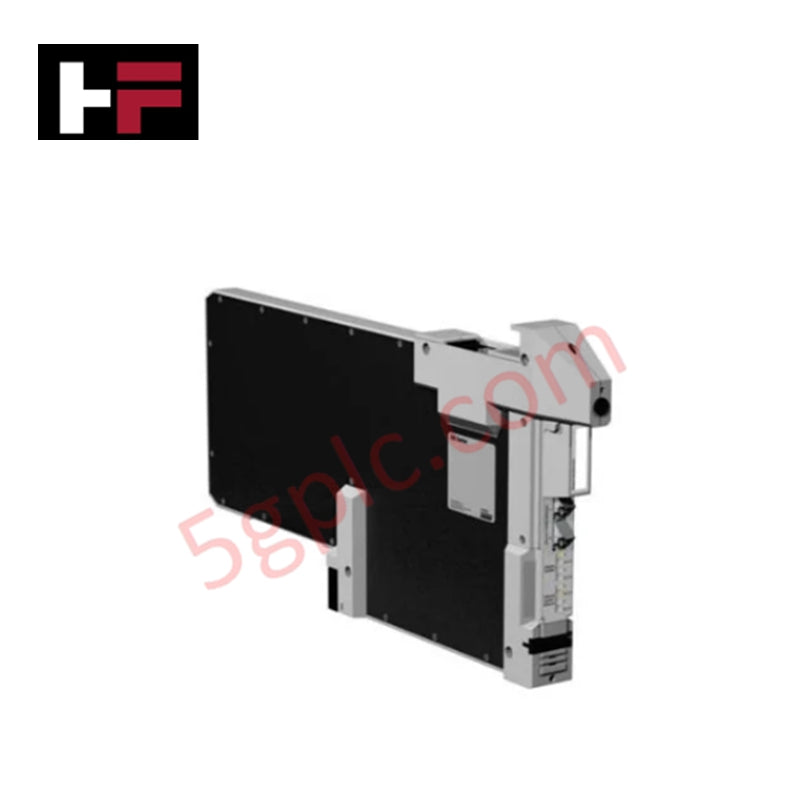

The Foxboro FBM203 P0914SV is a high-precision RTD Input Module designed for use within the Foxboro I/A Series distributed control system (DCS). This module provides eight independent RTD input channels that can accept both 2-wire and 3-wire resistance temperature detector (RTD) sensors. Each channel offers galvanic isolation to ensure accurate, noise-free signal measurement in industrial environments.

Engineered for process automation and temperature monitoring applications, the FBM203 P0914SV converts RTD sensor resistance values into digital data for precise process control and data acquisition.

Technical Specifications

-

Manufacturer: Foxboro (by Schneider Electric)

-

Model Number: FBM203 P0914SV

-

Product Series: I/A Series

-

Product Type: RTD Input Module

-

Input Channels: 8 independent, isolated RTD input channels

-

Supported RTD Types: Platinum, Nickel, and Copper RTDs

-

Input Configuration: 2-wire or 3-wire RTD connection

-

Resistance Range: 0 to 320 Ω nominal

-

Galvanic Isolation: Each input isolated from others and from ground

-

Power Supply Voltage: 24 VDC nominal

-

Operating Temperature: -40 °C to +85 °C

-

Storage Temperature: -40 °C to +100 °C

-

Dimensions: 4.5 × 11 × 11.5 cm

-

Weight: 0.32 kg

-

Mounting: DIN rail or panel mount (depending on system configuration)

Key Features

-

High-accuracy temperature measurement using RTD sensors

-

Individual channel isolation to reduce electrical interference

-

Compact design ideal for modular process control systems

-

Supports multiple RTD materials for flexible temperature applications

-

Designed for long-term reliability under extreme industrial conditions

Applications

The FBM203 P0914SV is widely used in process automation and energy systems, including:

-

Chemical and petrochemical process control

-

Oil and gas plant monitoring

-

Power generation and distribution systems

-

Pulp, paper, and food processing industries

-

Environmental and thermal regulation systems

FAQ

Q: What RTD types are compatible with FBM203 P0914SV?

A: The module supports Platinum, Nickel, and Copper RTDs in both 2-wire and 3-wire configurations.

Q: Does this module provide input isolation?

A: Yes, each input channel is galvanically isolated from all others and from system ground.

Q: What control system does it integrate with?

A: It is fully compatible with the Foxboro I/A Series DCS architecture.

Q: What is the operating voltage of this module?

A: The module operates at 24 VDC nominal input power.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.