Product Details

Product Description

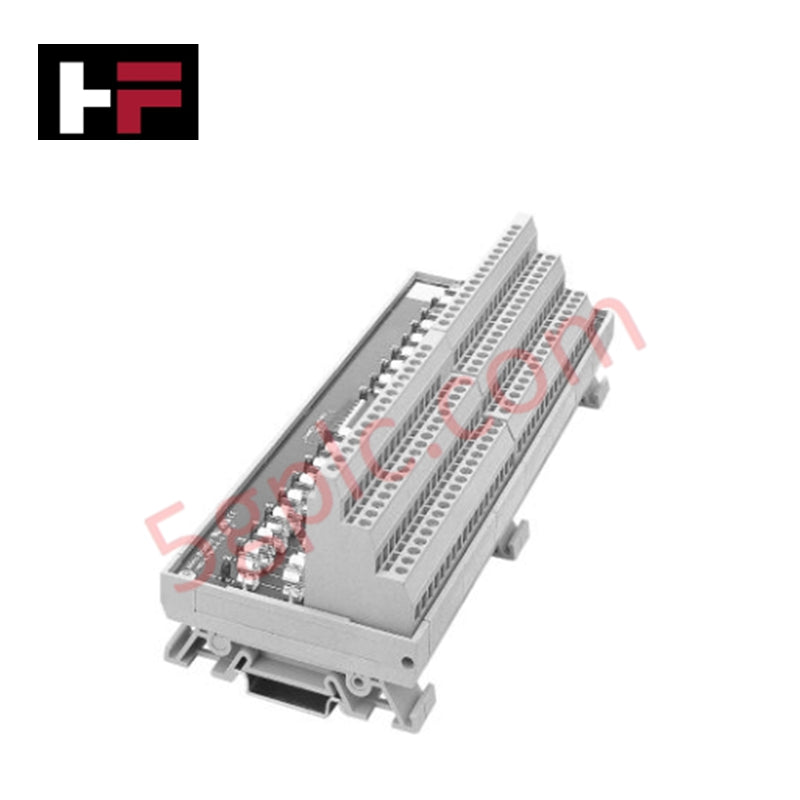

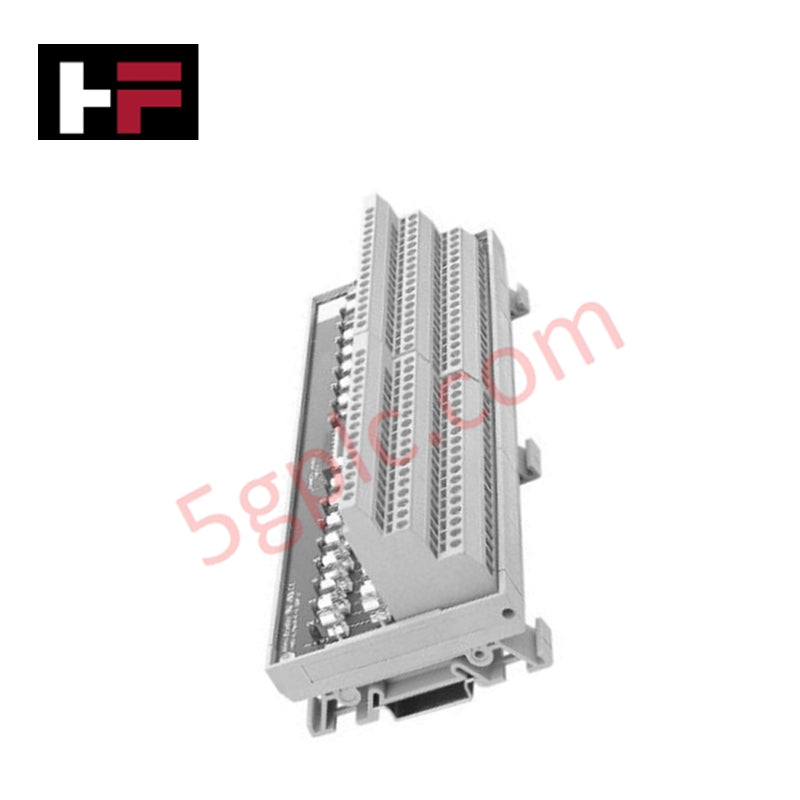

The 1746-NR4 is a 4-channel RTD and resistance input module designed for the Allen-Bradley SLC 500 series. It provides precise analog measurement of resistance temperature detectors (RTDs) and other resistance-based sensors. The module supports a 16-bit input resolution with 14-bit output, delivering accurate signal conversion and reliable process control.

Engineered for industrial environments, 1746-NR4 features 500V isolation for one minute between the field wiring and the backplane, ensuring safe and stable operation. Its flexible update time range of 17 ms to 1.2 s allows adjustment to various monitoring and control needs.

Technical Specifications

-

Manufacturer: Allen-Bradley (Rockwell Automation)

-

Model / Part Number: 1746-NR4

-

Series: SLC 500

-

Module Type: RTD/Resistance Analog Input

-

Input Channels: 4

-

Input Resolution: 16-bit

-

Output Resolution: 14-bit

-

Backplane Current: 50 mA

-

Bandwidth: 2.62 – 65.5 Hz

-

Update Time: 17 ms – 1.2 s

-

Step Response Time: 60 ms (input), 2.5 ms (output)

-

Operating Isolation: 500 V DC for 1 minute

-

Operating Temperature: 0 – 60 °C

-

Storage Temperature: -40 – 85 °C

-

Module Compatibility: SLC 500 chassis

Key Features

-

High-precision 16-bit input conversion

-

Supports RTD sensors and resistance-based devices

-

Wide bandwidth and flexible update timing

-

Safe 500V isolation for industrial environments

-

Compact SLC 500 form factor for easy installation

Applications

-

Industrial temperature monitoring with RTDs

-

Resistance-based process measurement

-

SLC 500 series analog control systems

-

Data acquisition in automated control networks

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.