Product Details

Description

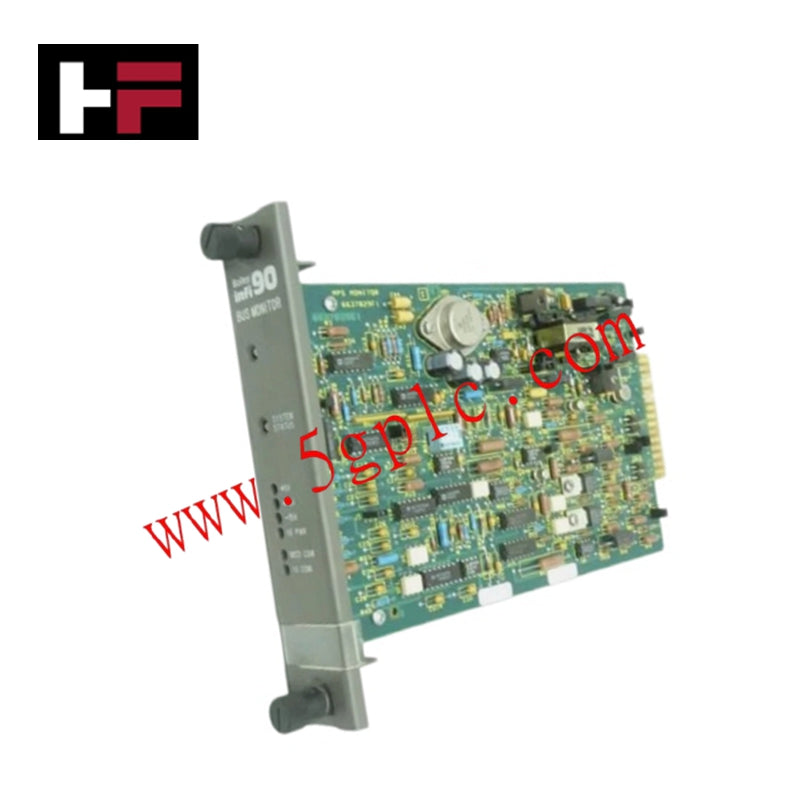

The ABB 6637830G1 is a specialized diagnostic instrument designed for real-time surveillance of the INFI 90 and Symphony Plus communication backplanes. This Bus Monitor module functions as a critical auditing tool, providing engineers and maintenance personnel with deep visibility into the Control Bus and Slave Expander Bus traffic. Its primary role is to intercept and analyze data packets without interfering with active control processes, making it essential for identifying communication bottlenecks, protocol errors, or hardware collisions within a module mounting unit. By monitoring signal integrity at the physical and data link layers, the 6637830G1 ensures that the deterministic nature of the Distributed Control System (DCS) remains uncompromised during complex plant operations.

Specifications

-

Brand: ABB Bailey

-

Model Number: 6637830G1

-

Product Series: INFI 90 / Symphony Plus

-

Functional Role: System Bus Analysis and Monitoring

-

Bus Compatibility: Harmony Control Bus / Slave Expander Bus

-

Mounting: Standard INFI 90 Module Mounting Unit (MMU)

-

Power Source: Powered via the system backplane (+5 VDC)

-

Interface: Front-panel diagnostic ports for external analyzer connection

-

Operating Temperature: 0 to 70 degrees Celsius

-

Storage Temperature: -40 to 85 degrees Celsius

Features

-

Passive Monitoring Architecture: Observes all backplane traffic in a non-intrusive manner, ensuring that primary control logic execution is never delayed.

-

Real-Time Fault Detection: Identifies intermittent communication failures and protocol timing violations that can lead to system-wide resets.

-

Streamlined Troubleshooting: Minimizes plant downtime by pinpointing the specific module or bus segment responsible for data integrity issues.

-

High-Speed Data Capture: Engineered to keep pace with the high-frequency packet rates characteristic of the INFI 90 Cnet and local bus environments.

-

Modular Integration: Standard card-edge design allows for rapid insertion into any vacant slot within the Harmony rack for immediate diagnostic sessions.

-

Industrial Hardening: Built to the rigorous standards of power generation facilities, providing reliable operation in high-EMI environments.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.