Product Details

Overview

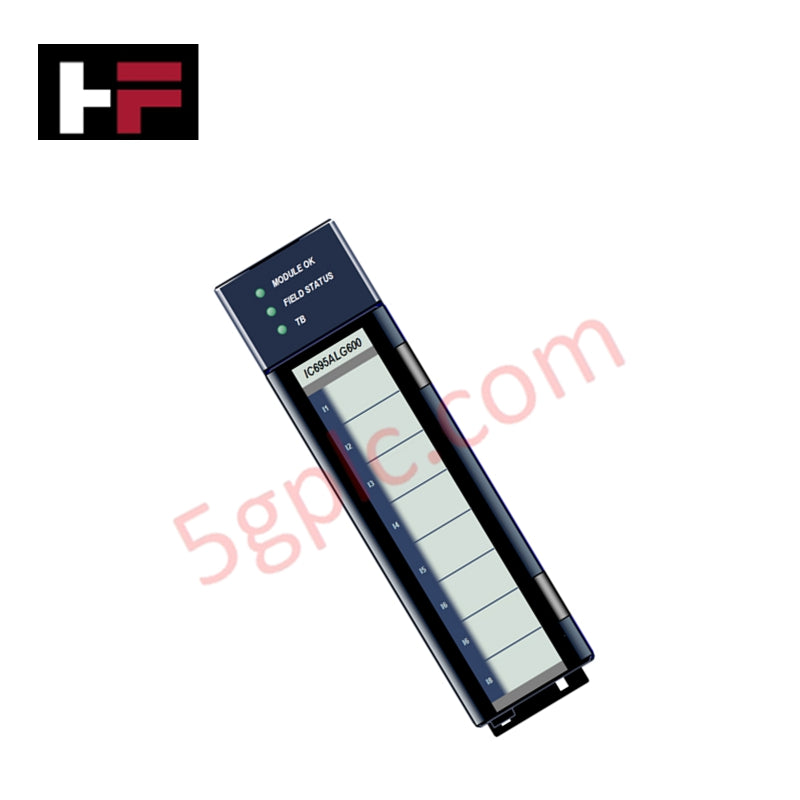

The IC695ALG600 is a versatile analog input module designed for the GE Fanuc PACSystems RX3i series. It provides eight configurable input channels capable of handling voltage, current, thermocouple, RTD, and resistance signals. Each channel can be individually set up for a wide range of industrial sensors, making it suitable for precise process monitoring, temperature measurement, and general-purpose analog data acquisition. Built-in LED indicators provide instant feedback on module and field status, while its low power consumption ensures efficient operation.

Technical Specifications

General

-

Model / Part Number: IC695ALG600

-

Series: PACSystems RX3i

-

Input Channels: 8 analog inputs, organized into 2 groups of 4

-

Supported Input Types:

-

Voltage

-

Current

-

Thermocouples (B, C, E, J, K, N, R, S, T)

-

RTDs (PT385 / 3916, N618 / 672, NiFe518, CU426)

-

Resistance (0–250 Ω, 500 Ω, 1000 Ω, 2000 Ω, 3000 Ω, 4000 Ω)

Electrical Characteristics

-

Current Input Ranges: 0–20 mA, 4–20 mA, +20 mA

-

Voltage Input Ranges: +50 mV, +150 mV, 0–5 V, 1–5 V, 0–10 V, +10 V

-

Power Requirements: 400 mA max @ 5V, 350 mA max @ 3.3V

-

CPU Memory Usage: 40 bytes for channel input data, 40 bytes for diagnostics, 4 bytes for module status

-

Maximum Power Dissipation: 5.4 Watts

Indicators

-

One green LED for module status

-

Bi-color green/yellow LED for field status

-

Bi-color red/green LED for terminal block status

Environmental & Mechanical

-

Operating Temperature: 0°C to 60°C (typical for RX3i modules)

-

Module Weight: Lightweight, fits standard RX3i backplane

Applications

The IC695ALG600 is ideal for temperature and process monitoring, industrial sensor integration, and general-purpose analog data acquisition. It can be used in control systems requiring accurate thermocouple and RTD measurements, voltage or current monitoring, or resistance-based sensor inputs.

FAQ / Common Questions

Q: How many input channels does this module support?

A: The IC695ALG600 provides 8 configurable analog input channels.

Q: What types of sensors can be connected?

A: Voltage, current, thermocouples, RTDs, and resistive sensors are supported.

Q: Does it have visual status indicators?

A: Yes, it features module, field, and terminal block LEDs for quick diagnostics.

Q: How much CPU memory does it use?

A: 40 bytes for channel data, 40 bytes for diagnostics, and 4 bytes for module status.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.