Product Details

Overview

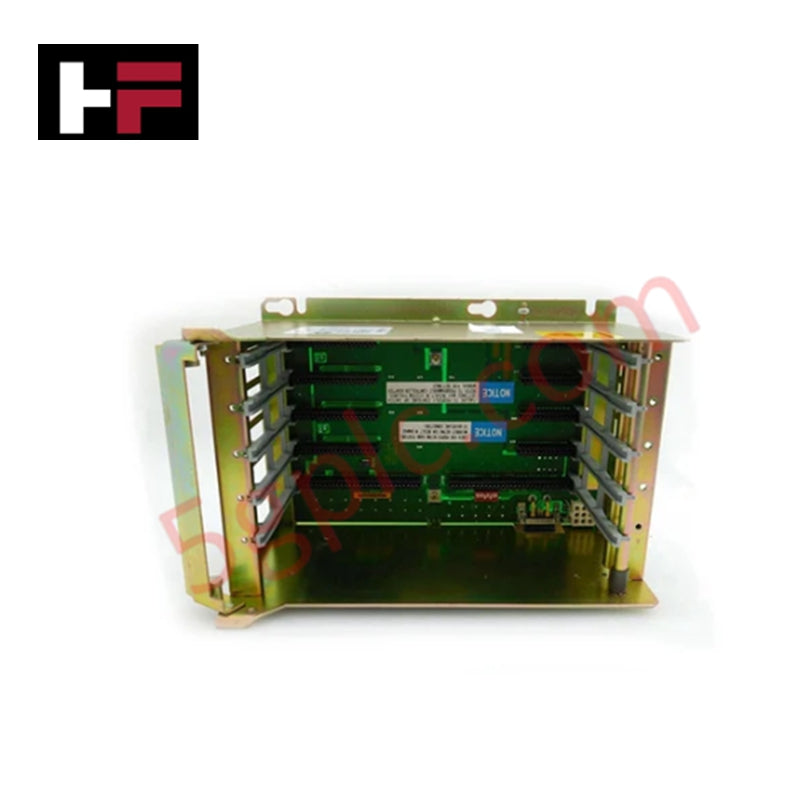

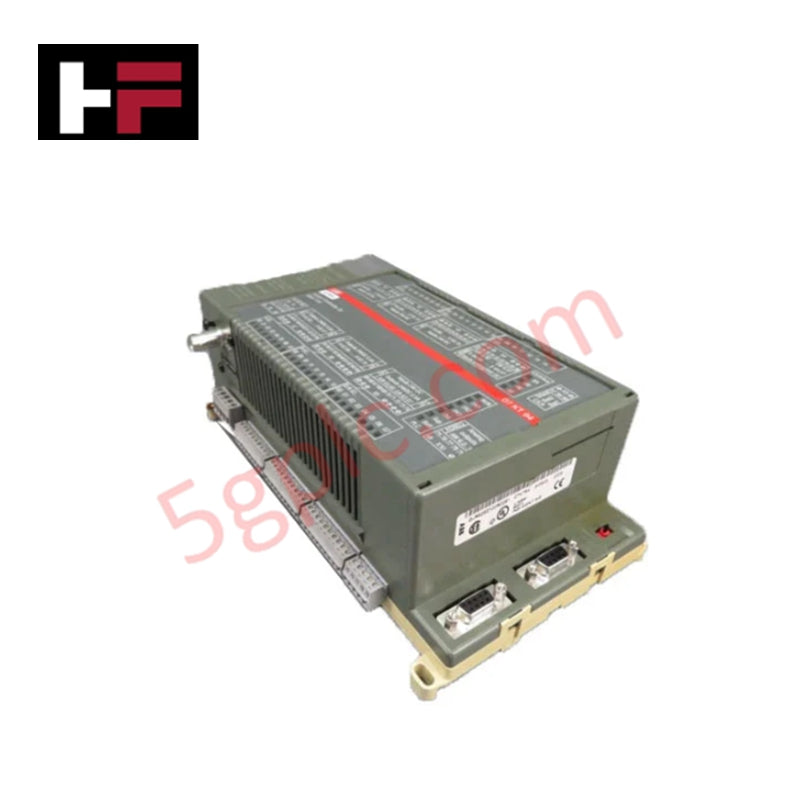

The Allen-Bradley 1771-A3B1 is a universal I/O chassis engineered for industrial automation and control systems. With support for up to 12 I/O modules, this chassis offers a scalable and reliable foundation for PLC-5 and distributed control networks. Its open-style, panel-mounted design simplifies wiring access and integration in control panels.

Key Features

-

Module Capacity: Accommodates 12 I/O modules for flexible configuration

-

Mounting Type: Designed for panel-mount installations

-

Electrical Rating: Maximum backplane current of 24 A at 5 V DC

-

Durability: Withstands operating shock of 15 g and non-operating shock of 30 g

-

Vibration Resistance: Rated at 2 g for frequencies between 10–500 Hz

-

Open Chassis Design: Facilitates easy module installation and maintenance

Technical Specifications

Manufacturer: Rockwell Automation

Brand: Allen-Bradley

Part Number: 1771-A3B1

Module Type: Universal I/O Chassis

Number of I/O Slots: 12

Mount Type: Panel Mount

Enclosure Type: Open Style

Electrical & Environmental

-

Maximum Backplane Current: 24 A @ 5 V DC

-

Operating Temperature: 0–60°C (32–140°F)

-

Relative Humidity: 5–95%, non-condensing

-

Vibration: 2 g (10–500 Hz)

-

Operating Shock: 15 g

-

Non-Operating Shock: 30 g

Physical Dimensions & Weight

-

Dimensions: 483 × 339 × 221 mm (19 × 12.4 × 7.6 in)

-

Weight: 5.9 kg (13 lbs)

Applications

-

PLC-5 series and distributed control systems

-

Large-scale industrial automation requiring multiple I/O modules

-

Manufacturing process control

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.