Product Details

Description

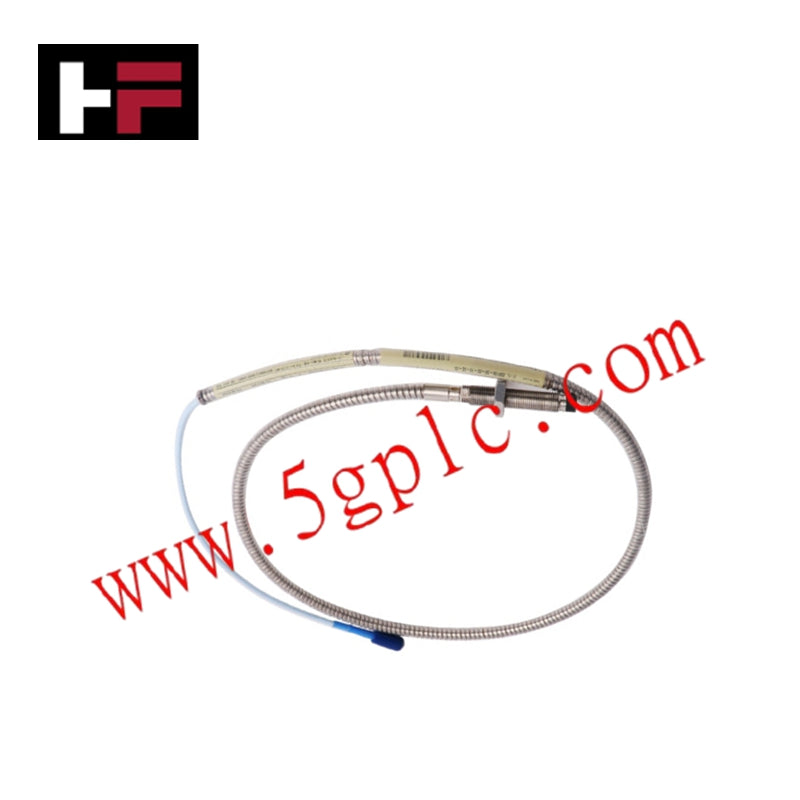

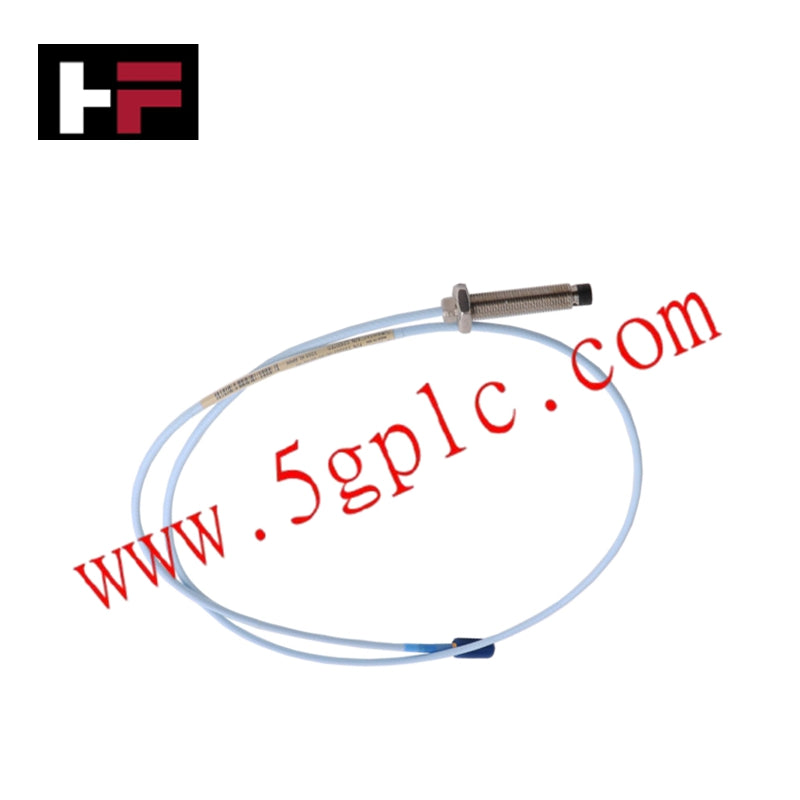

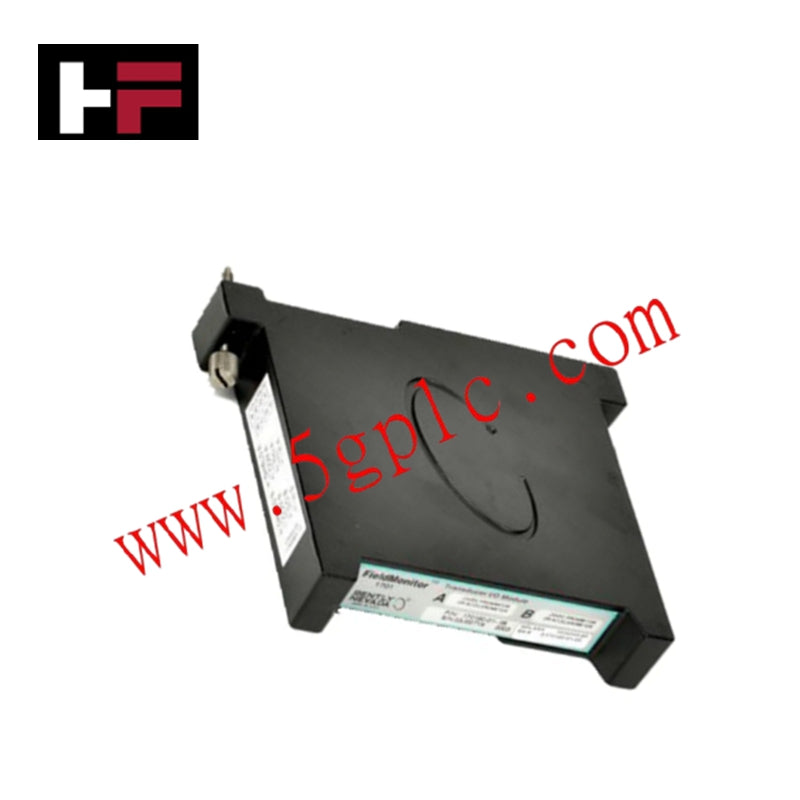

The Bently Nevada 79532-01 82369-01 4‑Wire RTD Input Terminal Module is engineered to provide precise temperature monitoring by supporting 4‑wire RTD sensors, ensuring reliable signal transmission and integration with industrial monitoring systems.

Specifications

-

Manufacturer: Bently Nevada

-

Model: 79532-01 / 82369-01

-

Function: RTD input terminal module for temperature monitoring

-

Sensor Type: Supports platinum RTD sensors (PT100/PT1000)

-

Configuration: 4‑wire input to minimize lead resistance errors

-

Input Channels: Multiple RTD sensor connections

-

Compatibility: Integrated with Bently Nevada monitoring platforms

-

Power Supply: 24V DC ±10%

-

Dimensions: Approx. 3.0 cm × 12 cm × 10 cm

-

Weight: 0.40 kg

-

Durability: Built for continuous operation in harsh environments

Features

-

Precise Measurement: 4‑wire RTD input ensures accurate temperature readings

-

Reliable Monitoring: Provides stable signal transmission for industrial applications

-

System Integration: Seamless compatibility with Bently Nevada monitoring systems

-

Industrial Durability: Designed for robust operation in demanding conditions

-

Compact Build: Lightweight and space-efficient for easy installation

-

Enhanced Diagnostics: Supports predictive maintenance with accurate temperature data

-

Flexible Application: Suitable for turbines, compressors, and other rotating machinery

-

Maintenance Friendly: Simplifies installation and replacement processes

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.