Product Details

Overview

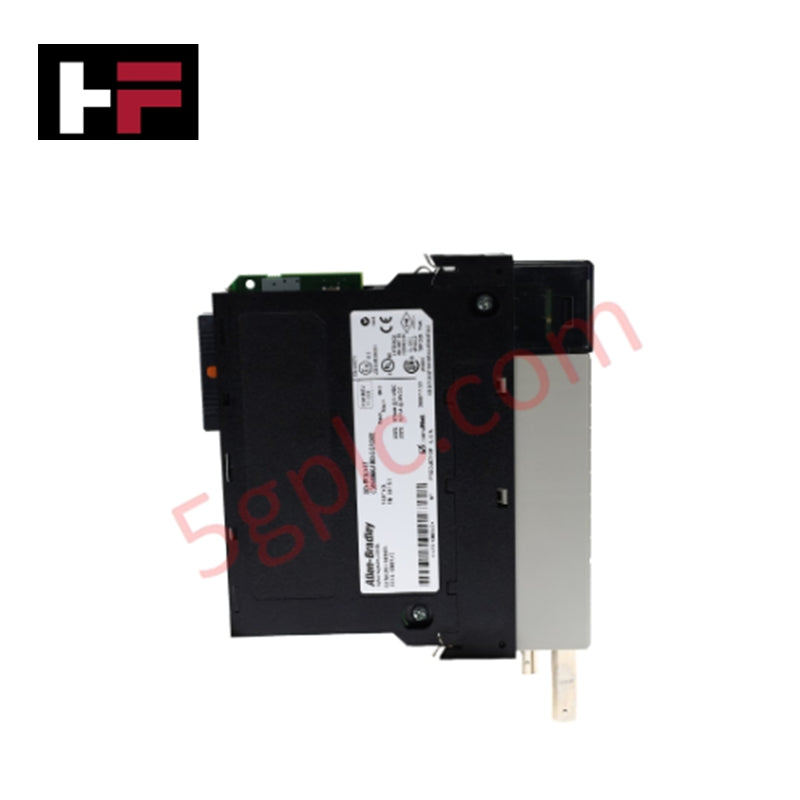

The Allen-Bradley 1756-PH75 ControlLogix power supply ensures reliable operation of ControlLogix modules with a 90-143V DC input and 13A output. It's designed to maintain system integrity and enable safe shutdown in the event of a power failure.

Key Features

• Input Voltage: 90-143V DC

• Output Current: 13A

• Temperature Range: 0°C to 60°C (operating), -40°C to 85°C (storage)

• Humidity: 95% RH max

• Vibration Resistance: 2 m/s² acceleration, 500 Hz frequency

Specifications

• Manufacturer: Allen-Bradley

• Part Number: 1756-PH75

• Power Supply Type: DC Input Power Supply for ControlLogix

• Operating Temperature: 0°C to 60°C

• Storage Temperature: -40°C to 85°C

• Vibration: 2 m/s², 500 Hz

• Dimensions: 7.5 x 6 x 3 inches

• Weight: 2.25 lbs (1.02 kg)

Applications

The 1756-PH75 is ideal for powering ControlLogix systems in industrial automation, process control, and machine management applications. It supports reliable and consistent power delivery for various ControlLogix modules.

Advantages

• Reliable Power: Ensures stable operation of ControlLogix modules

• System Protection: Signals imminent power failure for safe system shutdown

• Compact & Efficient: Space-saving design with high output capacity

• Environmentally Resistant: Vibration and temperature-resistant for industrial settings

FAQ

Q1: What is the power supply voltage range for the 1756-PH75?

A1: The 1756-PH75 supports an input voltage range of 90-143V DC, ensuring flexibility in various power environments.

Q2: Can the 1756-PH75 be used in harsh environments?

A2: Yes, the 1756-PH75 can be ordered with a conformal coating option for additional protection against environmental factors such as dust, moisture, and corrosion.

Q3: Does the 1756-PH75 offer any features to protect against power failure?

A3: Yes, the 1756-PH75 includes a signaling feature that warns modules in the chassis of an impending voltage failure, enabling an orderly shutdown.

Q4: What is the operating temperature range for the 1756-PH75?

A4: The 1756-PH75 operates within a temperature range of 0°C to 60°C (32°F to 140°F), making it suitable for most industrial environments.

Q5: Is the 1756-PH75 suitable for use in vibration-prone applications?

A5: Yes, the 1756-PH75 is designed to withstand up to 2 m/s² of acceleration and 500 Hz of vibration frequency, making it ideal for use in dynamic environments.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.