Product Details

Overview

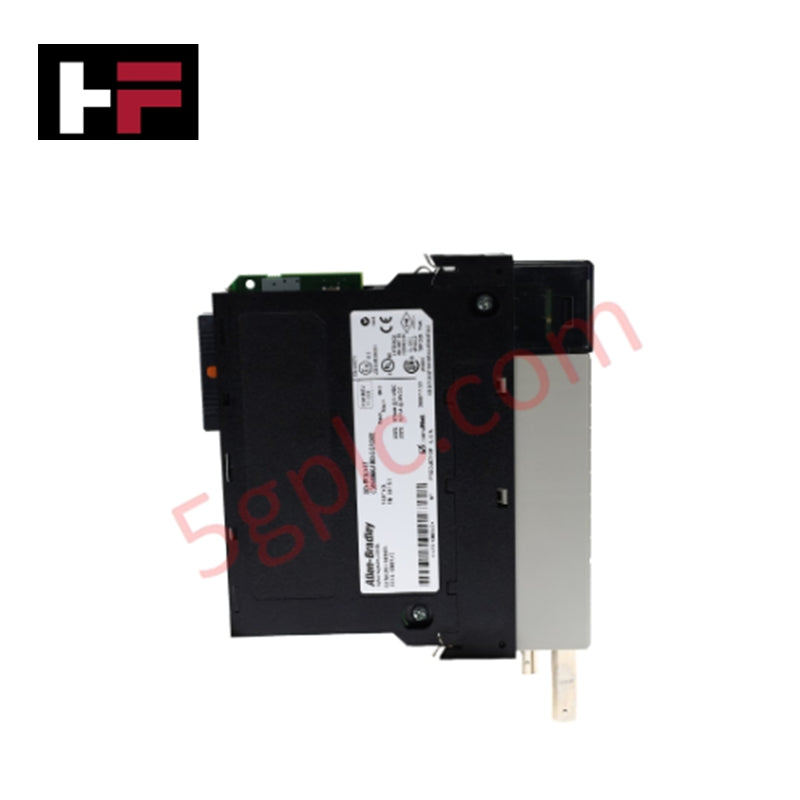

The Allen-Bradley 1747-L552 is a high-performance controller from the SLC 500 series, designed for efficient logic control and data processing in complex industrial automation systems. With 32K words of user memory, this unit has been a reliable choice for various control applications, ensuring precise, stable performance under demanding conditions.

As of March 31, 2024, the 1747-L552 has been officially discontinued, and no longer available for direct purchase.

Key Features

• Memory: 32K words of user memory to handle a variety of control tasks

• Processor: High-performance processor for fast and accurate execution of control logic

• Multiple I/O Interfaces: Supports digital, analog, and communication interfaces for versatile integration in automation systems

• Reliability: Known for robust performance and stability in industrial settings

• Programming & Maintenance: Compatible with various programming languages and provides built-in diagnostic tools for easier troubleshooting

Technical Specifications

• User Memory: 32K words

• Processor: High-performance processor optimized for control logic execution

• Supported Interfaces: Digital, analog, and communication I/O interfaces

• Programming Languages Supported: Ladder Logic, Function Block Diagram, and Structured Text

• Diagnostic Tools: Built-in diagnostic and debugging functions to streamline maintenance

• Mounting Type: Panel mounting

• Power Supply: Requires external power supply for operation (not included)

• Environmental Conditions:

-

Operating Temperature: 0 to 60°C (32 to 140°F)

-

Storage Temperature: -40 to 85°C (-40 to 185°F)

-

Relative Humidity: 5 to 95%, non-condensing

Applications

The 1747-L552 controller is widely used in industries requiring fast, reliable control of processes. Typical applications include:

• Manufacturing Automation: For controlling machines, conveyors, and assembly lines

• Process Control: Ideal for managing continuous processes in industries like food processing, chemicals, and pharmaceuticals

• Energy Management: For monitoring and controlling electrical systems

• Building Automation: Used in HVAC systems and environmental control systems

Advantages

• Scalability: Easily expandable to meet the growing demands of automation systems

• Flexibility: Multiple I/O interfaces allow integration with a wide range of devices and systems

• High Reliability: Ensures consistent performance even under varying environmental conditions

• Ease of Use: Supports multiple programming tools and has built-in diagnostics for easier maintenance and troubleshooting

FAQ

Q1: Is the 1747-L552 still available for purchase?

A1: No, as of March 31, 2024, the 1747-L552 has been discontinued and is no longer available from Allen-Bradley.

Q2: What is the memory capacity of the 1747-L552 controller?

A2: The 1747-L552 has 32K words of user memory, providing ample capacity for control and data processing needs in industrial applications.

Q3: Can I use the 1747-L552 with other Allen-Bradley controllers?

A3: Yes, the 1747-L552 is part of the SLC 500 series and is fully compatible with other modules and controllers within the SLC 500 family, offering a high degree of flexibility in system configuration.

Q4: What programming languages are supported?

A4: The 1747-L552 supports Ladder Logic, Function Block Diagram, and Structured Text, making it suitable for a variety of programming approaches.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.