Product Details

Overview

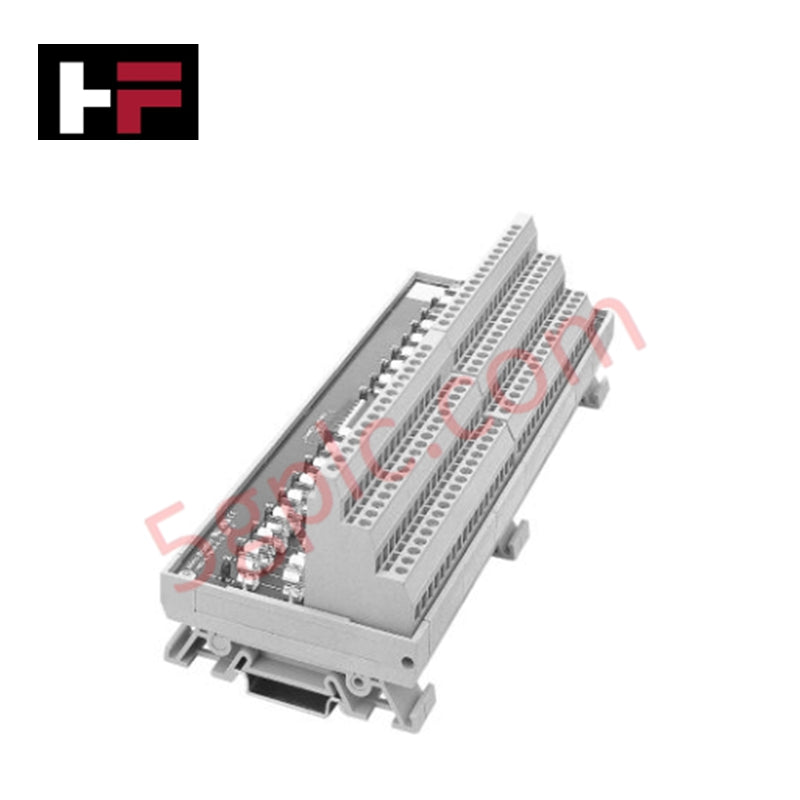

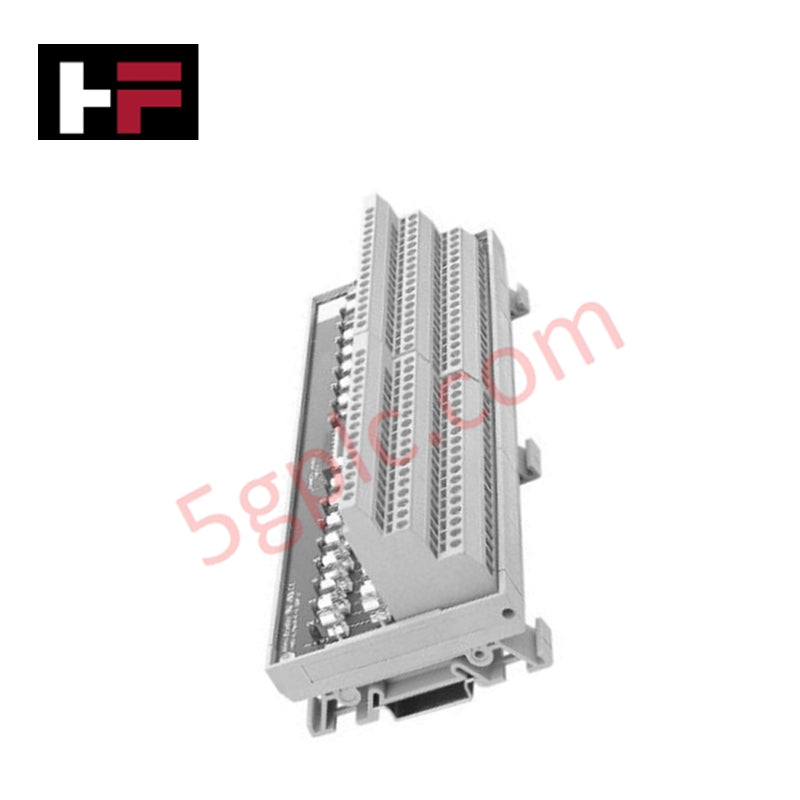

The Allen-Bradley 1762-L24BWA is a MicroLogix 1200 series programmable controller designed for compact industrial automation applications. It provides 14 digital inputs and 10 relay outputs, supporting reliable control in a wide range of environments. Built-in power flexibility and robust design ensure stable operation in both standard and challenging conditions.

Technical Specifications

Power & Electrical

-

Model: 1762-L24BWA

-

Input Power: 120/240V AC

-

Power Supply Range: 100 to 240V AC (-15% to +10%) at 47–63 Hz

-

Power Consumption: 70 VA

-

Input Circuit Type: 24V DC sink/source

-

Output Circuit Type: Relay

-

Relay Operation Shock Tolerance: 1.5G

I/O Configuration

-

Digital Inputs: 14 points

-

Digital Outputs: 10 points

Environmental Ratings

-

Operating Temperature: 0°C to 55°C (+32°F to +131°F) ambient

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Relative Humidity: 5% to 95%, non-condensing

-

Vibration Tolerance: 10–500 Hz, 5G, 0.030 in peak-to-peak for 2 hours per axis

Physical Dimensions

-

Length: 11 cm

-

Width: 9 cm

-

Height: 8.7 cm

-

Weight: 0.91 kg

Applications

The 1762-L24BWA is ideal for small-to-medium process control systems, machine automation, and remote I/O operations where compact size, moderate I/O counts, and reliable AC power operation are required.

FAQ

Q: What voltage range does the controller support?

A: It operates from 100 to 240V AC with standard industrial frequency (47–63 Hz).

Q: How many I/O points are available?

A: The controller provides 14 digital inputs and 10 relay outputs.

Q: Can it operate in high-humidity environments?

A: Yes, it supports 5%–95% relative humidity in non-condensing conditions.

Q: Is it suitable for vibration-prone environments?

A: Yes, it tolerates up to 5G vibration and 0.03 in peak-to-peak displacement.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.