Product Details

Description

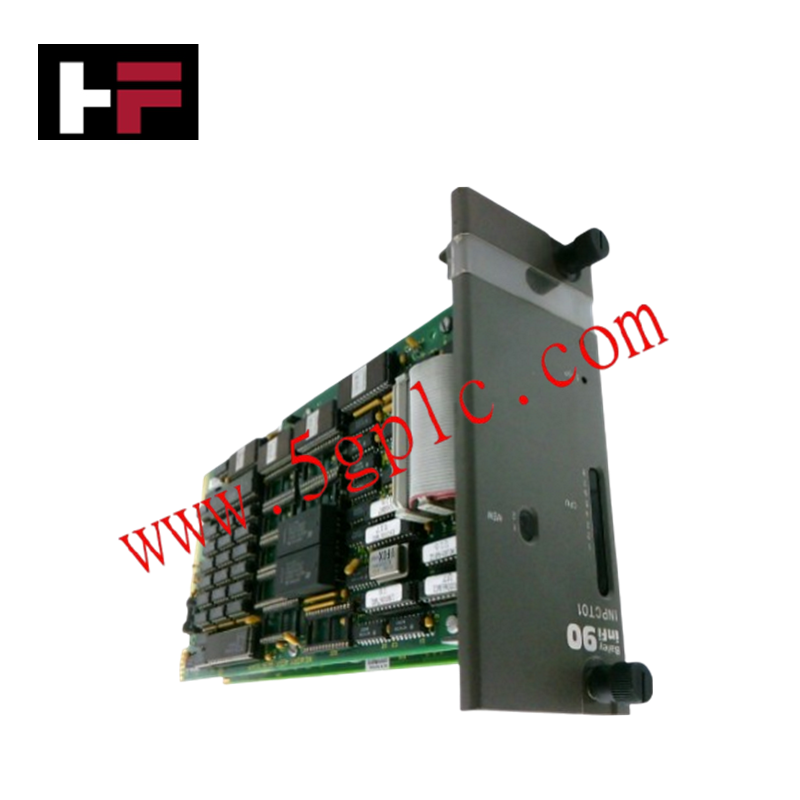

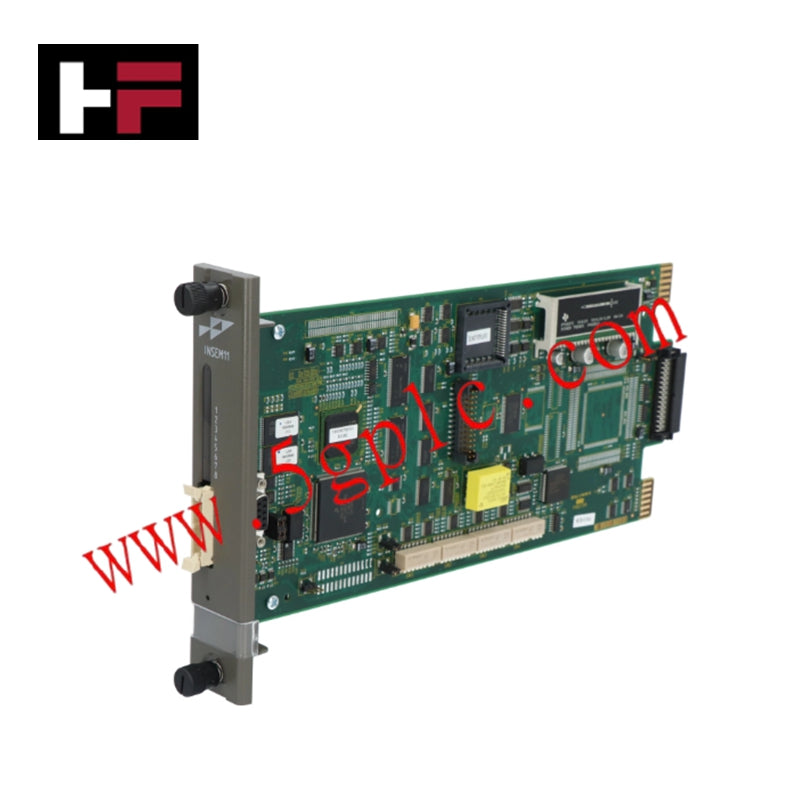

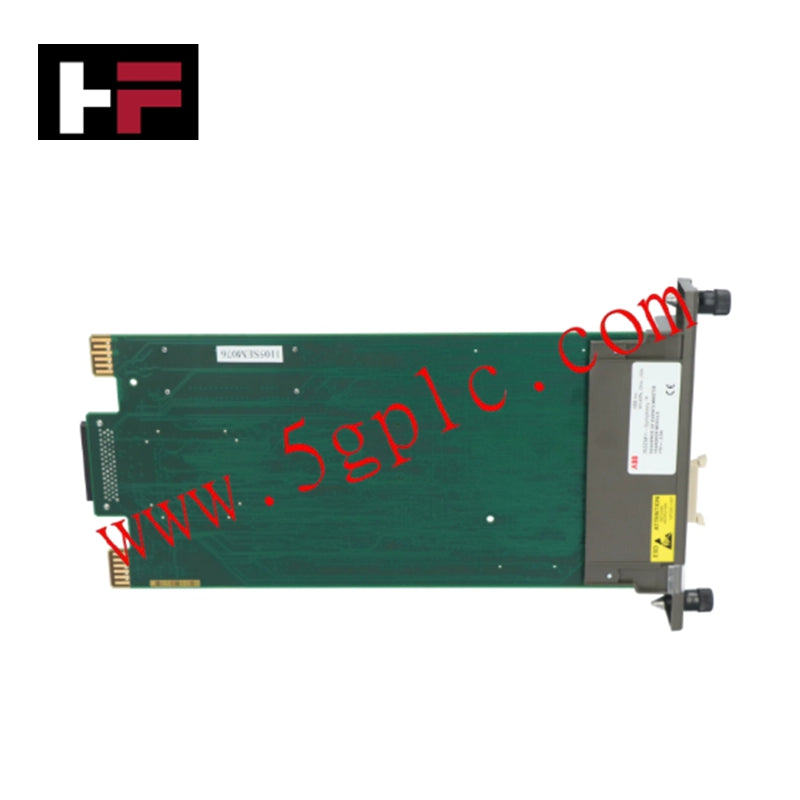

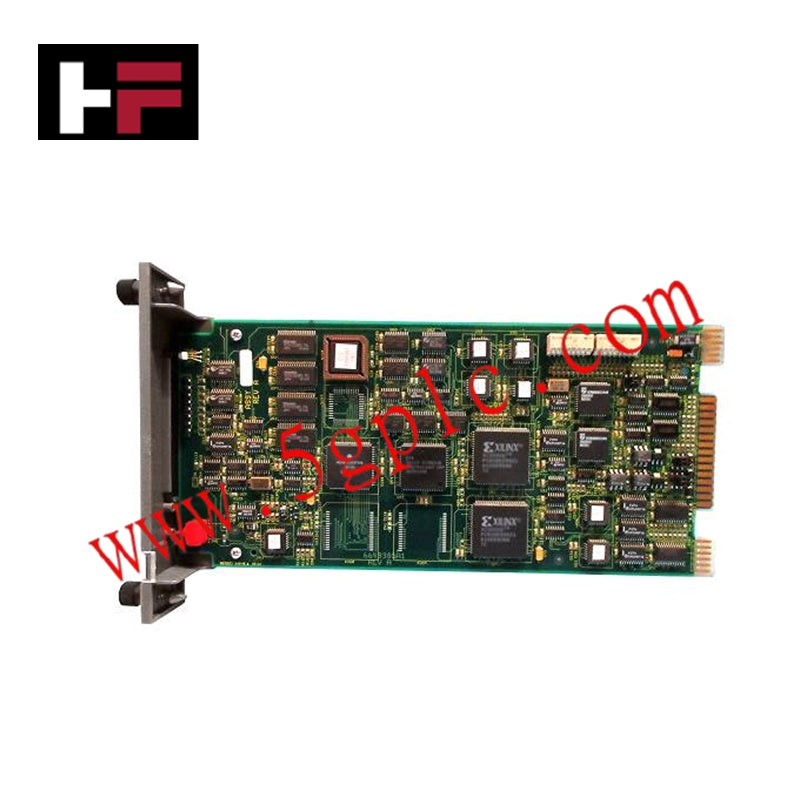

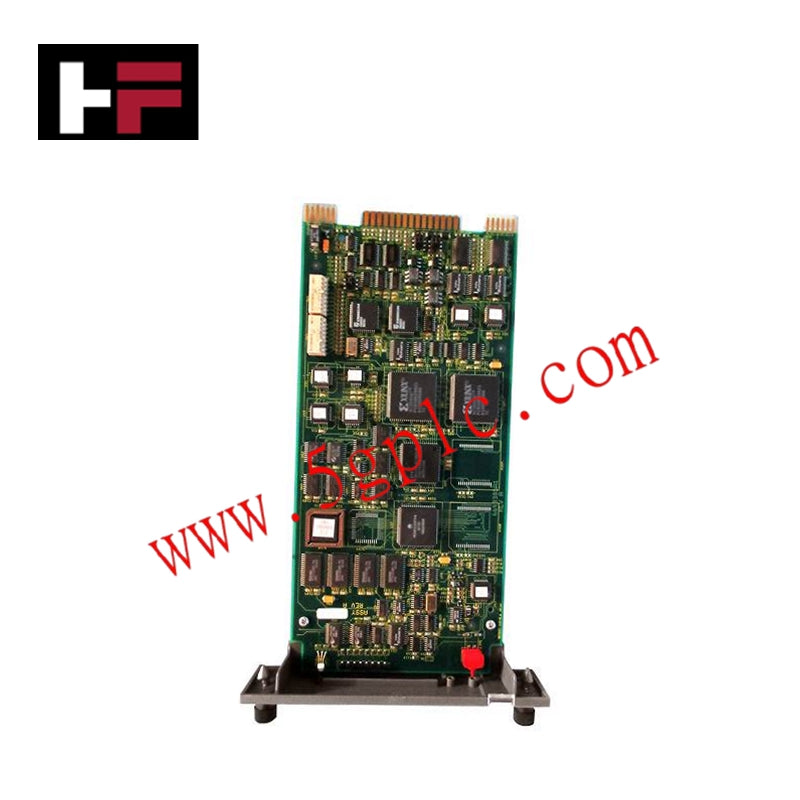

The ABB INPCT01 is a communication gateway for Bailey Infi 90 and Network 90 systems, bridging the Plant Loop and external systems like host computers or workstations. It translates proprietary protocols into serial data, enabling data acquisition, monitoring, and configuration management. By acting as a secure buffer, the INPCT01 ensures that administrative data requests don't disrupt real-time control operations.

Specifications

-

Brand: ABB Bailey

-

Model Number: INPCT01

-

Product Type: Plant Loop to Computer Transfer Module

-

Series: Infi 90 / Network 90

-

Network Interface: Plant Loop (Communication Ring)

-

Host Interface: RS-232-C / RS-485 Serial Connectivity

-

Net Weight: 0.63 kg (1.39 lbs)

-

Mounting: Standard Module Mounting Unit (MMU)

Features

-

Bi-Directional Data Bridge: Facilitates the seamless flow of process variables to host systems and configuration commands back to the DCS.

-

Deterministic Traffic Isolation: Dedicated hardware architecture protects the Plant Loop from external network noise and irregular data polling.

-

Legacy System Support: Vital for maintaining connectivity between original Network 90 architectures and modern HMI workstations.

-

Onboard Diagnostic Monitoring: Front-panel indicators provide real-time status of loop communication activity and module hardware health.

-

High-Reliability Construction: Engineered for continuous 24/7 operation in demanding industrial control room environments.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.