Product Details

Description

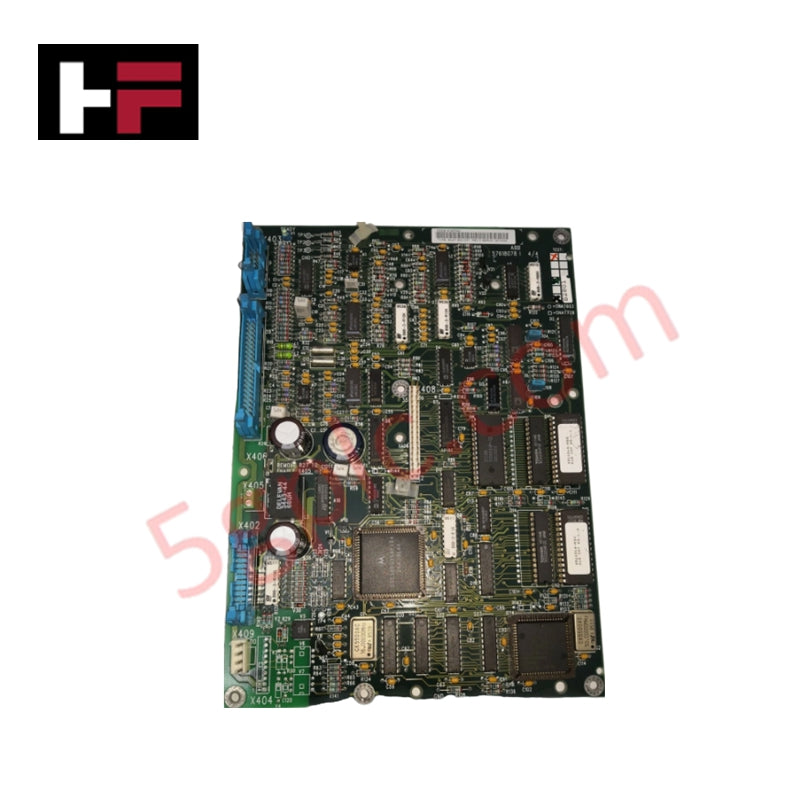

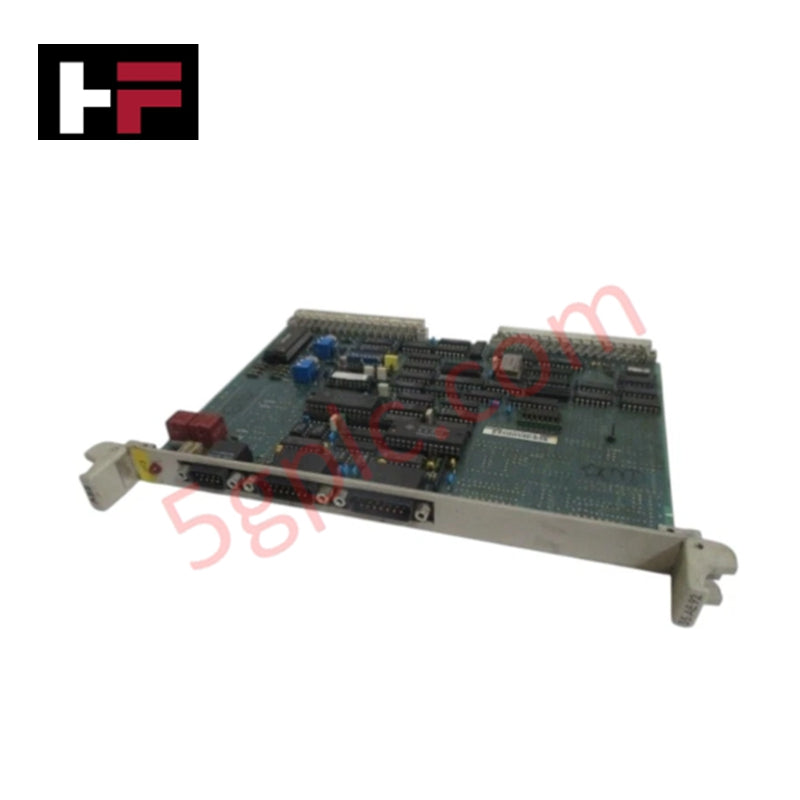

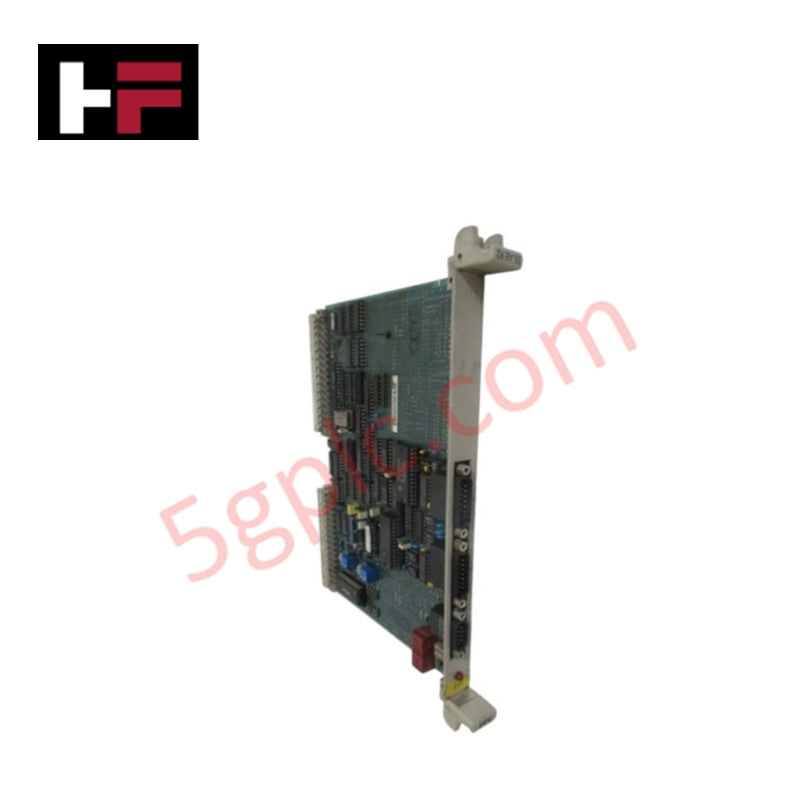

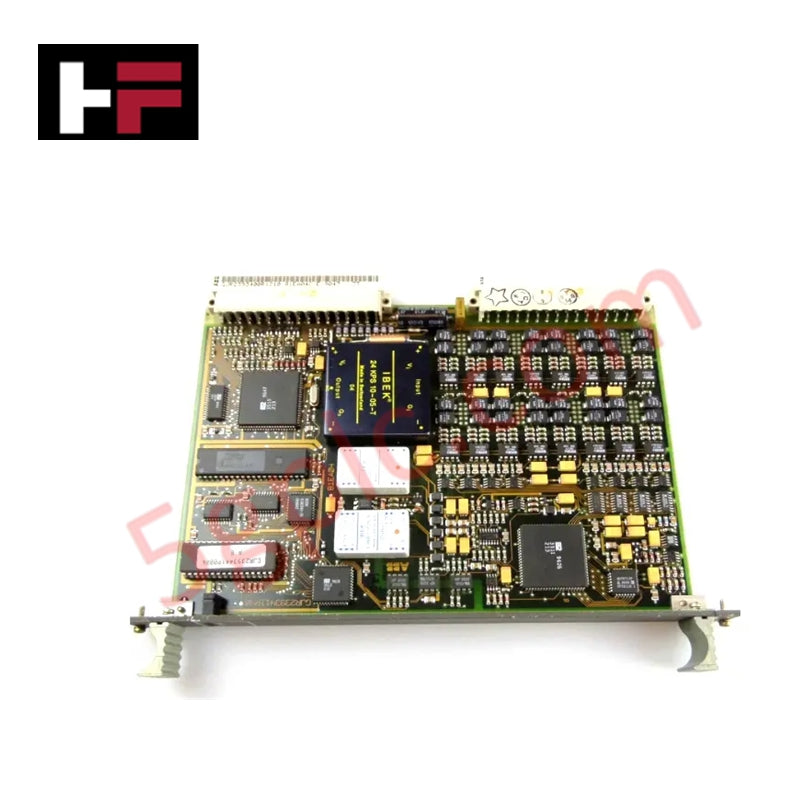

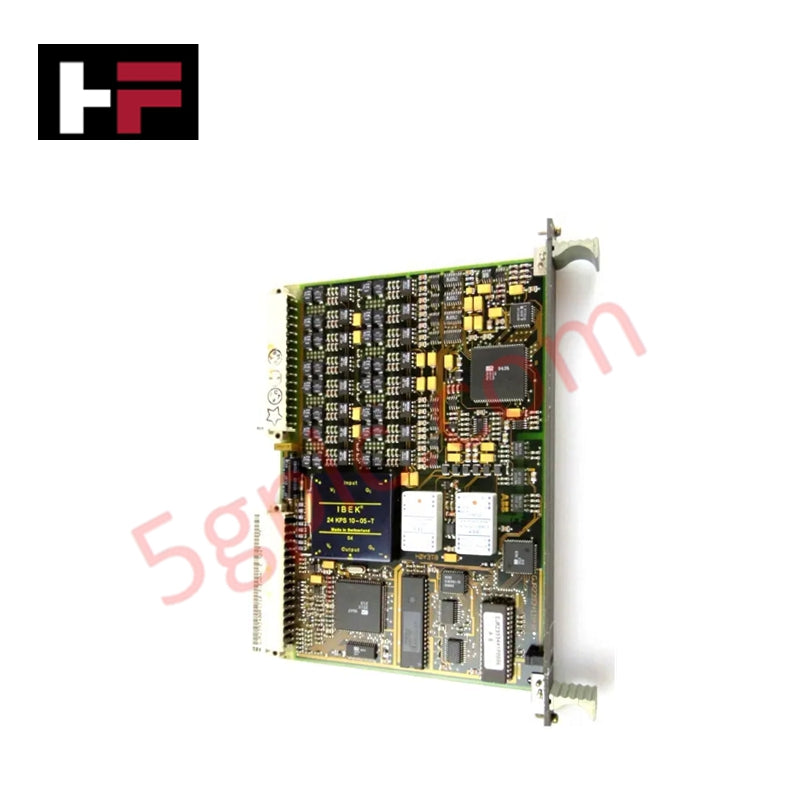

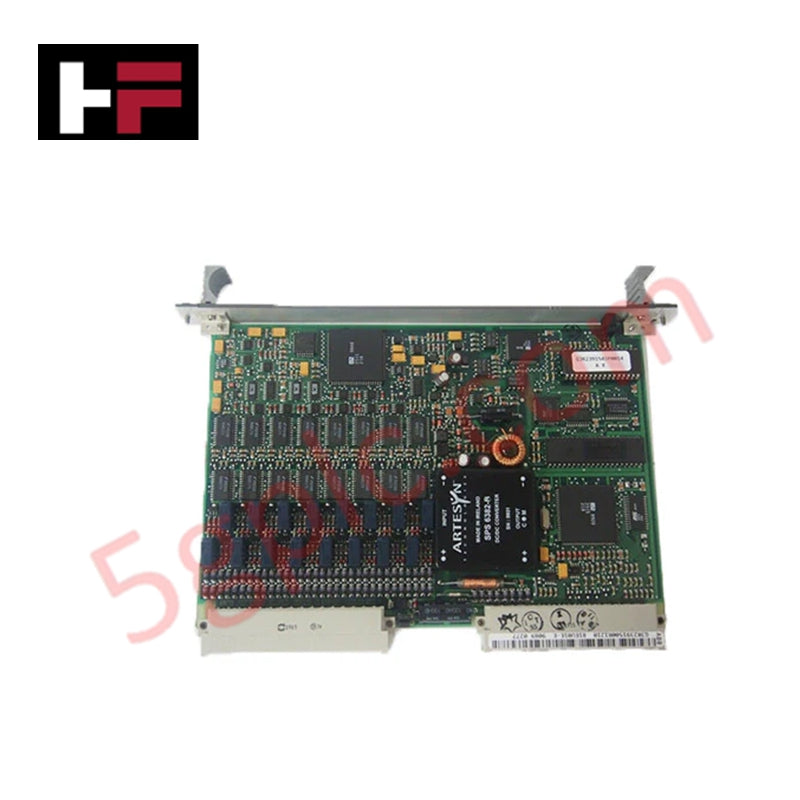

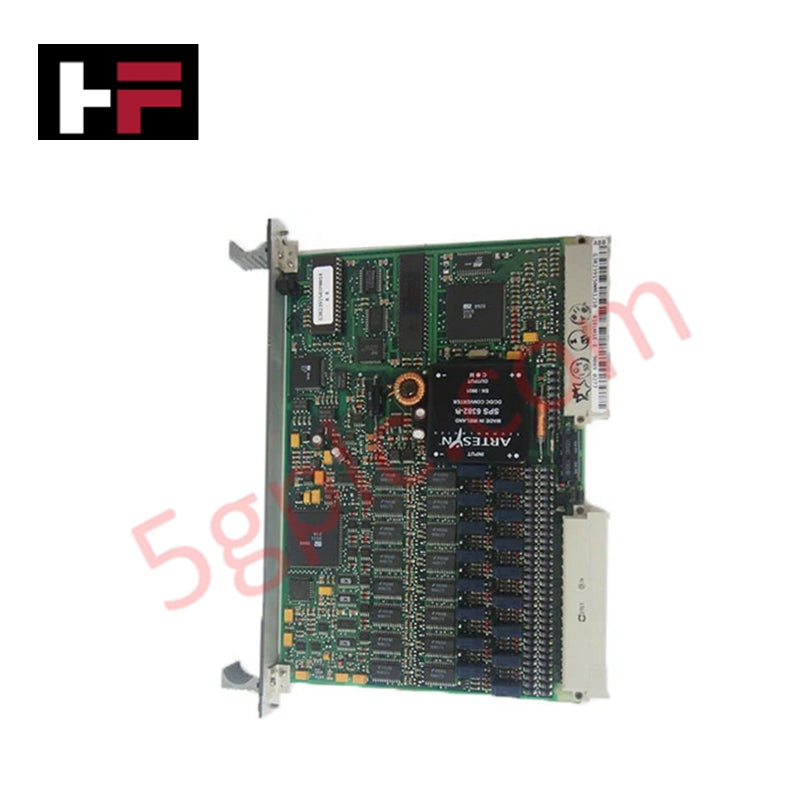

The TU848 3BSE042558R1 is a passive backplane that integrates redundant ModuleBus connections and power distribution. It hosts two communication modules for seamless failover and fault-tolerant process control. Featuring dedicated terminal blocks for dual 24V DC power inputs, it ensures power redundancy. The robust DIN-rail mountable housing includes mechanical keying to prevent incompatible module installation. With no active electronics, the TU848 maximizes MTBF, ensuring high reliability in demanding industrial environments.

Specifications

-

Manufacturer: ABB

-

Model Number: TU848 (3BSE042558R1)

-

Product Type: Redundant Module Termination Unit

-

Supported Modules: Dual CI840 Communication Interfaces

-

Input Voltage: 24 V DC (Redundant dual feeds)

-

Maximum Current: 5 A

-

Bus Interface: Redundant ModuleBus

-

Mounting: 35mm DIN Rail

-

Protection Class: IP20

-

Operating Temperature: -25 to +70 °C

-

Weight: 0.54 kg

Features

-

Redundancy-Ready Architecture: Specifically built for dual-interface setups to eliminate single points of failure in the communication network.

-

Dual Power Feed Management: Accommodates two independent power sources to ensure the I/O cluster remains energized during a power supply fault.

-

Hot-Swap Support: Enables the replacement of a faulty communication module without interrupting the partner module or the active control process.

-

Reliable Passive Backplane: Minimizes internal failure risks by utilizing hardware-based signal routing without active electronic components.

-

Mechanical Safety Coding: Features integrated physical keying pins to ensure only compatible module types are seated, enhancing site safety.

-

Industrial Durability: Optimized for high-vibration and high-temperature environments, ensuring long-term stability in process control cabinets.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.