Product Details

Description

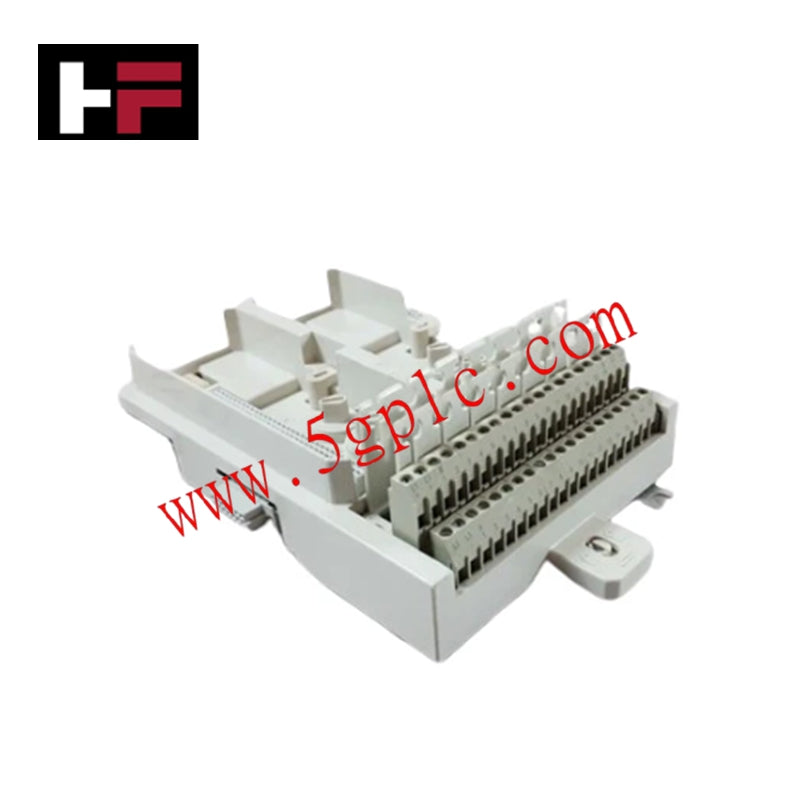

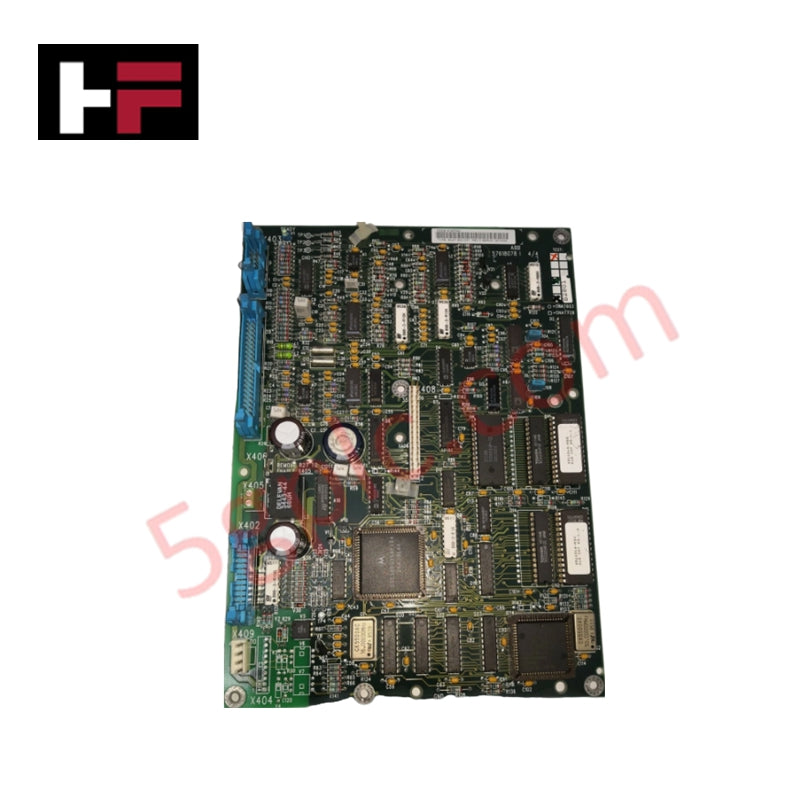

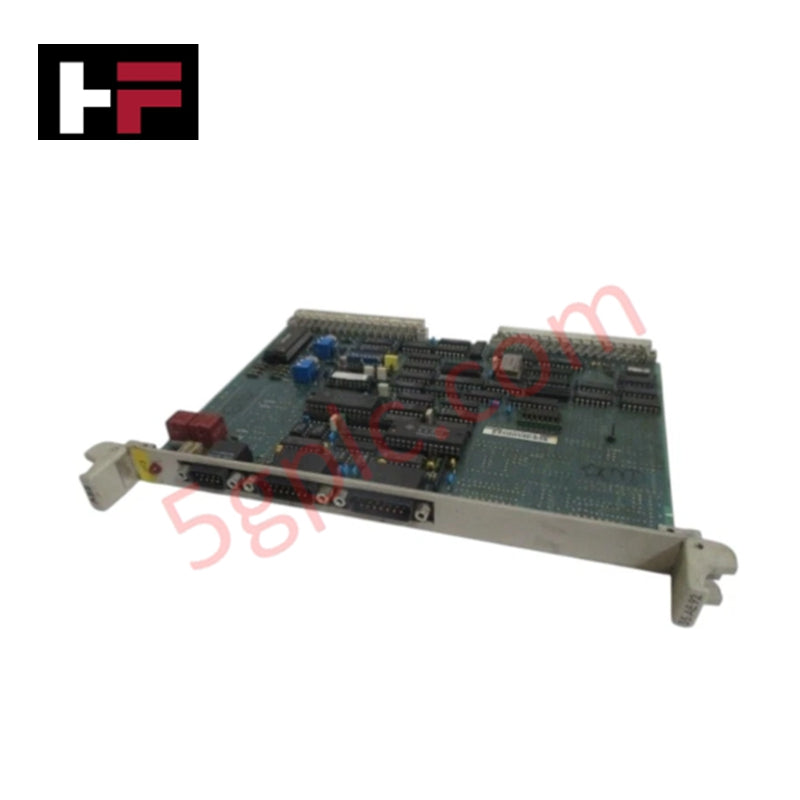

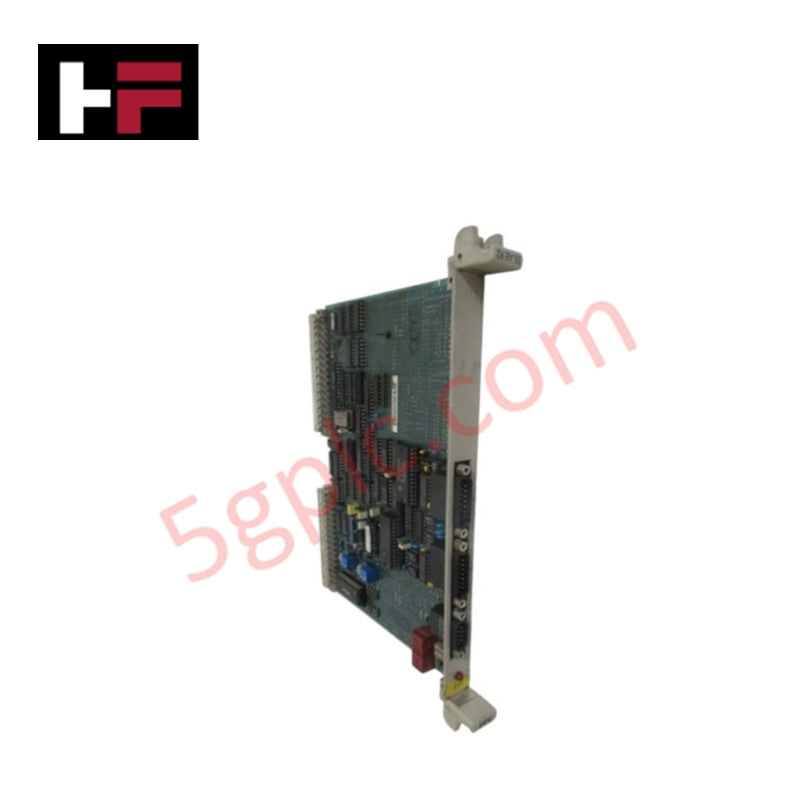

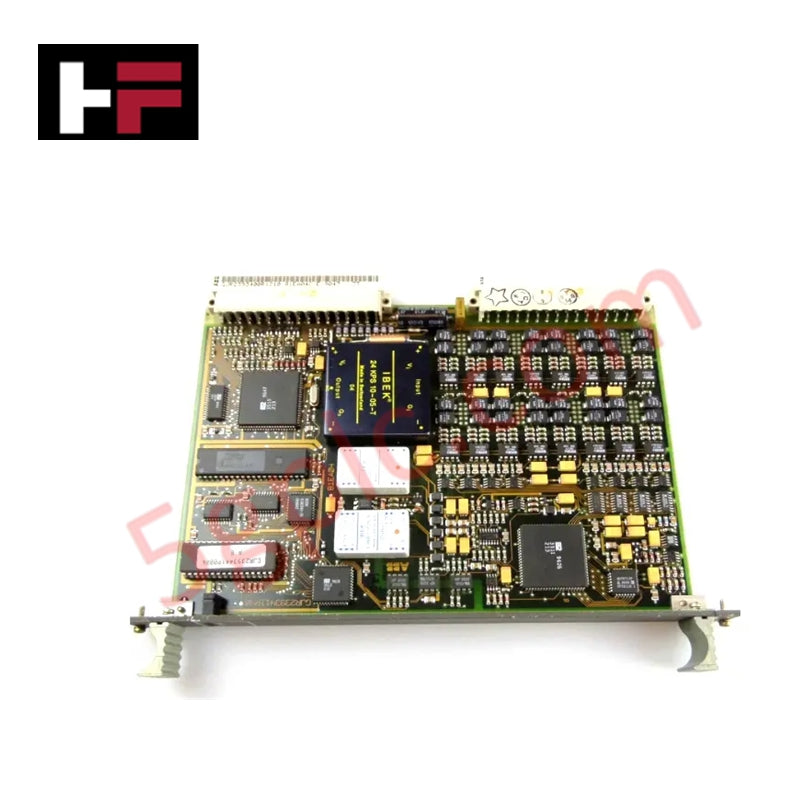

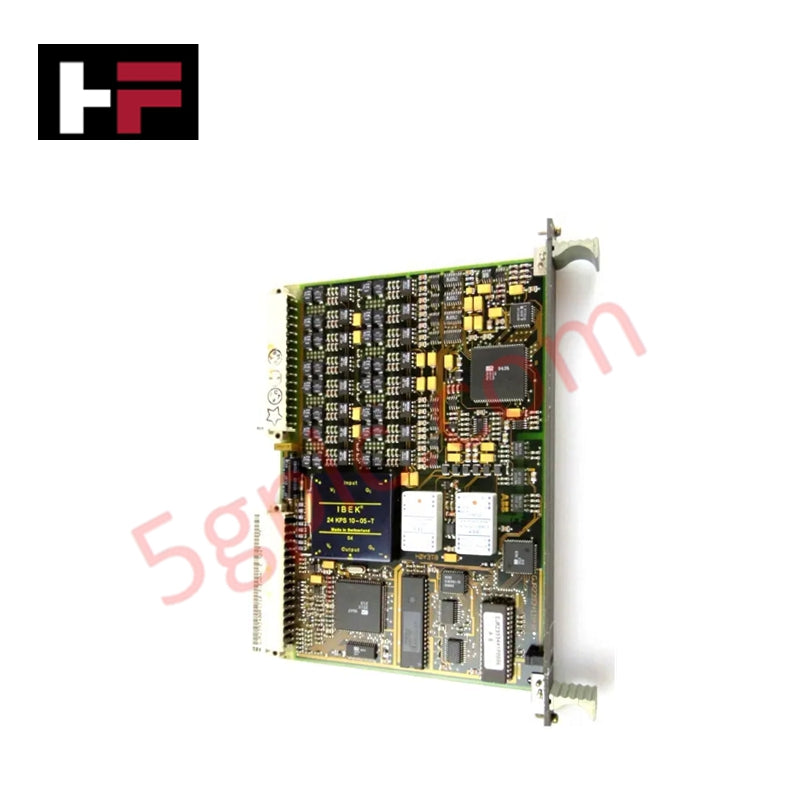

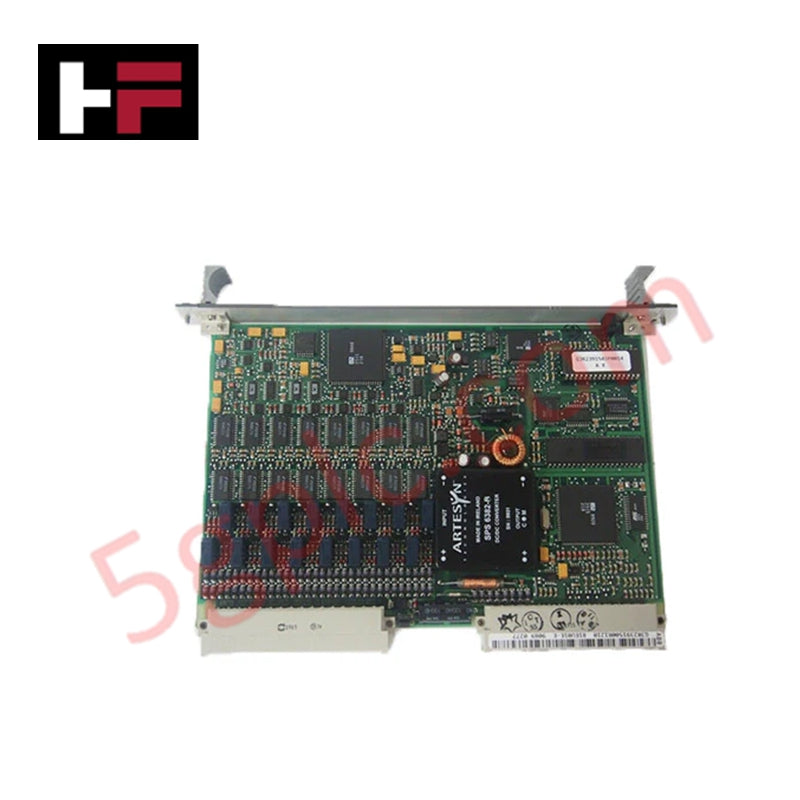

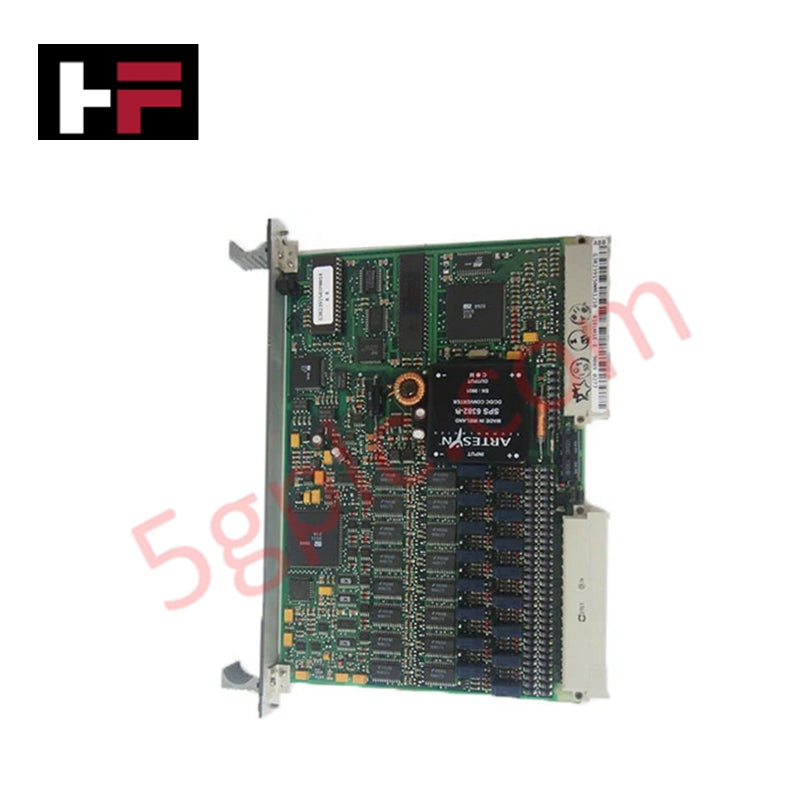

The TU845 3BSE021447R1 is a passive interface that integrates redundant ModuleBus connections and dual power supply routing for increased system reliability. It houses two communication modules for seamless failover, ensuring fault tolerance in critical process control applications. The unit provides dedicated terminal blocks for redundant 24V DC power inputs, securing both data and power paths. Its rugged DIN-rail mountable design includes mechanical keying to prevent configuration errors. With no active electronics, the TU845 maximizes MTBF for the distributed I/O station.

Specifications

-

Manufacturer: ABB

-

Model Number: TU845 (3BSE021447R1)

-

Product Type: Redundant Module Termination Unit

-

Supported Modules: Dual CI810 or CI820 Interfaces

-

Input Voltage: 24 V DC (Redundant inputs)

-

Maximum Current: 5 A

-

Interface: Redundant ModuleBus

-

Mounting: 35mm DIN Rail

-

Protection Rating: IP20

-

Operating Temperature: -25 to +70 °C

-

Weight: 0.55 kg

Features

-

Fault-Tolerant Architecture: Designed specifically for redundant communication setups to eliminate single points of failure in the control network.

-

Dual Power Distribution: Includes separate terminals for two independent power feeds, maintaining I/O cluster operation during a power supply failure.

-

Hot-Swappable Capability: Allows for the replacement of a faulty communication interface while the system is live and the redundant partner is active.

-

Reliable Passive Backplane: Minimizes failure risks by using a hardware-only signal routing design without active electronic components.

-

Mechanical Safety Coding: Built-in physical keying pins ensure that only authorized and compatible module types can be seated in the unit.

-

High-Density Cabinet Solution: Provides a centralized hub for redundant bus and power management within a compact, vibration-resistant footprint.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.