Product Details

Description

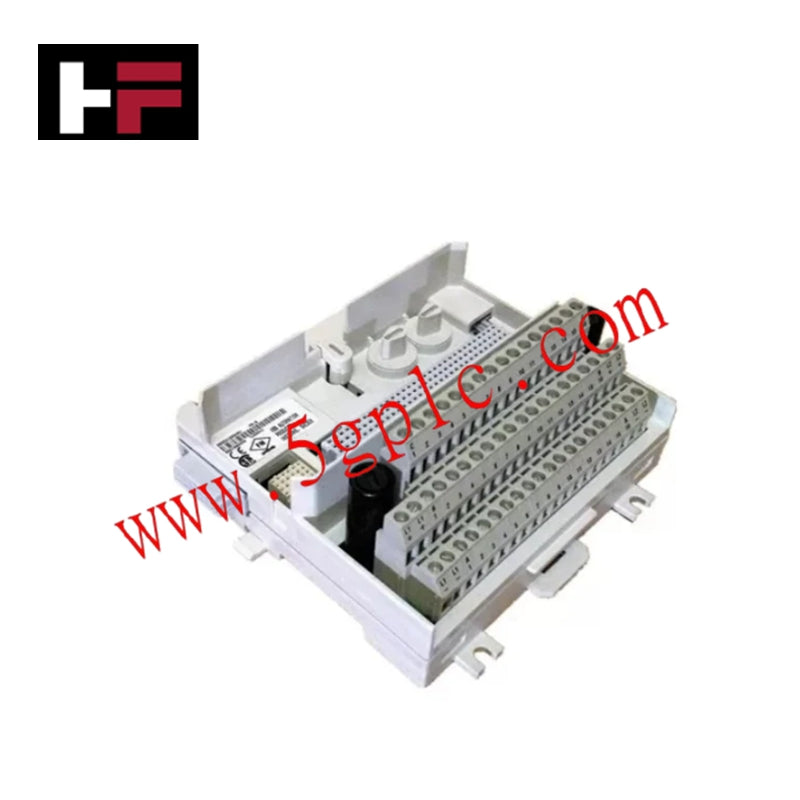

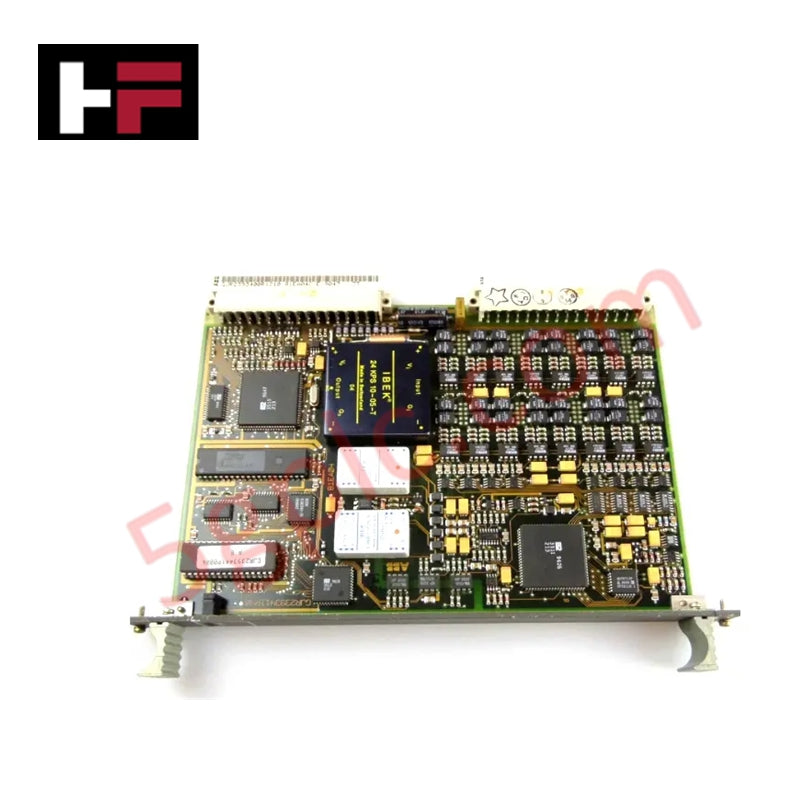

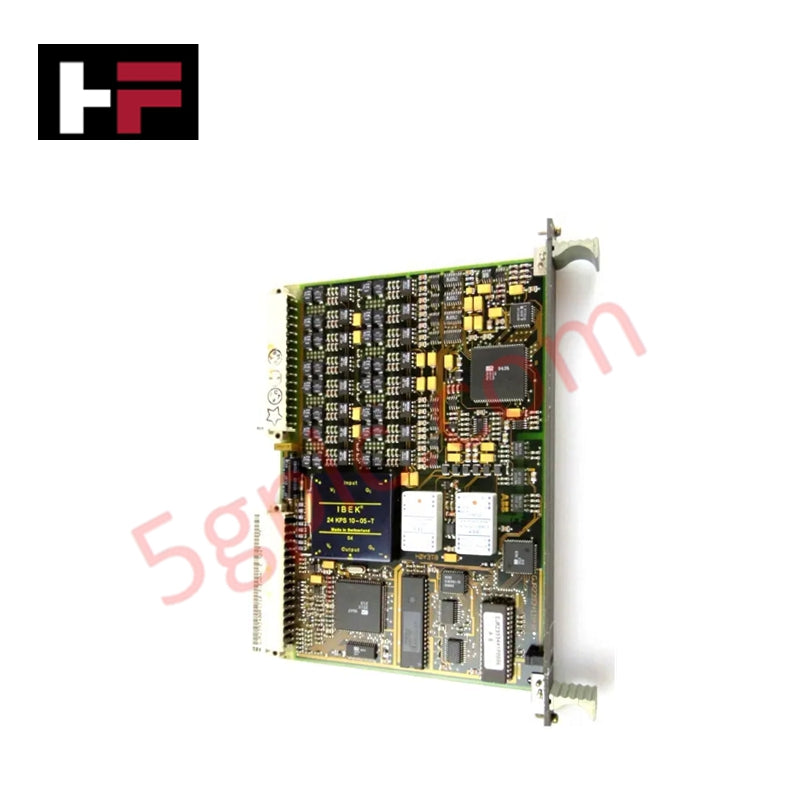

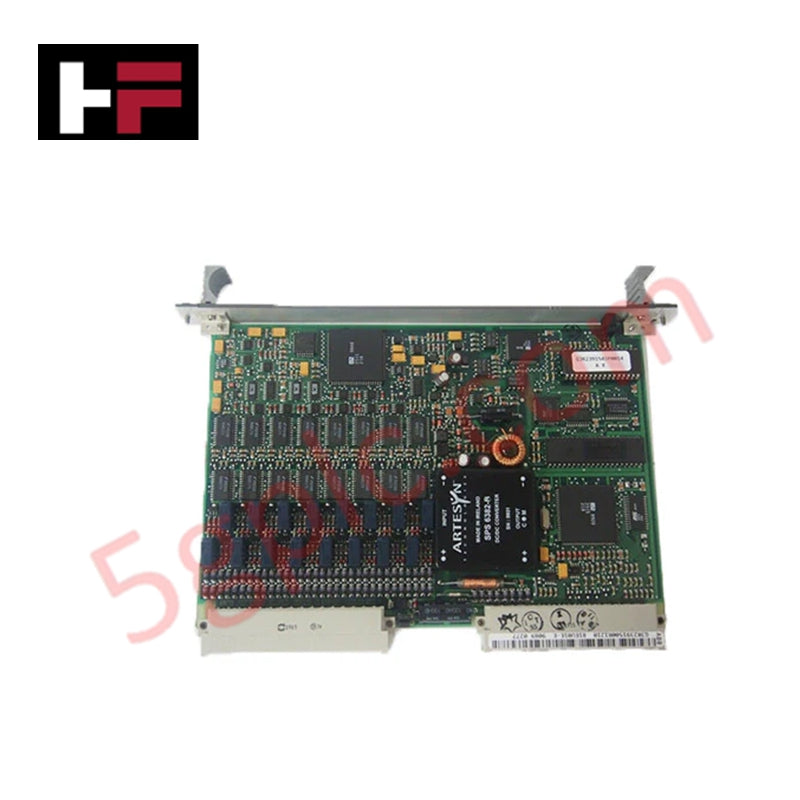

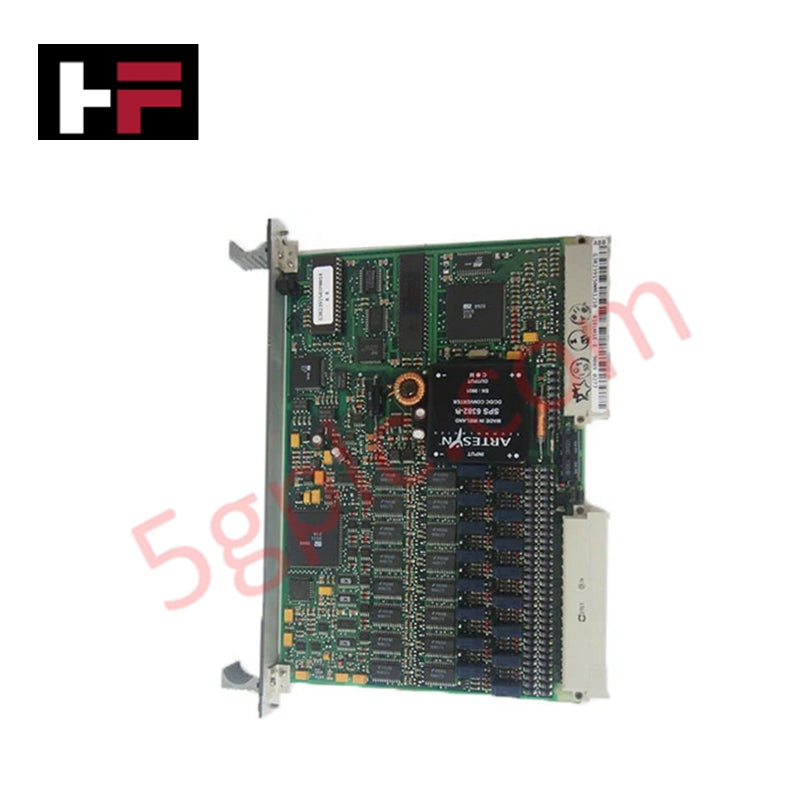

The TU830 3BSE008528R1 is an extended terminal base designed for applications needing individual signal wire termination. It features three rows of screw terminals, providing 24 termination points for 8-channel modules, with dedicated connections for signals, return paths, and power. This passive component ensures system reliability by avoiding active electronics. It supports hot-swapping for easy module replacement without interrupting the process and includes keying pins to prevent incorrect module insertion. It can be mounted vertically or horizontally on 35mm DIN rails.

Specifications

-

Manufacturer: ABB

-

Country of Origin: Sweden

-

Model Number: TU830

-

Order Number: 3BSE008528R1

-

Product Type: Extended Module Termination Unit (MTU)

-

Weight: 0.45 kg

-

Terminal Count: 24 Screw Terminals

-

Maximum Voltage: 50 V DC

-

Current Capacity: 2 A per terminal

-

Wiring Range: 0.2 to 2.5 mm² (24-12 AWG)

-

Mounting: 35mm standard DIN rail

-

Protection Class: IP20

Features

-

Extended Termination Capacity: Equipped with 24 screw-clamp terminals, providing ample space for 3-wire field device connections without external distribution blocks.

-

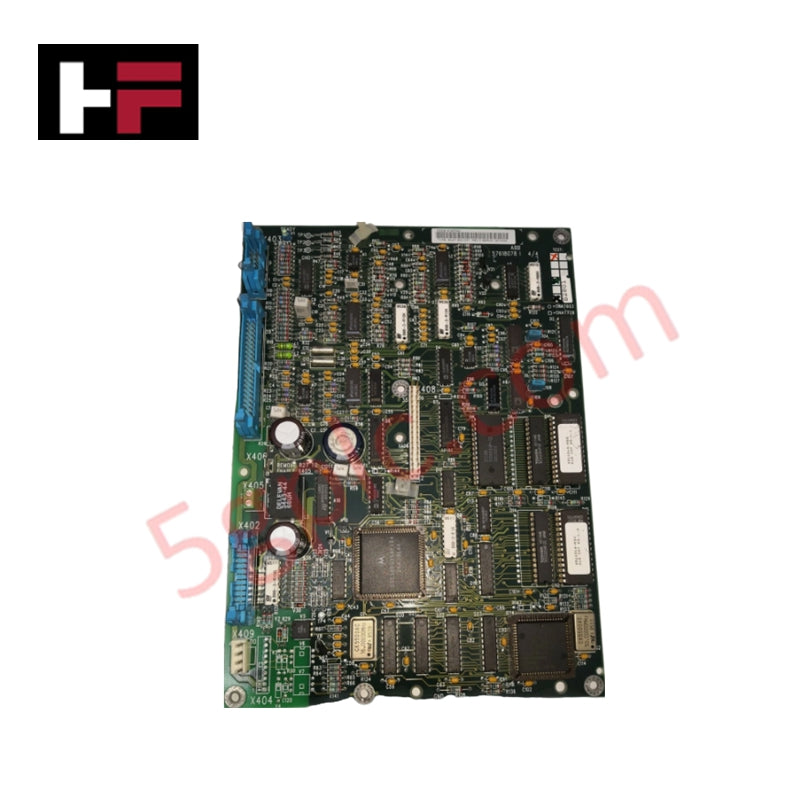

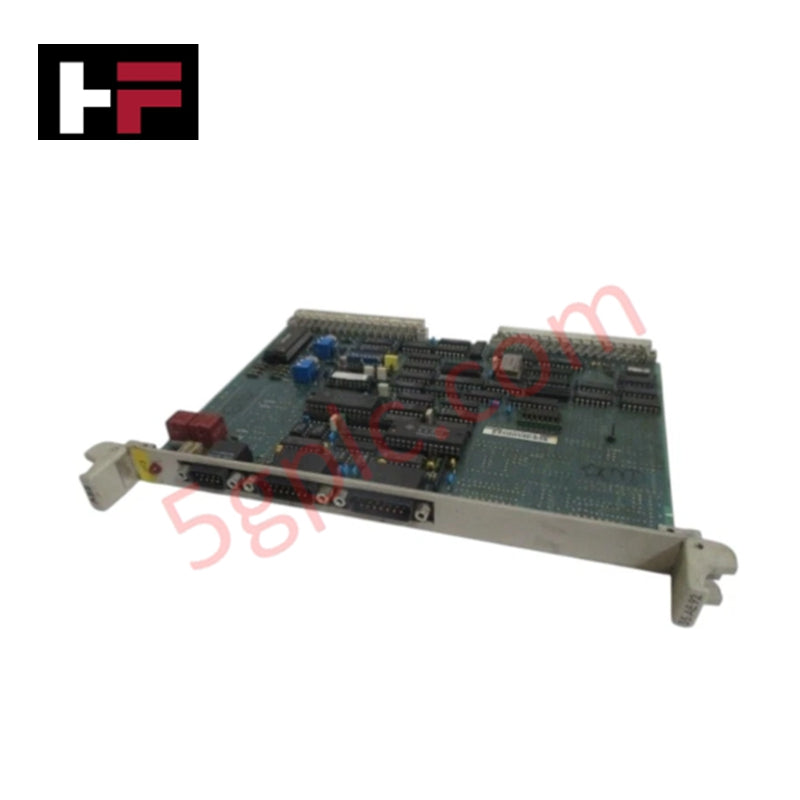

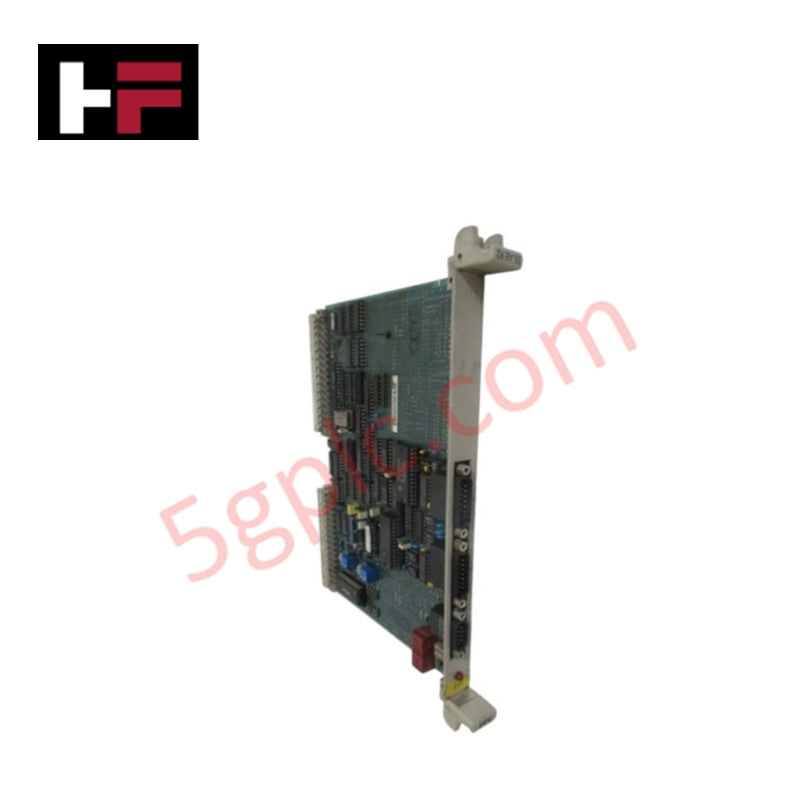

Passive Signal Integrity: Engineered with a hardware-only backplane design to maximize MTBF and ensure transparent signal routing between field and bus.

-

Live Maintenance Capability: Fully supports hot-swap module replacement, enabling system servicing while the cluster remains energized and operational.

-

Mechanical Safety Keying: Integrated physical coding system ensures that only the correct I/O module can be seated, preventing hardware damage from electrical mismatch.

-

Versatile Signal Routing: Accommodates various I/O types, including analog and digital signals, by providing flexible grounding and power distribution points.

-

Rugged Industrial Construction: Designed for stable performance in high-vibration and wide-temperature environments typical of industrial process control.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.