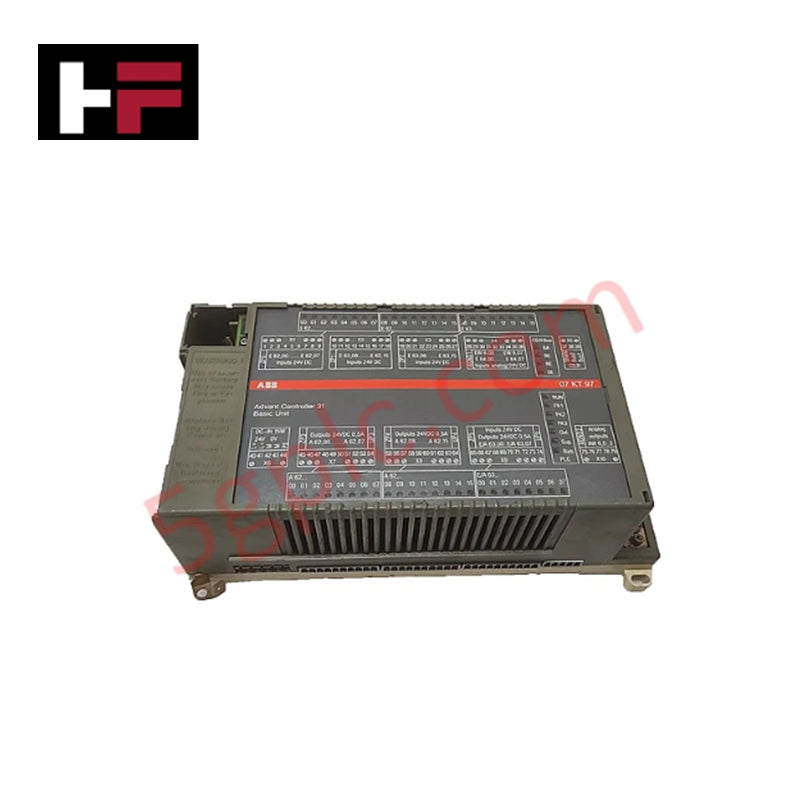

Product Details

Description

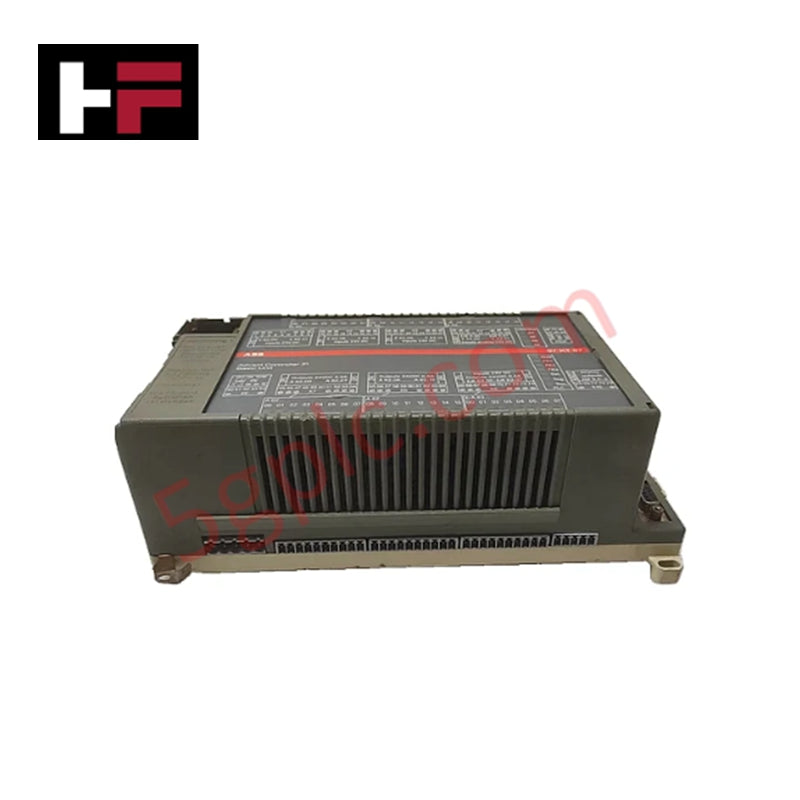

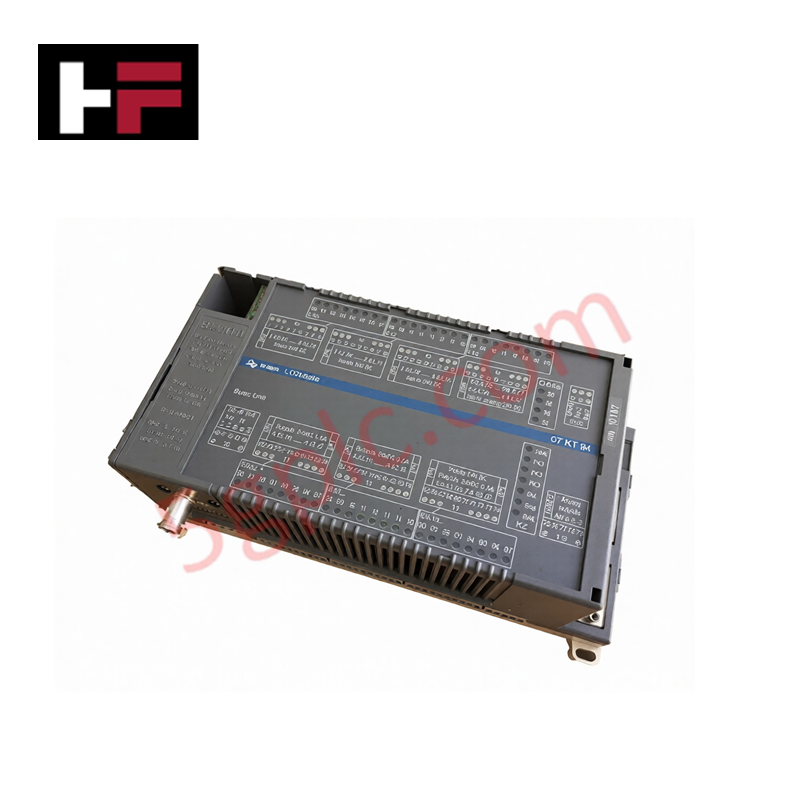

The TU850 3BSE050930R1 is a terminal base that routes field signals to the S800 I/O module and internal ModuleBus. It supports 2-wire or 3-wire connections with 16 termination points in a compact design. Featuring mechanical keying to prevent incorrect module installation, it ensures hardware protection. The TU850 supports hot-swapping of I/O modules, enabling field replacement without disrupting field wiring. Built with rugged construction and screw-clamp terminals, it’s ideal for industrial environments where signal integrity and uptime are crucial.

Specifications

-

Manufacturer: ABB

-

Model Number: TU850 (3BSE050930R1)

-

Product Type: Module Termination Unit (MTU)

-

Terminal Count: 16 Screw Terminals

-

Maximum Rating: 50 V DC / 2 A per channel

-

Mounting Type: 35mm DIN Rail (Horizontal or Vertical)

-

Wire Range: 0.2 to 2.5 mm² (24-12 AWG)

-

Interface: ModuleBus Backplane Connectivity

-

Ingress Protection: IP20

-

Operating Temperature: -25 to +70 °C

-

Weight: 0.40 kg

Features

-

High-Density Signal Management: Provides 16 robust screw terminals for efficient field wiring of analog and digital signals in space-constrained control cabinets.

-

Internal ModuleBus Link: Integrates seamlessly with the S800 I/O bus for high-speed data transmission between field devices and the controller.

-

Error-Proof Hardware Keying: Built-in mechanical coding pins prevent the insertion of incompatible I/O modules, ensuring site safety and equipment protection.

-

Live Serviceability: Designed to support hot-swappable module replacement, minimizing process downtime during routine maintenance or upgrades.

-

Vibration-Resistant Terminals: High-quality screw-clamp design ensures stable electrical contact even in high-vibration manufacturing zones.

-

Passive Reliability: The non-electronic backplane design offers a high MTBF, making it a dependable component for long-term industrial operations.

Additional Information

- 100% Genuine Parts: All products are original and authentic, ensuring reliable industrial performance.

- 30-Day Refund Guarantee: Return any in-stock item within 30 days in original, unopened packaging for a full refund (excluding shipping and fees).

- 12-Month Warranty: Covers defects in materials or workmanship; excludes misuse, normal wear, or unauthorized modifications.

- Worldwide Shipping: We ship via USPS, UPS, FedEx, and DHL. Delivery times vary by country and may be subject to customs or import fees.

- Support & Contact: Technical and warranty assistance is available anytime. Contact us here: Contact.

- Purchase Guidance: Check product specifications and compatibility carefully before ordering to ensure proper application.